What is Global Hex Flange Bolts Market?

The Global Hex Flange Bolts Market is a significant segment within the fasteners industry, characterized by its specialized design and diverse applications. Hex flange bolts are unique due to their built-in washer-like flange, which provides a larger surface area for distributing the load. This design feature enhances their ability to secure materials tightly, reducing the risk of loosening under vibration or pressure. The market for these bolts is driven by their widespread use in various industries, including automotive, construction, and machinery, where reliability and durability are paramount. As industries continue to evolve and demand more efficient and robust fastening solutions, the global hex flange bolts market is poised for growth. The market's expansion is further fueled by technological advancements in manufacturing processes, which have improved the quality and performance of these bolts. Additionally, the increasing focus on infrastructure development and industrialization in emerging economies is contributing to the rising demand for hex flange bolts. As a result, manufacturers are investing in research and development to innovate and meet the specific needs of different sectors, ensuring that hex flange bolts remain a vital component in modern engineering and construction projects.

Wide Hex Flange Bolts, Narrow Hex Flange Bolts in the Global Hex Flange Bolts Market:

Wide Hex Flange Bolts and Narrow Hex Flange Bolts are two primary types of hex flange bolts that cater to different needs within the Global Hex Flange Bolts Market. Wide hex flange bolts are designed with a broader flange, which provides a larger surface area for load distribution. This makes them particularly suitable for applications where the bolt needs to secure materials with a greater degree of stability and resistance to loosening. The wider flange also helps in reducing the pressure on the material being fastened, which can be crucial in applications involving softer materials or where the integrity of the surface finish is important. On the other hand, narrow hex flange bolts have a smaller flange, which allows them to be used in applications where space is limited or where a more compact fastening solution is required. Despite their smaller flange, these bolts still offer a significant advantage in terms of load distribution compared to standard hex bolts without a flange. The choice between wide and narrow hex flange bolts often depends on the specific requirements of the application, including the type of materials being fastened, the environmental conditions, and the mechanical stresses involved. In the automotive industry, for example, wide hex flange bolts might be used in engine assemblies where high vibration and thermal expansion are factors, while narrow hex flange bolts could be employed in areas with limited space, such as electronic components or interior fittings. Similarly, in the construction industry, wide hex flange bolts might be preferred for securing structural elements, while narrow hex flange bolts could be used in more confined spaces or for aesthetic reasons. The versatility of hex flange bolts, whether wide or narrow, makes them an essential component in many industries, providing reliable and efficient fastening solutions that meet the diverse needs of modern engineering and manufacturing. As the demand for more specialized and high-performance fasteners continues to grow, manufacturers are likely to focus on developing new materials and coatings that enhance the performance of both wide and narrow hex flange bolts, ensuring they remain a critical part of the global fasteners market.

Automotive, Marine, Aerospace & Defense, Construction, Industrial Machinery, Electronics, Others in the Global Hex Flange Bolts Market:

The Global Hex Flange Bolts Market finds extensive usage across various sectors, each with its unique requirements and challenges. In the automotive industry, hex flange bolts are indispensable due to their ability to withstand high levels of vibration and thermal expansion. They are commonly used in engine assemblies, chassis, and other critical components where secure fastening is crucial for safety and performance. The marine industry also relies heavily on hex flange bolts, particularly for applications that require resistance to corrosion and exposure to harsh environmental conditions. These bolts are used in the construction of ships, boats, and offshore structures, where durability and reliability are paramount. In the aerospace and defense sectors, hex flange bolts are used in aircraft and military vehicles, where they must meet stringent standards for strength and performance. The construction industry benefits from hex flange bolts in the assembly of steel structures, bridges, and buildings, where they provide the necessary strength and stability to withstand various loads and stresses. Industrial machinery also utilizes hex flange bolts for assembling equipment and machinery that operate under high stress and vibration. In the electronics sector, these bolts are used in the assembly of electronic devices and components, where precision and reliability are essential. Other industries, such as renewable energy and telecommunications, also use hex flange bolts for various applications, highlighting their versatility and importance in modern engineering and manufacturing. As industries continue to evolve and demand more efficient and reliable fastening solutions, the Global Hex Flange Bolts Market is expected to grow, driven by technological advancements and the increasing focus on infrastructure development and industrialization.

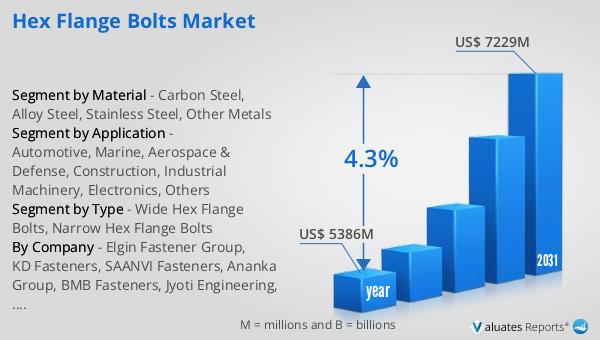

Global Hex Flange Bolts Market Outlook:

The global market for Hex Flange Bolts was valued at $5,386 million in 2024 and is anticipated to expand to a revised size of $7,229 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.3% over the forecast period. This growth trajectory underscores the increasing demand for hex flange bolts across various industries, driven by their unique design and functionality. The built-in flange of these bolts provides a larger surface area for load distribution, making them ideal for applications that require secure and stable fastening. As industries such as automotive, construction, and aerospace continue to evolve, the need for reliable and efficient fastening solutions is becoming more critical. The market's expansion is also supported by technological advancements in manufacturing processes, which have enhanced the quality and performance of hex flange bolts. Additionally, the growing focus on infrastructure development and industrialization in emerging economies is contributing to the rising demand for these bolts. As a result, manufacturers are investing in research and development to innovate and meet the specific needs of different sectors, ensuring that hex flange bolts remain a vital component in modern engineering and construction projects. The projected growth of the global hex flange bolts market highlights the importance of these fasteners in supporting the development and advancement of various industries worldwide.

| Report Metric | Details |

| Report Name | Hex Flange Bolts Market |

| Accounted market size in year | US$ 5386 million |

| Forecasted market size in 2031 | US$ 7229 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Material |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Elgin Fastener Group, KD Fasteners, SAANVI Fasteners, Ananka Group, BMB Fasteners, Jyoti Engineering, Varmora Forge, Jiashan Yijin Hardware, Shanghai Jianxin Hardware, Ningbo Teng Qi Fasteners, Tianjin Xinruifeng Technology, Hangzhou Lizhan Hardware, Ningbo OuKaiLuo Hardware, Shanghai Jingyang Fastener |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |