What is Solar Photovoltaic Wafer - Global Market?

Solar photovoltaic wafers are a crucial component in the solar energy industry, serving as the foundational material for solar cells that convert sunlight into electricity. These wafers are thin slices of semiconductor material, typically silicon, which is the most abundant element on Earth. The global market for solar photovoltaic wafers is driven by the increasing demand for renewable energy sources, as countries worldwide strive to reduce their carbon footprints and transition to cleaner energy solutions. The market is characterized by rapid technological advancements, which aim to improve the efficiency and reduce the cost of solar energy production. As the world continues to embrace sustainable energy, the solar photovoltaic wafer market is expected to grow significantly, driven by government incentives, declining costs of solar technology, and the rising awareness of environmental issues. The market is also influenced by the supply chain dynamics, with key players investing in research and development to enhance the performance and durability of solar wafers. Overall, the solar photovoltaic wafer market plays a pivotal role in the global shift towards renewable energy, offering a sustainable solution to meet the growing energy demands.

Monocrystalline Wafer, Multicrystalline Wafer in the Solar Photovoltaic Wafer - Global Market:

Monocrystalline and multicrystalline wafers are two primary types of solar photovoltaic wafers, each with distinct characteristics and applications in the global market. Monocrystalline wafers are made from a single, continuous crystal structure, which gives them a uniform appearance and higher efficiency compared to their multicrystalline counterparts. These wafers are typically more expensive to produce due to the complex manufacturing process, which involves growing a single crystal of silicon. However, their higher efficiency makes them a popular choice for residential and commercial solar installations where space is limited, and maximum energy output is desired. On the other hand, multicrystalline wafers, also known as polycrystalline wafers, are composed of multiple silicon crystals. They are generally less expensive to produce, as the manufacturing process is simpler and involves casting molten silicon into molds. While multicrystalline wafers are less efficient than monocrystalline wafers, they offer a cost-effective solution for large-scale solar projects where space is not a constraint. The choice between monocrystalline and multicrystalline wafers often depends on the specific requirements of the solar project, including budget, space availability, and desired energy output. In recent years, advancements in technology have led to the development of high-efficiency multicrystalline wafers, narrowing the efficiency gap between the two types. This has further fueled the growth of the solar photovoltaic wafer market, as consumers and businesses seek to balance cost and performance in their solar energy systems. Additionally, the global market for solar photovoltaic wafers is influenced by regional factors, such as government policies, availability of raw materials, and the level of technological expertise. For instance, countries with abundant silicon resources and advanced manufacturing capabilities are well-positioned to dominate the market. Furthermore, the increasing focus on sustainability and environmental impact has led to innovations in wafer production, such as the use of recycled materials and energy-efficient manufacturing processes. These developments not only enhance the sustainability of solar energy but also contribute to the overall growth of the solar photovoltaic wafer market. As the demand for clean energy continues to rise, the market for monocrystalline and multicrystalline wafers is expected to expand, driven by the need for efficient and cost-effective solar solutions.

P-Type Battery, N-Type Battery in the Solar Photovoltaic Wafer - Global Market:

Solar photovoltaic wafers are integral to the functioning of both P-type and N-type batteries, which are essential components in solar energy systems. P-type batteries, or P-type solar cells, are made using silicon wafers doped with boron, creating a positive charge. These cells are the most common type used in the solar industry due to their cost-effectiveness and reliable performance. P-type solar cells are typically used in residential and commercial solar installations, where they convert sunlight into electricity with a reasonable efficiency rate. The global market for solar photovoltaic wafers plays a crucial role in the production of P-type batteries, as manufacturers strive to improve the efficiency and reduce the cost of these cells. On the other hand, N-type batteries, or N-type solar cells, are made using silicon wafers doped with phosphorus, resulting in a negative charge. N-type solar cells are known for their higher efficiency and better performance in low-light conditions compared to P-type cells. They are often used in high-performance solar applications, such as large-scale solar farms and specialized solar panels for space missions. The global market for solar photovoltaic wafers is instrumental in the development of N-type batteries, as it provides the necessary materials and technological advancements to enhance their performance. The choice between P-type and N-type batteries often depends on the specific requirements of the solar project, including budget, efficiency needs, and environmental conditions. As the demand for renewable energy continues to grow, the market for solar photovoltaic wafers is expected to expand, driven by the need for efficient and cost-effective solar solutions. Manufacturers are investing in research and development to improve the performance of both P-type and N-type batteries, ensuring that they meet the evolving needs of the solar industry. Additionally, the global market for solar photovoltaic wafers is influenced by regional factors, such as government policies, availability of raw materials, and the level of technological expertise. Countries with advanced manufacturing capabilities and a strong focus on renewable energy are well-positioned to lead the market, driving innovation and growth in the solar industry. Overall, the solar photovoltaic wafer market plays a vital role in the development and deployment of P-type and N-type batteries, offering a sustainable solution to meet the growing energy demands.

Solar Photovoltaic Wafer - Global Market Outlook:

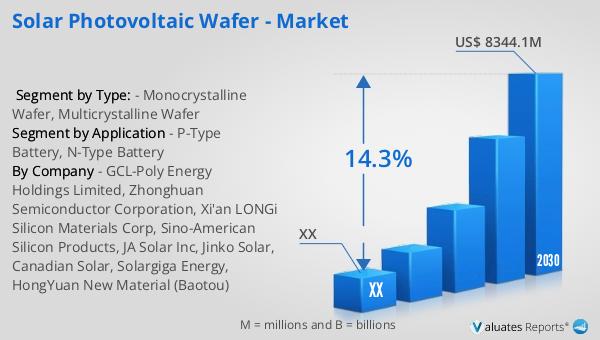

The global market for solar photovoltaic wafers was valued at approximately $3,277 million in 2023, with projections indicating a significant increase to around $8,344.1 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 14.3% during the forecast period from 2024 to 2030. According to the International Energy Agency, China holds a dominant position in the market, with its share in all key products of the supply chain exceeding 80%. This dominance is attributed to China's extensive manufacturing capabilities, abundant raw material resources, and strong government support for the renewable energy sector. The rapid expansion of the solar photovoltaic wafer market is driven by the increasing demand for clean energy solutions, as countries worldwide strive to reduce their carbon emissions and transition to sustainable energy sources. The market is characterized by technological advancements, which aim to improve the efficiency and reduce the cost of solar energy production. As the world continues to embrace renewable energy, the solar photovoltaic wafer market is expected to play a crucial role in meeting the growing energy demands. The market's growth is further supported by government incentives, declining costs of solar technology, and the rising awareness of environmental issues. Overall, the solar photovoltaic wafer market is poised for significant growth, offering a sustainable solution to the global energy challenges.

| Report Metric | Details |

| Report Name | Solar Photovoltaic Wafer - Market |

| Forecasted market size in 2030 | US$ 8344.1 million |

| CAGR | 14.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | GCL-Poly Energy Holdings Limited, Zhonghuan Semiconductor Corporation, Xi'an LONGi Silicon Materials Corp, Sino-American Silicon Products, JA Solar Inc, Jinko Solar, Canadian Solar, Solargiga Energy, HongYuan New Material (Baotou) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |