What is Global Water-resistant Grease Market?

The Global Water-resistant Grease Market is a specialized segment within the broader lubricants industry, focusing on greases that are specifically formulated to resist water washout and maintain performance in wet or humid environments. These greases are essential in applications where exposure to water, whether through direct contact or high humidity, can compromise the effectiveness of standard lubricants. Water-resistant greases are designed to provide superior protection against rust and corrosion, ensuring the longevity and reliability of machinery and equipment. They are used across various industries, including automotive, marine, food processing, and manufacturing, where equipment is frequently exposed to water or moisture. The demand for these greases is driven by the need for enhanced equipment performance and reduced maintenance costs, as they help prevent downtime and extend the life of machinery. As industries continue to seek more efficient and durable solutions, the market for water-resistant greases is expected to grow, driven by technological advancements and the development of new formulations that offer improved performance characteristics. The market's growth is also supported by increasing industrialization and the expansion of sectors that require robust lubrication solutions.

Synthetic Hydrocarbon-based, Silicone Oil-based, Polyether-based, Mineral Oil-based in the Global Water-resistant Grease Market:

In the Global Water-resistant Grease Market, different types of base oils are used to formulate greases, each offering unique properties and benefits. Synthetic hydrocarbon-based greases are known for their excellent thermal stability and low-temperature performance. These greases are often used in applications where extreme temperatures are a concern, as they maintain their lubricating properties across a wide temperature range. They also offer good resistance to oxidation and degradation, making them suitable for long-term use in demanding environments. Silicone oil-based greases, on the other hand, are prized for their exceptional water resistance and dielectric properties. They are often used in electrical applications and in environments where exposure to water or chemicals is a concern. Silicone greases are also known for their stability over a wide temperature range, although they may not offer the same load-carrying capacity as other types of greases. Polyether-based greases are a newer addition to the market, offering excellent water resistance and compatibility with a wide range of materials. These greases are often used in applications where compatibility with plastics and elastomers is important, such as in the automotive and aerospace industries. They also offer good thermal stability and resistance to oxidation, making them suitable for high-temperature applications. Mineral oil-based greases are the most traditional type of grease, offering a good balance of performance and cost. They are widely used in general-purpose applications and are known for their good lubricating properties and ease of formulation. However, they may not offer the same level of performance as synthetic or silicone-based greases in extreme conditions. Each type of base oil offers distinct advantages and is chosen based on the specific requirements of the application, such as temperature range, load-carrying capacity, and environmental conditions. The choice of base oil is a critical factor in the formulation of water-resistant greases, as it determines the grease's overall performance and suitability for different applications. As the market continues to evolve, manufacturers are investing in research and development to create new formulations that offer improved performance and meet the changing needs of industries.

Marine Shafting, Paper Machine Drying Cylinders, Food Processing Equipment, Hydropower Equipment, Others in the Global Water-resistant Grease Market:

The Global Water-resistant Grease Market finds extensive usage across various sectors, each with unique requirements and challenges. In marine shafting, water-resistant greases are crucial for ensuring the smooth operation of propeller shafts and other components exposed to seawater. These greases provide excellent protection against corrosion and wear, helping to extend the life of marine equipment and reduce maintenance costs. In paper machine drying cylinders, water-resistant greases are used to lubricate bearings and other components that are exposed to high humidity and temperature. These greases help prevent rust and corrosion, ensuring the efficient operation of paper machines and minimizing downtime. In the food processing industry, water-resistant greases are used in equipment that is frequently washed down or exposed to moisture. These greases are formulated to be food-safe, ensuring that they do not contaminate food products while providing effective lubrication and protection against corrosion. In hydropower equipment, water-resistant greases are used to lubricate turbines and other components that are exposed to water. These greases help ensure the efficient operation of hydropower plants, reducing the risk of equipment failure and downtime. Other applications of water-resistant greases include construction equipment, where they are used to lubricate components exposed to dirt and moisture, and automotive applications, where they are used in wheel bearings and other components exposed to water and road spray. The versatility and effectiveness of water-resistant greases make them an essential component in a wide range of industries, helping to improve equipment performance and reduce maintenance costs. As industries continue to seek more efficient and durable solutions, the demand for water-resistant greases is expected to grow, driven by the need for enhanced equipment performance and reduced maintenance costs.

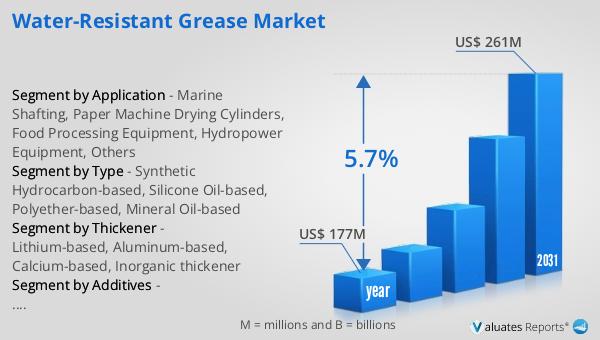

Global Water-resistant Grease Market Outlook:

The global market for water-resistant grease was valued at approximately $177 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $261 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.7% over the forecast period. The increasing demand for water-resistant grease is driven by its essential role in various industries, where it provides critical protection against water-induced wear and corrosion. As industries continue to evolve and expand, the need for reliable and efficient lubrication solutions becomes more pronounced. Water-resistant greases are particularly valued for their ability to maintain performance in challenging environments, where exposure to water and moisture is a constant concern. This market growth is also supported by advancements in grease formulations, which offer improved performance characteristics and meet the specific needs of different applications. As a result, manufacturers are investing in research and development to create new and innovative products that cater to the diverse requirements of industries. The projected growth of the water-resistant grease market reflects the increasing importance of these products in ensuring the longevity and reliability of machinery and equipment across various sectors.

| Report Metric | Details |

| Report Name | Water-resistant Grease Market |

| Accounted market size in year | US$ 177 million |

| Forecasted market size in 2031 | US$ 261 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Thickener |

|

| Segment by Additives |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Klüber Lubrication, Fuchs Petrolub, Shell, Sinopec, JAX, 3M, TotalEnergies, ExxonMobil, KYODO YUSHI, Fuchs, THK, Henkel, BASF, Essence, Chevron, Techoel |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |