What is Global Shrink Sleeve Labeling and Tamper Evident Band Systems Market?

The global Shrink Sleeve Labeling and Tamper Evident Band Systems market is a specialized segment within the packaging industry that focuses on providing secure and visually appealing labeling solutions. Shrink sleeve labels are made from materials like PVC, PETG, and OPS, which shrink tightly around the contours of a product when heat is applied. This type of labeling is popular because it offers 360-degree coverage, allowing for more creative and informative designs. Tamper-evident band systems, on the other hand, are designed to provide an additional layer of security by indicating whether a product has been opened or tampered with. These systems are crucial for maintaining product integrity and consumer trust, especially in industries where safety and authenticity are paramount. The market for these systems is driven by the increasing demand for secure packaging solutions across various sectors, including food and beverage, pharmaceuticals, and personal care products. As consumer awareness about product safety continues to grow, the adoption of shrink sleeve labeling and tamper-evident band systems is expected to rise, making it a vital component of modern packaging strategies.

Semi-automatic Type, Fully Automatic Type in the Global Shrink Sleeve Labeling and Tamper Evident Band Systems Market:

In the realm of Global Shrink Sleeve Labeling and Tamper Evident Band Systems, there are two primary types of machinery: semi-automatic and fully automatic systems. Semi-automatic systems require some level of human intervention for operations such as feeding the labels or bands into the machine and aligning the products. These systems are generally more affordable and are suitable for small to medium-sized businesses that have lower production volumes. They offer flexibility and ease of use, making them ideal for companies that need to frequently change their labeling designs or product lines. On the other hand, fully automatic systems are designed for high-speed, high-volume production environments. These machines can handle the entire labeling process autonomously, from feeding the labels to applying them and even performing quality checks. Fully automatic systems are equipped with advanced features like sensors and programmable logic controllers (PLCs) that ensure precision and efficiency. They are often used by large-scale manufacturers who need to maintain consistent quality and meet high production demands. Both types of systems have their own set of advantages and are chosen based on the specific needs and scale of the business. While semi-automatic systems offer cost-effectiveness and flexibility, fully automatic systems provide speed and efficiency, making them suitable for different market segments.

Food and Beverage, Medicine, Cosmetics and Personal Care, Other in the Global Shrink Sleeve Labeling and Tamper Evident Band Systems Market:

The usage of Global Shrink Sleeve Labeling and Tamper Evident Band Systems spans across various industries, each with its unique requirements and benefits. In the food and beverage sector, these systems are used to provide attractive and informative labels that can withstand various environmental conditions such as moisture and temperature changes. The 360-degree coverage offered by shrink sleeve labels allows for more detailed product information and branding, which can enhance consumer appeal. Tamper-evident bands are particularly crucial in this industry to ensure product safety and integrity, preventing contamination and ensuring that the product reaches the consumer in its intended state. In the pharmaceutical industry, the importance of tamper-evident band systems cannot be overstated. These systems help in maintaining the authenticity and safety of medicinal products, which is critical for consumer health. Shrink sleeve labels in this sector often include important information such as dosage instructions, ingredients, and expiration dates, making them an essential part of the packaging. The cosmetics and personal care industry also benefits significantly from these labeling systems. Shrink sleeve labels provide a sleek and modern look that can enhance the visual appeal of products, while tamper-evident bands ensure that the products have not been tampered with, maintaining consumer trust. Other industries, such as household goods and chemicals, also utilize these systems to provide secure and informative packaging solutions. The versatility and effectiveness of shrink sleeve labeling and tamper-evident band systems make them indispensable across various sectors, contributing to their growing adoption worldwide.

Global Shrink Sleeve Labeling and Tamper Evident Band Systems Market Outlook:

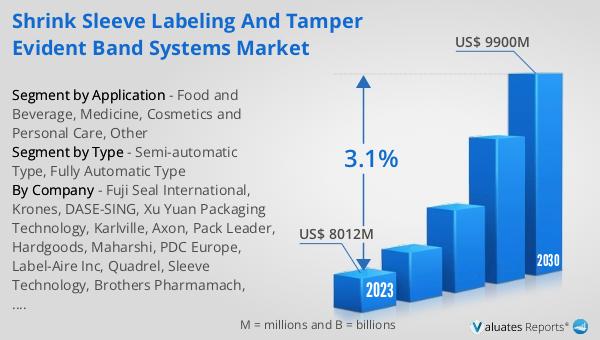

The global market for Shrink Sleeve Labeling and Tamper Evident Band Systems was valued at approximately USD 8,012 million in 2023. Projections indicate that this market is expected to grow, reaching an estimated value of USD 9,900 million by the year 2030. This growth is anticipated to occur at a compound annual growth rate (CAGR) of 3.1% during the forecast period from 2024 to 2030. This upward trend reflects the increasing demand for secure and visually appealing packaging solutions across various industries. As consumer awareness about product safety and authenticity continues to rise, the adoption of these advanced labeling systems is expected to grow, driving the market forward.

| Report Metric | Details |

| Report Name | Shrink Sleeve Labeling and Tamper Evident Band Systems Market |

| Accounted market size in 2023 | US$ 8012 million |

| Forecasted market size in 2030 | US$ 9900 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Fuji Seal International, Krones, DASE-SING, Xu Yuan Packaging Technology, Karlville, Axon, Pack Leader, Hardgoods, Maharshi, PDC Europe, Label-Aire Inc, Quadrel, Sleeve Technology, Brothers Pharmamach, Shree Bhagwati |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |