What is Global Valves for Power Generation Market?

The Global Valves for Power Generation Market is a crucial segment within the broader industrial valves industry, specifically tailored to meet the demands of power generation facilities worldwide. These valves are essential components in power plants, playing a pivotal role in controlling the flow of fluids and gases, ensuring safety, and optimizing operational efficiency. The market encompasses a wide range of valve types, including gate, globe, ball, and butterfly valves, each designed to perform specific functions within power generation systems. As the demand for energy continues to rise globally, driven by population growth and industrialization, the need for efficient and reliable power generation infrastructure becomes increasingly important. This, in turn, fuels the demand for high-quality valves that can withstand the rigorous conditions of power plants, such as high pressure and temperature. The market is characterized by technological advancements aimed at enhancing valve performance, durability, and automation capabilities. Additionally, the shift towards cleaner and more sustainable energy sources is influencing the development and adoption of valves that can support renewable energy technologies. Overall, the Global Valves for Power Generation Market is poised for steady growth, driven by the ongoing expansion and modernization of power generation facilities worldwide.

Gate Valve, Globe Valve, Ball Valve, Butterfly Valve, Others in the Global Valves for Power Generation Market:

In the Global Valves for Power Generation Market, various types of valves play distinct roles, each contributing to the efficient operation of power plants. Gate valves are primarily used for on-off control, allowing or preventing the flow of fluids. They are designed to operate fully open or fully closed, minimizing pressure drop across the valve. This makes them ideal for applications where the valve remains either fully open or closed for extended periods, such as in the main steam lines of power plants. Globe valves, on the other hand, are used for regulating flow. They provide precise control over fluid flow and are commonly used in applications where throttling is required. Their design allows for a linear motion of the disc, which can be adjusted to control the flow rate, making them suitable for feedwater systems and cooling water circuits. Ball valves are known for their durability and reliability, offering tight sealing with minimal leakage. They are used in applications where quick shut-off is necessary, such as in emergency shutdown systems. The design of ball valves allows for a 90-degree turn to open or close the valve, providing fast and efficient operation. Butterfly valves are lightweight and compact, making them suitable for applications where space is limited. They are used for isolating or regulating flow and are commonly found in cooling water, air, and gas applications. Their simple design allows for quick operation and low-pressure drop, making them energy-efficient. Other types of valves, such as check valves and pressure relief valves, also play critical roles in power generation systems. Check valves prevent backflow, ensuring that fluids flow in the desired direction, while pressure relief valves protect equipment from overpressure conditions by releasing excess pressure. Each type of valve is selected based on its specific characteristics and the requirements of the application, ensuring optimal performance and safety in power generation facilities.

Thermal Power Plant, Hydroelectric Power Plant, Nuclear Power Plant, Others in the Global Valves for Power Generation Market:

Valves are integral to the operation of various types of power plants, each with unique requirements and challenges. In thermal power plants, which rely on the combustion of fossil fuels to generate electricity, valves are used extensively to control the flow of steam, water, and fuel. Gate valves are commonly used in the main steam lines to isolate sections of the plant for maintenance or emergencies. Globe valves are used in feedwater systems to regulate the flow of water into the boiler, ensuring optimal steam generation. Ball valves are employed in fuel supply lines for quick shut-off in case of emergencies, while butterfly valves are used in cooling water systems to regulate flow and maintain efficient heat exchange. In hydroelectric power plants, valves play a crucial role in controlling the flow of water through turbines. Butterfly valves are often used to regulate water flow, allowing for precise control of turbine speed and power output. Gate valves are used to isolate sections of the plant for maintenance, while check valves prevent backflow and protect equipment from damage. In nuclear power plants, valves are critical for ensuring safety and operational efficiency. Globe valves are used in reactor cooling systems to regulate the flow of coolant, maintaining optimal reactor temperature. Ball valves are employed in emergency shutdown systems for quick isolation of critical components. Pressure relief valves are essential for protecting equipment from overpressure conditions, ensuring the safety of the plant and personnel. Other types of power plants, such as geothermal and solar thermal, also rely on valves for efficient operation. In geothermal plants, valves are used to control the flow of steam and hot water from underground reservoirs, while in solar thermal plants, they regulate the flow of heat transfer fluids. Each type of power plant has specific requirements for valve performance, durability, and reliability, making the selection of the right valve critical for efficient and safe operation.

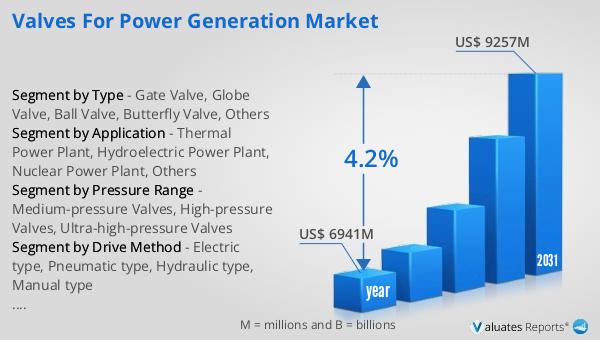

Global Valves for Power Generation Market Outlook:

The global market for valves used in power generation was valued at approximately $6.941 billion in 2024. It is anticipated to grow significantly, reaching an estimated value of $9.257 billion by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.2% over the forecast period. This upward trend reflects the increasing demand for energy and the ongoing expansion and modernization of power generation infrastructure worldwide. As power plants continue to evolve to meet the growing energy needs, the demand for high-quality, efficient, and reliable valves is expected to rise. These valves are essential for controlling the flow of fluids and gases, ensuring safety, and optimizing the operational efficiency of power generation facilities. The market's growth is also driven by technological advancements aimed at enhancing valve performance, durability, and automation capabilities. Additionally, the shift towards cleaner and more sustainable energy sources is influencing the development and adoption of valves that can support renewable energy technologies. Overall, the Global Valves for Power Generation Market is poised for steady growth, driven by the ongoing expansion and modernization of power generation facilities worldwide.

| Report Metric | Details |

| Report Name | Valves for Power Generation Market |

| Accounted market size in year | US$ 6941 million |

| Forecasted market size in 2031 | US$ 9257 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Drive Method |

|

| Segment by Pressure Range |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Emerson, Flowserve, Baker Hughes, Crane, Watts, Kitz, IMI, KSB, VTI Valves, HP Valves, Bray, SLB, AVK, Conval, MOGAS, Descote, DeZURIK, ARI Armaturen, Neway Valve (Suzhou), Jiangsu Shentong Valve, SUFA Technology Industry, Chongqing Chuanyi Automation, Wuxi SMART AUTO-CONTROL Engineering, HE Harbin POWER PLANT Valve |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |