What is Global Microcomputer-Controlled Ring Stiffness Testing Machine Market?

The Global Microcomputer-Controlled Ring Stiffness Testing Machine Market refers to the industry focused on the production and distribution of specialized testing machines that measure the stiffness of rings, typically used in pipes and other cylindrical structures. These machines are equipped with microcomputers that control the testing process, ensuring precision and accuracy in measuring the stiffness of materials. This market is driven by the increasing demand for quality assurance and material testing in various industries, such as construction, manufacturing, and infrastructure development. The machines are essential for ensuring that materials meet specific standards and can withstand external pressures without deforming. As industries continue to prioritize safety and durability, the demand for these testing machines is expected to grow. The market encompasses a range of products, from basic models to advanced systems with enhanced features, catering to different industry needs and budgets. The growth of this market is also influenced by technological advancements, which have led to the development of more efficient and user-friendly machines. Overall, the Global Microcomputer-Controlled Ring Stiffness Testing Machine Market plays a crucial role in maintaining the integrity and reliability of materials used in various applications.

Vertical, Horizontal in the Global Microcomputer-Controlled Ring Stiffness Testing Machine Market:

In the Global Microcomputer-Controlled Ring Stiffness Testing Machine Market, the terms "vertical" and "horizontal" refer to the orientation and application of the testing machines. Vertical machines are designed to test the stiffness of rings in an upright position. These machines are often used when the material being tested is long or when the testing environment requires a smaller footprint. Vertical machines are advantageous in scenarios where space is limited, as they can be placed in compact areas without compromising on performance. They are commonly used in industries where the testing of pipes and tubes is frequent, such as in construction and plumbing. The vertical orientation allows for easy loading and unloading of test samples, making the process more efficient. On the other hand, horizontal machines are designed to test rings laid flat. This orientation is beneficial when dealing with larger or heavier samples that are difficult to position vertically. Horizontal machines are often used in industries where the testing of large-diameter pipes is necessary, such as in oil and gas or water supply systems. The horizontal setup provides stability and ease of access, allowing for precise measurements even with bulky materials. Both vertical and horizontal machines are equipped with microcomputers that control the testing process, ensuring accurate and reliable results. The choice between vertical and horizontal machines depends on the specific requirements of the testing application, including the size and weight of the samples, the available space, and the desired level of automation. In some cases, industries may opt for a combination of both types to accommodate a wider range of testing needs. The versatility of these machines makes them indispensable in quality control processes across various sectors. As industries continue to evolve and demand more sophisticated testing solutions, manufacturers are developing machines that offer greater flexibility and enhanced features. This includes the integration of advanced software for data analysis and reporting, as well as the ability to perform multiple tests simultaneously. The ongoing innovation in this market ensures that both vertical and horizontal machines remain relevant and capable of meeting the diverse needs of modern industries. Overall, the Global Microcomputer-Controlled Ring Stiffness Testing Machine Market is characterized by its adaptability and commitment to providing reliable testing solutions that enhance material quality and safety.

Chemical Industry, Aerospace, Mechanical Manufacturing, Electric Power, Other in the Global Microcomputer-Controlled Ring Stiffness Testing Machine Market:

The Global Microcomputer-Controlled Ring Stiffness Testing Machine Market finds extensive usage across various industries, including the chemical industry, aerospace, mechanical manufacturing, electric power, and others. In the chemical industry, these machines are crucial for testing the stiffness of pipes and containers used to transport and store chemicals. Ensuring that these materials can withstand internal and external pressures is vital for preventing leaks and maintaining safety standards. The precision offered by microcomputer-controlled machines allows for accurate assessments, ensuring that materials meet the stringent requirements of chemical processing environments. In the aerospace industry, the need for lightweight yet durable materials is paramount. Ring stiffness testing machines are used to evaluate the structural integrity of components such as ducts and conduits, which are essential for maintaining the performance and safety of aircraft. The ability to test materials under simulated conditions helps manufacturers develop components that can endure the stresses of flight. In mechanical manufacturing, these machines play a key role in quality control processes. They are used to test the stiffness of various components, ensuring that they meet design specifications and can perform reliably under operational conditions. This is particularly important in industries where precision and durability are critical, such as automotive and machinery manufacturing. In the electric power sector, ring stiffness testing machines are used to assess the integrity of cables and conduits that house electrical wiring. Ensuring that these materials can withstand environmental stresses is crucial for maintaining the reliability and safety of power distribution systems. The machines provide valuable data that helps manufacturers improve the design and performance of electrical components. Beyond these industries, the versatility of microcomputer-controlled ring stiffness testing machines makes them applicable in a wide range of other sectors. They are used in infrastructure projects to test the materials used in pipelines and drainage systems, ensuring that they can withstand the pressures of use and environmental factors. The machines are also employed in research and development settings, where they aid in the development of new materials and products. Overall, the Global Microcomputer-Controlled Ring Stiffness Testing Machine Market plays a vital role in ensuring the quality and safety of materials used across diverse industries. The precision and reliability offered by these machines make them indispensable tools in modern manufacturing and quality assurance processes.

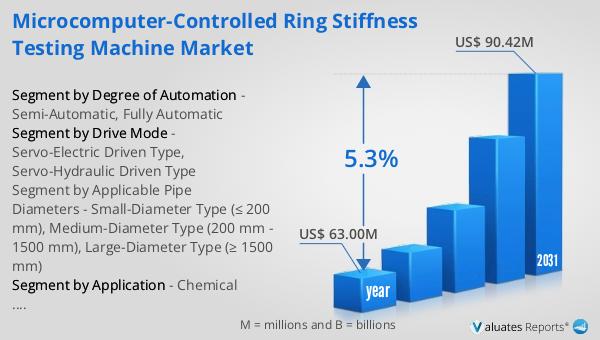

Global Microcomputer-Controlled Ring Stiffness Testing Machine Market Outlook:

The global market for Microcomputer-Controlled Ring Stiffness Testing Machines was valued at approximately $63 million in 2024. It is anticipated to expand to a revised size of around $90.42 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.3% over the forecast period. This growth trajectory underscores the increasing demand for these specialized testing machines across various industries. The market's expansion is driven by the need for precise and reliable testing solutions that ensure the quality and durability of materials used in construction, manufacturing, and infrastructure projects. As industries continue to prioritize safety and performance, the adoption of advanced testing technologies is expected to rise. The integration of microcomputers in these machines enhances their accuracy and efficiency, making them essential tools for quality assurance processes. The projected growth also highlights the ongoing innovation within the market, with manufacturers developing machines that offer greater flexibility and advanced features. This includes the incorporation of sophisticated software for data analysis and reporting, as well as the ability to perform multiple tests simultaneously. The market's positive outlook reflects the critical role that microcomputer-controlled ring stiffness testing machines play in maintaining the integrity and reliability of materials used in various applications. As industries evolve and demand more sophisticated testing solutions, the market is poised for continued growth and development.

| Report Metric | Details |

| Report Name | Microcomputer-Controlled Ring Stiffness Testing Machine Market |

| Accounted market size in year | US$ 63.00 million |

| Forecasted market size in 2031 | US$ 90.42 million |

| CAGR | 5.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Degree of Automation |

|

| Segment by Applicable Pipe Diameters |

|

| Segment by Drive Mode |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Instron, ZwickRoell, MTS, Jinan Tianchen Testing Machine Manufacturing, Jinan Kesheng Testing Equipment, Sinter, WANCE, LSI, Jinan Sida Testing Technology, Jinan Xinbiao Automation Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |