What is Global Nodulizer Cored Wire Market?

The Global Nodulizer Cored Wire Market is a specialized segment within the metallurgical industry, focusing on the production and distribution of cored wires used in the manufacturing of nodular cast iron. Nodulizer cored wires are essential in the process of converting flake graphite into spheroidal graphite, which significantly enhances the mechanical properties of cast iron, making it more ductile and robust. This transformation is crucial for industries that require high-strength materials, such as automotive, construction, and heavy machinery. The market for these cored wires is driven by the increasing demand for high-performance materials that can withstand extreme conditions and provide longevity and reliability. The global market is characterized by a diverse range of products, including various types of cored wires that cater to different metallurgical needs. As industries continue to evolve and demand more advanced materials, the Global Nodulizer Cored Wire Market is expected to grow, driven by technological advancements and the need for more efficient and effective manufacturing processes. This market plays a pivotal role in the broader metallurgical industry, contributing to the development of innovative materials that meet the ever-changing demands of modern engineering and manufacturing.

Silicon-Calcium Wire, Pure Calcium Wire, Carbon-Coated Wire, Other in the Global Nodulizer Cored Wire Market:

Silicon-Calcium Wire, Pure Calcium Wire, Carbon-Coated Wire, and other types of cored wires are integral components of the Global Nodulizer Cored Wire Market, each serving distinct purposes in the metallurgical processes. Silicon-Calcium Wire is primarily used for deoxidation and desulfurization in steelmaking and iron casting. It is composed of silicon and calcium, which work synergistically to improve the quality of the metal by removing impurities and enhancing its mechanical properties. The addition of silicon helps in the formation of a protective layer on the molten metal, preventing oxidation, while calcium aids in the removal of sulfur, which can cause brittleness in the final product. Pure Calcium Wire, on the other hand, is used for precise control of the chemical composition of the metal. It is particularly effective in modifying the shape and distribution of inclusions within the metal, leading to improved ductility and toughness. Pure calcium is introduced into the molten metal through cored wire technology, ensuring uniform distribution and minimizing wastage. This type of wire is essential in producing high-quality steel and cast iron with superior mechanical properties. Carbon-Coated Wire is another variant used in the nodulizing process. It is designed to introduce carbon into the molten metal, which is crucial for achieving the desired graphite structure in cast iron. The carbon coating ensures that the wire dissolves efficiently in the molten metal, providing a consistent and controlled release of carbon. This results in the formation of spheroidal graphite, which enhances the strength and ductility of the cast iron. Other types of cored wires in the market include those with additional alloying elements such as magnesium, rare earth metals, and aluminum. These wires are used for specific applications where additional properties are required, such as increased resistance to wear and corrosion. The choice of cored wire depends on the specific requirements of the metallurgical process and the desired properties of the final product. The Global Nodulizer Cored Wire Market is characterized by continuous innovation and development, with manufacturers constantly exploring new compositions and technologies to meet the evolving needs of the industry. As the demand for high-performance materials continues to grow, the market for these specialized cored wires is expected to expand, driven by advancements in manufacturing processes and the increasing complexity of modern engineering applications.

Steelmaking, Iron Casting, Other in the Global Nodulizer Cored Wire Market:

The Global Nodulizer Cored Wire Market finds extensive usage in various areas, including steelmaking, iron casting, and other metallurgical processes. In steelmaking, nodulizer cored wires are used to refine the chemical composition of the steel, enhancing its mechanical properties and ensuring uniformity in the final product. The introduction of elements such as calcium and silicon through cored wires helps in deoxidizing the molten steel, removing impurities, and improving its overall quality. This process is crucial for producing high-grade steel that meets the stringent requirements of industries such as automotive, construction, and aerospace. In iron casting, nodulizer cored wires play a vital role in transforming flake graphite into spheroidal graphite, resulting in the production of ductile iron. Ductile iron is known for its superior strength, toughness, and wear resistance, making it an ideal material for manufacturing components that require high durability and reliability. The use of cored wires in iron casting ensures precise control over the nodulizing process, leading to consistent and high-quality castings. Other applications of nodulizer cored wires include their use in the production of specialty alloys and advanced materials. These wires are used to introduce specific alloying elements into the molten metal, tailoring its properties to meet the unique requirements of various applications. For instance, the addition of rare earth metals through cored wires can enhance the corrosion resistance and thermal stability of the metal, making it suitable for use in harsh environments. The versatility and effectiveness of nodulizer cored wires make them indispensable in modern metallurgical processes, contributing to the development of innovative materials that drive technological advancements across various industries. As the demand for high-performance materials continues to rise, the Global Nodulizer Cored Wire Market is poised for growth, driven by the need for more efficient and effective manufacturing solutions.

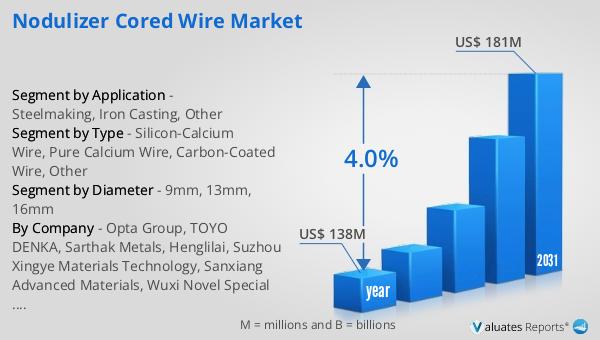

Global Nodulizer Cored Wire Market Outlook:

In 2024, the Global Nodulizer Cored Wire Market was valued at approximately $138 million. This market is anticipated to grow steadily, reaching an estimated value of $181 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.0% over the forecast period. The market's expansion is driven by the increasing demand for high-performance materials in various industries, including automotive, construction, and aerospace. As these industries continue to evolve and require more advanced materials, the need for nodulizer cored wires is expected to rise. These wires play a crucial role in enhancing the mechanical properties of metals, making them more durable and reliable for use in demanding applications. The market's growth is also supported by technological advancements in manufacturing processes, which enable the production of more efficient and effective cored wires. As manufacturers continue to innovate and develop new compositions and technologies, the Global Nodulizer Cored Wire Market is poised to expand, meeting the evolving needs of modern engineering and manufacturing. This market outlook highlights the importance of nodulizer cored wires in the broader metallurgical industry and underscores their role in driving technological advancements and supporting the development of high-performance materials.

| Report Metric | Details |

| Report Name | Nodulizer Cored Wire Market |

| Accounted market size in year | US$ 138 million |

| Forecasted market size in 2031 | US$ 181 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Diameter |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Opta Group, TOYO DENKA, Sarthak Metals, Henglilai, Suzhou Xingye Materials Technology, Sanxiang Advanced Materials, Wuxi Novel Special Metal, Anyang Changxin Special Alloy, Henan Transtrong Casting Material, Anyang Tiefa Metallurgy |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |