What is Global Engineered Abrasive Grain Market?

The Global Engineered Abrasive Grain Market is a specialized segment within the broader abrasives industry, focusing on the production and distribution of engineered abrasive grains. These grains are meticulously designed and manufactured to meet specific industrial requirements, offering enhanced performance compared to natural or conventional abrasives. Engineered abrasive grains are used in various applications, including grinding, cutting, polishing, and surface finishing, across multiple industries such as automotive, aerospace, metal fabrication, and electronics. The market is driven by the increasing demand for high-precision and efficient abrasive solutions that can improve productivity and reduce operational costs. Technological advancements in manufacturing processes and the development of new materials have further propelled the growth of this market. Additionally, the rising focus on sustainability and the need for eco-friendly abrasive solutions have led to innovations in the production of engineered abrasive grains. As industries continue to evolve and demand more sophisticated abrasive solutions, the Global Engineered Abrasive Grain Market is expected to expand, offering new opportunities for manufacturers and suppliers. The market's growth is also supported by the increasing adoption of automation and advanced machinery in various sectors, which require high-quality abrasive materials for optimal performance.

in the Global Engineered Abrasive Grain Market:

The Global Engineered Abrasive Grain Market comprises various types of abrasive grains, each designed to meet the specific needs of different industries and applications. One of the most common types is aluminum oxide, known for its durability and versatility. It is widely used in metal fabrication, woodworking, and general industrial applications due to its ability to cut through tough materials efficiently. Silicon carbide is another popular type, recognized for its hardness and sharpness, making it ideal for applications requiring high precision and fine finishes, such as in the electronics and automotive industries. Ceramic abrasive grains are engineered for high-performance applications, offering superior cutting capabilities and longer lifespan compared to traditional abrasives. These grains are often used in heavy-duty metal fabrication and aerospace manufacturing, where durability and efficiency are paramount. Zirconia alumina is another type of engineered abrasive grain, known for its toughness and self-sharpening properties. It is commonly used in applications involving heavy grinding and cutting, such as in the steel and foundry industries. Each type of engineered abrasive grain is designed to offer specific benefits, such as increased cutting speed, improved surface finish, and longer tool life, making them suitable for a wide range of industrial applications. The choice of abrasive grain type depends on factors such as the material being processed, the desired finish, and the specific requirements of the application. As industries continue to demand more efficient and effective abrasive solutions, manufacturers are investing in research and development to create new and improved types of engineered abrasive grains. This ongoing innovation is driving the growth of the Global Engineered Abrasive Grain Market, providing industries with the tools they need to enhance productivity and achieve superior results. The market's expansion is also fueled by the increasing adoption of advanced manufacturing technologies, which require high-quality abrasive materials to operate at peak efficiency. As a result, the demand for engineered abrasive grains is expected to continue rising, offering new opportunities for manufacturers and suppliers in this dynamic market.

Heavy Duty Metal Fabrication, Precision Grinding and Finishing, Automotive and Aerospace Manufacturing, General Industrial and Fabrication, Others in the Global Engineered Abrasive Grain Market:

The usage of Global Engineered Abrasive Grain Market spans across various industries, each with its unique requirements and applications. In heavy-duty metal fabrication, engineered abrasive grains are essential for cutting, grinding, and shaping metal components. These grains offer superior cutting capabilities and durability, allowing manufacturers to achieve precise and efficient results. The high-performance characteristics of engineered abrasive grains make them ideal for use in demanding applications, such as in the construction of large metal structures and machinery. In precision grinding and finishing, engineered abrasive grains are used to achieve fine surface finishes and tight tolerances. These grains are designed to provide consistent performance and long tool life, making them suitable for applications in the automotive and aerospace industries, where precision and quality are critical. In automotive and aerospace manufacturing, engineered abrasive grains are used in various processes, including surface preparation, deburring, and polishing. The ability of these grains to deliver high-quality finishes and improve productivity makes them an essential component in the production of vehicles and aircraft. In general industrial and fabrication applications, engineered abrasive grains are used for a wide range of tasks, from cutting and grinding to polishing and finishing. The versatility and efficiency of these grains make them a valuable tool for manufacturers in various sectors, including electronics, woodworking, and metalworking. Other applications of engineered abrasive grains include the production of consumer goods, medical devices, and renewable energy components. The demand for high-performance abrasive solutions in these areas is driving the growth of the Global Engineered Abrasive Grain Market, as industries seek to improve efficiency and reduce costs. As the market continues to evolve, manufacturers are developing new and innovative abrasive grains to meet the changing needs of their customers, ensuring that they remain competitive in this dynamic industry.

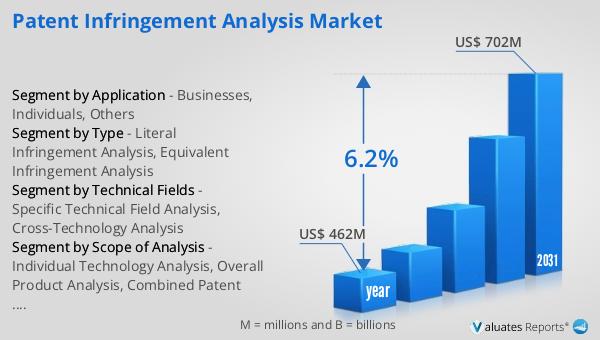

Global Engineered Abrasive Grain Market Outlook:

The global market for Engineered Abrasive Grain was valued at $223 million in 2024 and is anticipated to grow to a revised size of $301 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.5% over the forecast period. This growth trajectory underscores the increasing demand for high-performance abrasive solutions across various industries. The market's expansion is driven by the need for more efficient and effective abrasive materials that can enhance productivity and reduce operational costs. As industries continue to adopt advanced manufacturing technologies and automation, the demand for engineered abrasive grains is expected to rise, offering new opportunities for manufacturers and suppliers. The market's growth is also supported by the rising focus on sustainability and the development of eco-friendly abrasive solutions. As a result, the Global Engineered Abrasive Grain Market is poised for significant growth, providing industries with the tools they need to achieve superior results and remain competitive in an ever-evolving landscape. The increasing adoption of engineered abrasive grains in various applications, such as metal fabrication, automotive manufacturing, and precision grinding, is further fueling the market's expansion, highlighting the importance of these materials in modern industrial processes.

| Report Metric | Details |

| Report Name | Engineered Abrasive Grain Market |

| Accounted market size in year | US$ 223 million |

| Forecasted market size in 2031 | US$ 301 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Technology Route |

|

| Segment by Grain Form Factor |

|

| Segment by FEPA Size Class |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Saint-Gobain Abrasive Grains, Washington Mills, 3M Abrasive Systems, CUMI Electro Minerals, Fujimi Incorporated, Zhengzhou YUFA Abrasive Group, Zhengzhou Haixu Abrasives, Kumthai Abrasives, Henan Sicheng Abrasives, Micro Abrasives Corp., NICE Abrasive, DOMILL Abrasive, RIKEN RMC, DH-C Ceramics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |