What is Global Solder Paste for Electronic Products Market?

The Global Solder Paste for Electronic Products Market is a crucial segment within the electronics manufacturing industry. Solder paste is a material used to connect electronic components to printed circuit boards (PCBs). It is a mixture of powdered solder and flux, which helps in the soldering process by cleaning and preparing the surfaces to be joined. This market is driven by the increasing demand for electronic devices, which require reliable and efficient soldering solutions. The growth of consumer electronics, automotive electronics, and industrial electronics sectors significantly contributes to the expansion of this market. As technology advances, the need for miniaturization and high-performance electronic devices increases, further boosting the demand for high-quality solder paste. Manufacturers are continuously innovating to develop solder pastes that offer better thermal and electrical conductivity, improved reliability, and environmental compliance. The market is also influenced by regional factors, such as the presence of major electronics manufacturing hubs in Asia-Pacific, North America, and Europe. Overall, the Global Solder Paste for Electronic Products Market plays a vital role in ensuring the functionality and durability of electronic devices, making it an essential component of the electronics manufacturing ecosystem.

in the Global Solder Paste for Electronic Products Market:

Solder paste comes in various types, each catering to different customer needs and applications within the Global Solder Paste for Electronic Products Market. One of the most common types is lead-based solder paste, which has been traditionally used due to its excellent soldering properties and cost-effectiveness. However, due to environmental and health concerns, there has been a significant shift towards lead-free solder pastes. Lead-free solder pastes are made from a combination of metals such as tin, silver, and copper, and are designed to meet regulatory standards like the Restriction of Hazardous Substances (RoHS) directive. These pastes are preferred by customers who prioritize environmental sustainability and compliance with international regulations. Another type is no-clean solder paste, which is formulated to leave minimal residues after soldering, eliminating the need for post-solder cleaning processes. This type is favored by customers looking to reduce manufacturing costs and improve production efficiency. Water-soluble solder paste is another variant, which is designed to be easily cleaned with water after soldering. It is often used in applications where cleanliness is critical, such as in medical devices and aerospace electronics. Customers in these industries choose water-soluble pastes to ensure high reliability and performance of their products. Additionally, there are specialized solder pastes designed for specific applications, such as high-temperature solder pastes used in automotive and industrial electronics, where components are exposed to extreme temperatures. These pastes are formulated to withstand harsh conditions and provide robust solder joints. Customers in these sectors require solder pastes that can maintain their integrity and performance under demanding environments. Furthermore, there are low-temperature solder pastes, which are used in applications where heat-sensitive components are involved. These pastes allow for soldering at lower temperatures, reducing the risk of damaging sensitive components. Customers in the consumer electronics industry often opt for low-temperature pastes to ensure the safety and longevity of their products. The choice of solder paste type depends on various factors, including the specific requirements of the application, regulatory compliance, cost considerations, and the desired performance characteristics. Manufacturers and customers work closely to select the most suitable solder paste for their needs, ensuring optimal results in their electronic products.

Consumer Electronics, Vehicle Electronics, Other in the Global Solder Paste for Electronic Products Market:

The usage of Global Solder Paste for Electronic Products Market spans across various sectors, including consumer electronics, vehicle electronics, and other industries. In the consumer electronics sector, solder paste is essential for assembling a wide range of devices such as smartphones, tablets, laptops, and wearable gadgets. These devices require precise and reliable soldering to ensure their functionality and durability. The miniaturization trend in consumer electronics demands solder pastes that can provide strong and reliable connections in compact spaces. Manufacturers in this sector often opt for lead-free and no-clean solder pastes to meet environmental regulations and streamline production processes. In vehicle electronics, solder paste plays a critical role in the assembly of electronic control units (ECUs), sensors, infotainment systems, and other automotive electronic components. The automotive industry requires solder pastes that can withstand high temperatures and vibrations, ensuring the reliability and safety of electronic systems in vehicles. High-temperature solder pastes are commonly used in this sector to provide robust solder joints that can endure the harsh conditions of automotive environments. Additionally, the shift towards electric and autonomous vehicles is driving the demand for advanced solder pastes that can support the increased complexity and functionality of automotive electronics. Beyond consumer and vehicle electronics, solder paste is also used in various other industries, including telecommunications, aerospace, medical devices, and industrial electronics. In telecommunications, solder paste is used in the assembly of network equipment and communication devices, where reliability and performance are paramount. The aerospace industry requires solder pastes that can withstand extreme temperatures and pressures, ensuring the safety and functionality of avionics systems. In the medical devices sector, solder paste is used in the assembly of diagnostic equipment, monitoring devices, and other medical electronics, where cleanliness and reliability are critical. Water-soluble solder pastes are often chosen for these applications to ensure high levels of cleanliness and performance. In industrial electronics, solder paste is used in the assembly of control systems, sensors, and other electronic components used in manufacturing and automation processes. The choice of solder paste in these industries depends on the specific requirements of the application, including temperature resistance, reliability, and regulatory compliance. Overall, the usage of solder paste in these areas highlights its importance in ensuring the functionality and reliability of electronic products across various sectors.

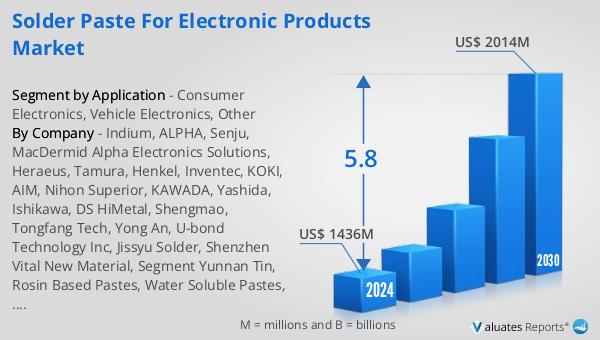

Global Solder Paste for Electronic Products Market Outlook:

The outlook for the Global Solder Paste for Electronic Products Market indicates a promising growth trajectory. It is anticipated that the market will expand from a valuation of US$ 1436 million in 2024 to reach approximately US$ 2014 million by the year 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 5.8% over the forecast period. This projected growth can be attributed to several factors, including the increasing demand for electronic devices across various sectors such as consumer electronics, automotive, telecommunications, and industrial applications. As technology continues to advance, there is a growing need for high-performance and reliable electronic components, which in turn drives the demand for quality solder paste. The shift towards miniaturization and the development of more complex electronic devices also contribute to the market's expansion, as these trends require advanced soldering solutions. Additionally, the emphasis on environmental sustainability and regulatory compliance is pushing manufacturers to adopt lead-free and eco-friendly solder pastes, further fueling market growth. The presence of major electronics manufacturing hubs in regions like Asia-Pacific, North America, and Europe also plays a significant role in the market's development. Overall, the Global Solder Paste for Electronic Products Market is poised for steady growth, driven by technological advancements and increasing demand for electronic devices.

| Report Metric | Details |

| Report Name | Solder Paste for Electronic Products Market |

| Accounted market size in 2024 | US$ 1436 million |

| Forecasted market size in 2030 | US$ 2014 million |

| CAGR | 5.8 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Indium, ALPHA, Senju, MacDermid Alpha Electronics Solutions, Heraeus, Tamura, Henkel, Inventec, KOKI, AIM, Nihon Superior, KAWADA, Yashida, Ishikawa, DS HiMetal, Shengmao, Tongfang Tech, Yong An, U-bond Technology Inc, Jissyu Solder, Shenzhen Vital New Material, Segment Yunnan Tin, Rosin Based Pastes, Water Soluble Pastes, No-clean Pastes |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |