What is VOCs Gas Treatment - Global Market?

VOCs, or Volatile Organic Compounds, are gases emitted from certain solids or liquids, and they include a variety of chemicals that can have short- and long-term adverse health effects. The VOCs Gas Treatment market is a global industry focused on technologies and solutions designed to capture and treat these harmful emissions before they are released into the atmosphere. This market is driven by increasing environmental regulations and the need for industries to comply with air quality standards. VOCs are commonly found in industrial emissions, and their treatment is crucial for reducing air pollution and protecting public health. The global market for VOCs Gas Treatment encompasses a range of technologies, each with its own advantages and applications, tailored to meet the specific needs of different industries. As awareness of environmental issues grows, the demand for effective VOCs gas treatment solutions is expected to rise, making this market an essential component of global efforts to improve air quality and reduce pollution.

Regenerative Thermal Oxidation, Recuperative Thermal Oxidation, Catalytic Oxidation, Adsorption by Activated Carbon, Cryocondensation, Others in the VOCs Gas Treatment - Global Market:

Regenerative Thermal Oxidation (RTO) is a widely used technology in the VOCs Gas Treatment market. It involves the use of high temperatures to oxidize VOCs into carbon dioxide and water vapor, effectively reducing harmful emissions. RTO systems are highly efficient and can handle large volumes of gas with varying concentrations of VOCs. They are particularly suitable for industries with continuous production processes, such as chemical manufacturing and paint production. Recuperative Thermal Oxidation, on the other hand, also uses high temperatures to treat VOCs but incorporates a heat exchanger to recover energy from the exhaust gases. This makes it more energy-efficient compared to traditional thermal oxidation methods. Catalytic Oxidation is another method that uses a catalyst to lower the temperature required for oxidation, making it a more energy-efficient option. It is ideal for applications where the VOC concentration is relatively low. Adsorption by Activated Carbon is a physical process where VOCs are captured on the surface of activated carbon particles. This method is effective for treating low concentrations of VOCs and is commonly used in industries such as pharmaceuticals and food processing. Cryocondensation involves cooling the gas stream to condense VOCs into a liquid form, which can then be collected and disposed of safely. This method is particularly useful for recovering valuable VOCs that can be reused in industrial processes. Other technologies in the VOCs Gas Treatment market include biofiltration and membrane separation, each offering unique benefits and applications. Biofiltration uses microorganisms to degrade VOCs, making it an environmentally friendly option, while membrane separation involves the use of selective membranes to separate VOCs from the gas stream. These technologies are continually evolving, driven by advancements in materials science and engineering, to provide more efficient and cost-effective solutions for VOCs gas treatment.

Petroleum and Petrochemical, Packaging and Printing, Pharmaceuticals, Food Industry, Plastic and Rubber Industry, Iron and Steel Industry, Coatings and Inks, Other in the VOCs Gas Treatment - Global Market:

The usage of VOCs Gas Treatment technologies spans across various industries, each with its own specific requirements and challenges. In the petroleum and petrochemical industry, VOCs are a byproduct of refining processes and storage operations. Effective gas treatment solutions are essential to minimize emissions and comply with stringent environmental regulations. The packaging and printing industry also generates significant VOC emissions, primarily from inks and adhesives. VOCs gas treatment technologies help in capturing these emissions, ensuring a safer working environment and reducing the environmental impact. In the pharmaceutical industry, VOCs are often released during the production of active pharmaceutical ingredients. Gas treatment solutions are crucial for maintaining air quality and protecting the health of workers. The food industry uses VOCs gas treatment to manage emissions from processes such as frying, baking, and flavoring. This not only helps in reducing odors but also ensures compliance with food safety standards. The plastic and rubber industry generates VOCs during the production and processing of materials. Effective gas treatment solutions are necessary to prevent air pollution and protect worker health. In the iron and steel industry, VOCs are emitted during processes such as coke production and metal coating. Gas treatment technologies help in capturing these emissions, contributing to cleaner production processes. The coatings and inks industry relies on VOCs gas treatment to manage emissions from solvents and other volatile compounds used in production. This is essential for reducing environmental impact and ensuring compliance with air quality regulations. Other industries, such as electronics and textiles, also benefit from VOCs gas treatment solutions, which help in managing emissions and improving overall environmental performance.

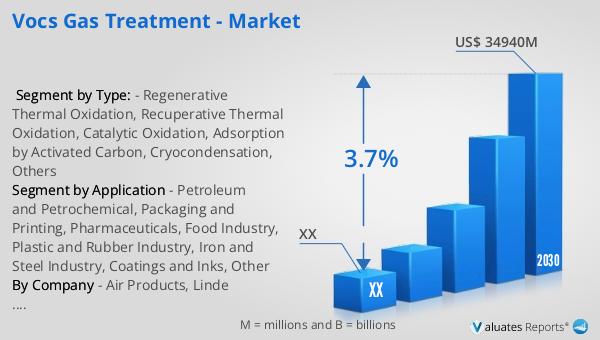

VOCs Gas Treatment - Global Market Outlook:

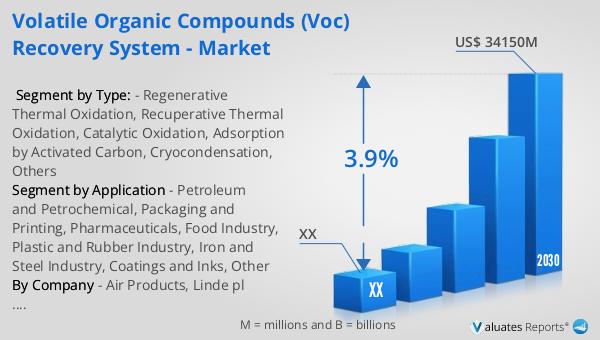

The global market for VOCs Gas Treatment was valued at approximately $27.15 billion in 2023. This market is projected to grow steadily, reaching an estimated value of $34.94 billion by 2030. This growth represents a compound annual growth rate (CAGR) of 3.7% over the forecast period from 2024 to 2030. The increasing demand for VOCs gas treatment solutions is driven by the need for industries to comply with stringent environmental regulations and improve air quality. As awareness of the harmful effects of VOCs on health and the environment continues to rise, industries are investing in advanced gas treatment technologies to reduce emissions and minimize their environmental footprint. The market's growth is also supported by technological advancements that offer more efficient and cost-effective solutions for VOCs gas treatment. As industries across the globe strive to meet sustainability goals and reduce their carbon footprint, the demand for VOCs gas treatment solutions is expected to continue its upward trajectory. This market outlook highlights the importance of VOCs gas treatment in addressing environmental challenges and promoting cleaner industrial processes.

| Report Metric | Details |

| Report Name | VOCs Gas Treatment - Market |

| Forecasted market size in 2030 | US$ 34940 million |

| CAGR | 3.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Air Products, Linde (Praxair), Wärtsilä, Munters, TOYOBO, Taikisha, Nippon Gases, Calgon Carbon Corporation, Condorchem Envitech, Anguil, ComEnCo Systems, POLARIS SRL, Bay Environmental Technology, KVT Process Technology, CECO Environmental, SINOPEC Qingdao Safety Engineering, Naide, ECOTEC, Beijing CEC Environmental Engineering, WELLE Environmental Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |