What is Oil and Gas Corrosion Inhibitor - Global Market?

Oil and gas corrosion inhibitors are essential chemicals used to protect metal surfaces in the oil and gas industry from the damaging effects of corrosion. Corrosion is a natural process that occurs when metals react with environmental elements like oxygen, water, and other chemicals, leading to the deterioration of metal surfaces. In the oil and gas sector, corrosion can cause significant damage to pipelines, drilling equipment, and storage tanks, leading to costly repairs and potential safety hazards. The global market for oil and gas corrosion inhibitors is a crucial segment of the industry, as it provides solutions to extend the lifespan of equipment and infrastructure. These inhibitors work by forming a protective layer on metal surfaces, preventing corrosive substances from coming into contact with the metal. The demand for corrosion inhibitors is driven by the need to maintain the integrity and efficiency of oil and gas operations, reduce maintenance costs, and ensure environmental safety. As the industry continues to grow and expand into new regions, the market for corrosion inhibitors is expected to see steady growth, driven by technological advancements and increasing awareness of the importance of corrosion prevention.

Organic Corrosion Inhibitor, Inorganic Corrosion Inhibitor in the Oil and Gas Corrosion Inhibitor - Global Market:

Organic and inorganic corrosion inhibitors are two primary types of chemicals used in the oil and gas industry to combat corrosion. Organic corrosion inhibitors are compounds that contain carbon and are typically derived from natural sources. They work by adsorbing onto the metal surface and forming a protective film that prevents corrosive agents from reaching the metal. These inhibitors are often used in environments where the presence of water and oxygen can accelerate corrosion. Organic inhibitors are favored for their ability to provide long-lasting protection and their compatibility with various metal types. They are particularly effective in preventing corrosion in pipelines and storage tanks, where the presence of moisture and oxygen can lead to rapid deterioration. Inorganic corrosion inhibitors, on the other hand, are compounds that do not contain carbon and are typically derived from minerals or synthetic sources. They work by reacting with the metal surface to form a protective layer that prevents corrosion. Inorganic inhibitors are often used in high-temperature environments where organic inhibitors may not be effective. They are particularly useful in drilling operations, where the presence of high temperatures and pressures can accelerate corrosion. Inorganic inhibitors are also used in transportation systems, where they help to protect pipelines and other infrastructure from the corrosive effects of transported fluids. Both organic and inorganic inhibitors play a crucial role in the oil and gas industry, providing essential protection to equipment and infrastructure and helping to ensure the safe and efficient operation of oil and gas facilities. The choice between organic and inorganic inhibitors depends on various factors, including the specific environmental conditions, the type of metal being protected, and the desired level of protection. As the industry continues to evolve, the development of new and more effective corrosion inhibitors is expected to drive further growth in the global market for oil and gas corrosion inhibitors.

Oil and Gas Drilling System, Oil and Gas Gathering and Transportation Systems, Others in the Oil and Gas Corrosion Inhibitor - Global Market:

The usage of oil and gas corrosion inhibitors is critical in various areas of the industry, including oil and gas drilling systems, gathering and transportation systems, and other related operations. In oil and gas drilling systems, corrosion inhibitors are used to protect drilling equipment and infrastructure from the harsh conditions encountered during drilling operations. The presence of high temperatures, pressures, and corrosive fluids can lead to rapid deterioration of metal surfaces, resulting in equipment failure and costly downtime. Corrosion inhibitors help to extend the lifespan of drilling equipment by forming a protective barrier on metal surfaces, preventing corrosive agents from causing damage. In oil and gas gathering and transportation systems, corrosion inhibitors are used to protect pipelines and other infrastructure from the corrosive effects of transported fluids. These systems are often exposed to a variety of corrosive substances, including water, carbon dioxide, and hydrogen sulfide, which can cause significant damage to metal surfaces. Corrosion inhibitors help to prevent this damage by forming a protective layer on the metal surface, reducing the risk of leaks and ensuring the safe and efficient transport of oil and gas. In addition to drilling and transportation systems, corrosion inhibitors are also used in other areas of the oil and gas industry, including storage tanks, refineries, and processing facilities. In these environments, corrosion inhibitors help to protect metal surfaces from the corrosive effects of stored or processed fluids, reducing maintenance costs and ensuring the safe operation of facilities. The use of corrosion inhibitors is essential for maintaining the integrity and efficiency of oil and gas operations, reducing the risk of equipment failure, and ensuring environmental safety. As the industry continues to grow and expand into new regions, the demand for corrosion inhibitors is expected to increase, driven by the need for reliable and effective corrosion protection solutions.

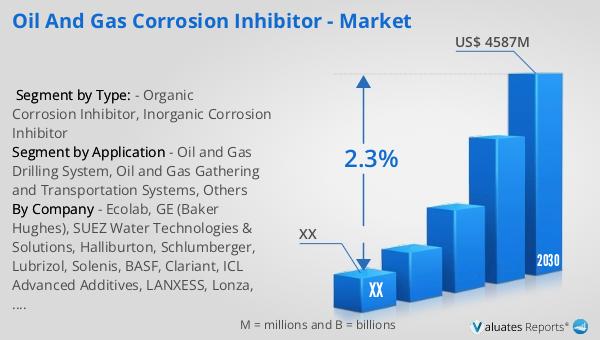

Oil and Gas Corrosion Inhibitor - Global Market Outlook:

The global market for oil and gas corrosion inhibitors was valued at approximately US$ 3,912 million in 2023. It is projected to reach an adjusted size of US$ 4,587 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.3% during the forecast period from 2024 to 2030. These inhibitors are vital chemicals extensively utilized in the oil and gas extraction industry to mitigate the corrosive effects on metal pipes and equipment. Corrosion inhibitors play a crucial role in prolonging the lifespan of infrastructure and equipment by forming a protective barrier that prevents corrosive substances from interacting with metal surfaces. This not only helps in maintaining operational efficiency but also significantly reduces maintenance costs and enhances safety measures. The steady growth in the market is attributed to the increasing awareness of the importance of corrosion prevention, coupled with technological advancements that have led to the development of more effective and environmentally friendly inhibitors. As the oil and gas industry continues to expand and explore new regions, the demand for reliable corrosion protection solutions is expected to rise, further driving the market for corrosion inhibitors. This growth underscores the critical role that corrosion inhibitors play in ensuring the longevity and safety of oil and gas operations worldwide.

| Report Metric | Details |

| Report Name | Oil and Gas Corrosion Inhibitor - Market |

| Forecasted market size in 2030 | US$ 4587 million |

| CAGR | 2.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Ecolab, GE (Baker Hughes), SUEZ Water Technologies & Solutions, Halliburton, Schlumberger, Lubrizol, Solenis, BASF, Clariant, ICL Advanced Additives, LANXESS, Lonza, Daubert Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |