What is Global Aluminum Alloys for Automobiles Market?

The Global Aluminum Alloys for Automobiles Market refers to the worldwide industry focused on the production and application of aluminum alloys in the automotive sector. Aluminum alloys are mixtures of aluminum with other elements like copper, magnesium, and silicon, which enhance the metal's properties such as strength, durability, and resistance to corrosion. These alloys are increasingly used in the automotive industry due to their lightweight nature, which helps in improving fuel efficiency and reducing emissions. The market encompasses various types of aluminum alloys, including cast, rolled, and extruded forms, each serving different purposes in vehicle manufacturing. The demand for aluminum alloys in automobiles is driven by the need for lighter, more fuel-efficient vehicles, stringent environmental regulations, and advancements in automotive technology. This market is a critical component of the broader automotive industry, influencing the design, performance, and sustainability of modern vehicles.

Cast Aluminum Alloy, Rolled Aluminum Alloy, Extruded Aluminum Alloy in the Global Aluminum Alloys for Automobiles Market:

Cast aluminum alloy, rolled aluminum alloy, and extruded aluminum alloy are three primary types of aluminum alloys used in the global automotive market, each with distinct characteristics and applications. Cast aluminum alloys are produced by pouring molten aluminum into molds, where it solidifies into the desired shape. This type of alloy is known for its excellent fluidity, making it ideal for creating complex shapes and intricate designs. Cast aluminum alloys are commonly used in engine blocks, cylinder heads, and other components that require high strength and durability. Rolled aluminum alloys, on the other hand, are manufactured by passing aluminum through rollers to achieve the desired thickness and shape. This process enhances the metal's mechanical properties, such as tensile strength and hardness, making it suitable for applications that require high structural integrity. Rolled aluminum alloys are often used in body panels, hoods, and other exterior parts of vehicles. Extruded aluminum alloys are produced by forcing aluminum through a die to create long, continuous shapes with uniform cross-sections. This method allows for the production of lightweight, yet strong components that can be easily customized to meet specific design requirements. Extruded aluminum alloys are commonly used in chassis, suspension systems, and other structural parts of automobiles. Each type of aluminum alloy offers unique benefits and plays a crucial role in enhancing the performance, safety, and efficiency of modern vehicles.

Powertrain, Chassis and Suspension, Car Body, Others in the Global Aluminum Alloys for Automobiles Market:

The usage of global aluminum alloys in automobiles spans several critical areas, including powertrain, chassis and suspension, car body, and others. In the powertrain, aluminum alloys are used to manufacture engine blocks, cylinder heads, and transmission cases. The lightweight nature of aluminum helps reduce the overall weight of the powertrain, leading to improved fuel efficiency and better performance. Additionally, aluminum's excellent thermal conductivity aids in better heat dissipation, enhancing the engine's cooling efficiency and longevity. In the chassis and suspension systems, aluminum alloys are employed to create components such as control arms, subframes, and shock absorbers. The use of aluminum in these parts helps reduce the vehicle's unsprung weight, which improves handling, ride comfort, and overall driving dynamics. Moreover, aluminum's high strength-to-weight ratio ensures that these components can withstand the stresses and strains of everyday driving while contributing to the vehicle's overall structural integrity. For the car body, aluminum alloys are used in the construction of body panels, doors, hoods, and trunk lids. The lightweight properties of aluminum help reduce the vehicle's overall weight, leading to better fuel efficiency and lower emissions. Additionally, aluminum's resistance to corrosion ensures that the car body remains in good condition for a longer period, reducing maintenance costs and enhancing the vehicle's resale value. Other areas where aluminum alloys are used in automobiles include wheels, brake components, and heat exchangers. Aluminum wheels are popular due to their lightweight and stylish designs, which improve the vehicle's aesthetics and performance. Brake components made from aluminum alloys offer better heat dissipation, reducing the risk of brake fade and improving braking performance. Heat exchangers, such as radiators and intercoolers, benefit from aluminum's excellent thermal conductivity, ensuring efficient cooling and optimal engine performance. Overall, the use of aluminum alloys in various areas of automobiles contributes to improved performance, fuel efficiency, safety, and sustainability.

Global Aluminum Alloys for Automobiles Market Outlook:

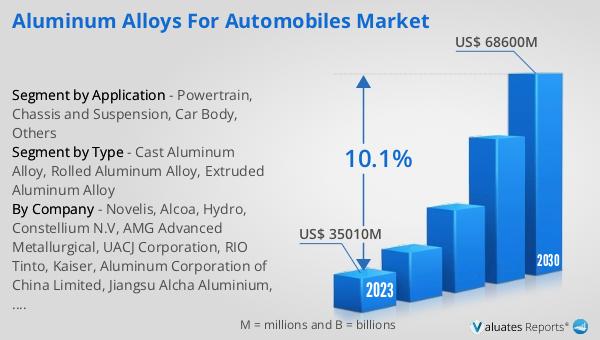

The global market for aluminum alloys in automobiles was valued at $35,010 million in 2023 and is projected to reach $68,600 million by 2030, reflecting a compound annual growth rate (CAGR) of 10.1% during the forecast period from 2024 to 2030. This significant growth underscores the increasing demand for lightweight, fuel-efficient vehicles and the automotive industry's shift towards more sustainable materials. Aluminum alloys play a crucial role in this transition, offering a combination of strength, durability, and lightweight properties that enhance vehicle performance and reduce emissions. The market's expansion is driven by advancements in automotive technology, stringent environmental regulations, and the growing consumer preference for eco-friendly vehicles. As automakers continue to innovate and adopt new materials, the demand for aluminum alloys is expected to rise, further solidifying their importance in the global automotive market.

| Report Metric | Details |

| Report Name | Aluminum Alloys for Automobiles Market |

| Accounted market size in 2023 | US$ 35010 million |

| Forecasted market size in 2030 | US$ 68600 million |

| CAGR | 10.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Novelis, Alcoa, Hydro, Constellium N.V, AMG Advanced Metallurgical, UACJ Corporation, RIO Tinto, Kaiser, Aluminum Corporation of China Limited, Jiangsu Alcha Aluminium, Shandong Nanshan Aluminium, Mingtai Al, Apalt |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |