What is Global Low-Sludge Phosphating Solution Market?

The Global Low-Sludge Phosphating Solution Market refers to the industry focused on the production and distribution of phosphating solutions that generate minimal sludge during the metal treatment process. Phosphating is a chemical treatment used to prepare metal surfaces for painting or coating, enhancing corrosion resistance and paint adhesion. Traditional phosphating processes often produce significant amounts of sludge, which can be environmentally harmful and costly to manage. Low-sludge phosphating solutions are designed to minimize this waste, making them more environmentally friendly and cost-effective. These solutions are particularly important in industries where metal treatment is a critical step, such as automotive, aerospace, and manufacturing. By reducing sludge production, these solutions help companies comply with environmental regulations and reduce waste disposal costs. The market for low-sludge phosphating solutions is driven by increasing environmental awareness, stringent regulations, and the need for efficient and sustainable manufacturing processes. As industries continue to seek ways to reduce their environmental footprint and improve operational efficiency, the demand for low-sludge phosphating solutions is expected to grow. This market encompasses various types of phosphating solutions, each tailored to specific applications and metal types, ensuring optimal performance and minimal environmental impact.

Zinc-based, Iron-based, Zinc-iron-based, Manganese-based, Zinc-calcium-based, Zinc-manganese-based, Other in the Global Low-Sludge Phosphating Solution Market:

In the Global Low-Sludge Phosphating Solution Market, various types of phosphating solutions are utilized, each with unique properties and applications. Zinc-based phosphating solutions are widely used due to their excellent corrosion resistance and paint adhesion properties. These solutions form a crystalline coating on metal surfaces, providing a robust base for subsequent painting or coating processes. Iron-based phosphating solutions, on the other hand, are often used for lighter applications where corrosion resistance is less critical. They are typically employed in situations where cost-effectiveness is a priority, as they are generally less expensive than zinc-based solutions. Zinc-iron-based phosphating solutions combine the benefits of both zinc and iron, offering a balance between cost and performance. These solutions are particularly useful in applications where moderate corrosion resistance is required. Manganese-based phosphating solutions are known for their superior wear resistance and are often used in heavy-duty applications such as automotive and machinery parts. These solutions provide a thick, durable coating that can withstand harsh conditions. Zinc-calcium-based phosphating solutions are less common but offer unique benefits, such as improved coating uniformity and reduced sludge formation. They are often used in specialized applications where these properties are particularly advantageous. Zinc-manganese-based solutions combine the benefits of both zinc and manganese, providing excellent corrosion and wear resistance. These solutions are ideal for applications where both properties are critical. Other types of phosphating solutions in the market may include specialized formulations designed for specific metals or applications, offering tailored performance characteristics. Each type of phosphating solution in the Global Low-Sludge Phosphating Solution Market is designed to meet the specific needs of different industries and applications, ensuring optimal performance and minimal environmental impact.

Automobiles, Shipbuilding, Aerospace, Machinery, Home Appliances, Other in the Global Low-Sludge Phosphating Solution Market:

The Global Low-Sludge Phosphating Solution Market finds extensive usage across various industries, each benefiting from the unique properties of these solutions. In the automobile industry, low-sludge phosphating solutions are crucial for preparing metal surfaces before painting. They enhance paint adhesion and corrosion resistance, ensuring the longevity and durability of vehicles. The reduced sludge production also aligns with the industry's push towards more sustainable manufacturing practices. In shipbuilding, these solutions are used to treat metal surfaces exposed to harsh marine environments. The enhanced corrosion resistance provided by phosphating solutions is vital for the longevity of ships and marine structures. In the aerospace industry, where precision and reliability are paramount, low-sludge phosphating solutions are used to treat aircraft components, ensuring they can withstand extreme conditions while maintaining structural integrity. The machinery industry also benefits from these solutions, as they provide a durable base for coatings on heavy machinery and equipment, enhancing their lifespan and performance. In the home appliances sector, phosphating solutions are used to treat metal parts, ensuring they are resistant to corrosion and wear, which is essential for the longevity and reliability of appliances. Other industries, such as construction and electronics, also utilize low-sludge phosphating solutions to enhance the performance and durability of metal components. The versatility and effectiveness of these solutions make them an essential part of modern manufacturing processes across various sectors.

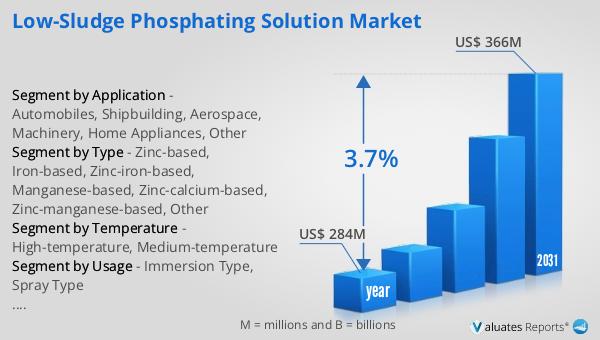

Global Low-Sludge Phosphating Solution Market Outlook:

The global market for Low-Sludge Phosphating Solution was valued at $284 million in 2024 and is anticipated to expand to a revised size of $366 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.7% during the forecast period. This growth is driven by increasing demand for environmentally friendly and cost-effective metal treatment solutions across various industries. As companies strive to reduce their environmental impact and comply with stringent regulations, the adoption of low-sludge phosphating solutions is expected to rise. These solutions offer significant advantages over traditional phosphating processes, including reduced waste production and improved operational efficiency. The market's growth is also supported by advancements in phosphating technology, which continue to enhance the performance and sustainability of these solutions. As industries such as automotive, aerospace, and manufacturing continue to evolve, the demand for high-performance, low-sludge phosphating solutions is likely to increase, driving further market expansion. The projected growth of the Global Low-Sludge Phosphating Solution Market underscores the importance of sustainable manufacturing practices and the ongoing shift towards more environmentally friendly industrial processes.

| Report Metric | Details |

| Report Name | Low-Sludge Phosphating Solution Market |

| Accounted market size in year | US$ 284 million |

| Forecasted market size in 2031 | US$ 366 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Temperature |

|

| Segment by Usage |

|

| Segment by Channel |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Henkel, BASF, PPG, Quaker Houghton, Nihon Parkerizing, YingXing Metal Surface Treatment Materials, Guangdong Zhengliyuan New Materials Technology, Liaoning Tianlong Technology, Hubei Haili Environmental Protection, Hunan Delein New Material Technology, Shenzhen Xinchengda Technology, Qingdao Ai Dasheng Environmental Protection Technology, Tianjin Tianyixing Metal Surface Treatment Agent |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |