What is Global Solder Ribbon and Solder Foil Market?

The Global Solder Ribbon and Solder Foil Market is a specialized segment within the broader electronics and materials industry. Solder ribbons and foils are essential components used in various applications, primarily for creating electrical connections in electronic devices. These materials are typically made from alloys of tin, lead, silver, and other metals, and they come in different forms, such as ribbons and foils, to suit specific manufacturing needs. The market for these products is driven by the growing demand for electronic devices, advancements in technology, and the need for reliable and efficient electrical connections. As industries such as electronics, automotive, and aerospace continue to expand, the demand for high-quality solder materials is expected to rise. Additionally, the shift towards miniaturization and the development of more compact electronic devices further fuel the need for precise and efficient soldering solutions. The market is also influenced by environmental regulations, which have led to the development of lead-free solder materials, catering to the increasing demand for eco-friendly and sustainable manufacturing practices. Overall, the Global Solder Ribbon and Solder Foil Market plays a crucial role in supporting the technological advancements and innovations across various industries.

Lead Free, Leaded in the Global Solder Ribbon and Solder Foil Market:

In the Global Solder Ribbon and Solder Foil Market, the distinction between lead-free and leaded solder materials is significant due to environmental and health considerations. Leaded solder, traditionally composed of a tin-lead alloy, has been widely used for its excellent electrical conductivity and ease of use. However, the presence of lead poses environmental and health risks, leading to stringent regulations and a shift towards lead-free alternatives. Lead-free solder materials are typically made from alloys such as tin-silver-copper (SAC), tin-copper, and tin-bismuth, among others. These alternatives aim to provide similar performance characteristics while eliminating the harmful effects associated with lead. The transition to lead-free soldering has been driven by regulations such as the Restriction of Hazardous Substances (RoHS) directive in the European Union, which restricts the use of certain hazardous materials in electrical and electronic equipment. This shift has prompted manufacturers to invest in research and development to improve the performance and reliability of lead-free solder materials. Despite the challenges associated with lead-free soldering, such as higher melting points and potential reliability issues, the industry has made significant strides in developing solutions that meet the demands of modern electronics manufacturing. The adoption of lead-free solder materials is not only a regulatory requirement but also a reflection of the industry's commitment to sustainability and environmental responsibility. As a result, the market for lead-free solder ribbons and foils is expected to grow, driven by the increasing demand for eco-friendly manufacturing practices and the need to comply with global regulations. On the other hand, leaded solder materials continue to be used in certain applications where their specific properties are required, such as in high-reliability sectors like aerospace and defense. In these cases, the performance benefits of leaded solder, such as its lower melting point and superior wetting properties, outweigh the environmental concerns. However, even in these sectors, there is a gradual shift towards lead-free alternatives as technology advances and more reliable lead-free solutions become available. The balance between lead-free and leaded solder materials in the market is influenced by factors such as regulatory requirements, technological advancements, and the specific needs of different industries. As the Global Solder Ribbon and Solder Foil Market continues to evolve, the focus on developing innovative and sustainable soldering solutions will remain a key driver of growth and development.

Electronics, Automotive, Industrial, Aerospace, Medical, Others in the Global Solder Ribbon and Solder Foil Market:

The Global Solder Ribbon and Solder Foil Market finds extensive usage across various industries, each with its unique requirements and applications. In the electronics industry, solder ribbons and foils are crucial for assembling printed circuit boards (PCBs) and connecting electronic components. The demand for miniaturized and high-performance electronic devices drives the need for precise and reliable soldering solutions. Solder materials ensure strong electrical connections and mechanical stability, which are essential for the functionality and longevity of electronic products. In the automotive industry, solder ribbons and foils are used in the manufacturing of electronic control units (ECUs), sensors, and other electronic components that are integral to modern vehicles. The increasing complexity of automotive electronics, driven by advancements in autonomous driving and electric vehicles, necessitates the use of high-quality solder materials to ensure reliability and safety. The industrial sector also relies on solder ribbons and foils for various applications, including the assembly of industrial machinery and equipment. These materials are used to create durable and efficient electrical connections in harsh environments, where reliability and performance are critical. In the aerospace industry, solder materials are used in the manufacturing of avionics and other electronic systems that require high reliability and performance. The stringent requirements of the aerospace sector demand solder materials that can withstand extreme conditions and provide long-lasting connections. The medical industry utilizes solder ribbons and foils in the production of medical devices and equipment, where precision and reliability are paramount. Solder materials are used to assemble electronic components in devices such as pacemakers, diagnostic equipment, and monitoring systems. Finally, other industries, such as telecommunications and renewable energy, also benefit from the use of solder ribbons and foils in their manufacturing processes. The versatility and reliability of these materials make them indispensable in a wide range of applications, supporting the growth and development of various sectors.

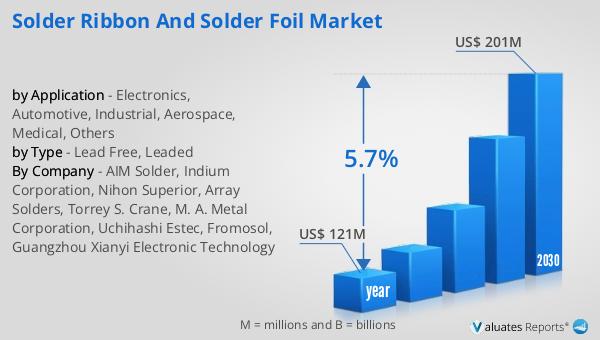

Global Solder Ribbon and Solder Foil Market Outlook:

In 2023, the Global Solder Ribbon and Solder Foil Market was valued at approximately $121 million. This market is anticipated to experience significant growth, reaching an estimated value of $201 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 5.7% over the forecast period. The market's expansion is driven by several factors, including the increasing demand for electronic devices, advancements in technology, and the need for reliable and efficient electrical connections across various industries. As the demand for miniaturized and high-performance electronic devices continues to rise, the need for precise and efficient soldering solutions becomes more critical. Additionally, the shift towards eco-friendly and sustainable manufacturing practices, driven by environmental regulations, further fuels the demand for lead-free solder materials. The market's growth is also supported by the expansion of industries such as automotive, aerospace, and medical, which require high-quality solder materials to ensure the reliability and performance of their products. Overall, the Global Solder Ribbon and Solder Foil Market is poised for significant growth, driven by technological advancements, regulatory requirements, and the increasing demand for innovative and sustainable soldering solutions.

| Report Metric | Details |

| Report Name | Solder Ribbon and Solder Foil Market |

| Accounted market size in year | US$ 121 million |

| Forecasted market size in 2030 | US$ 201 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AIM Solder, Indium Corporation, Nihon Superior, Array Solders, Torrey S. Crane, M. A. Metal Corporation, Uchihashi Estec, Fromosol, Guangzhou Xianyi Electronic Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |