What is Global MIG TIG Flow Meters Market?

The Global MIG TIG Flow Meters Market is a specialized segment within the broader industrial equipment sector, focusing on devices that measure and regulate the flow of gases used in Metal Inert Gas (MIG) and Tungsten Inert Gas (TIG) welding processes. These flow meters are crucial for ensuring precision and efficiency in welding operations by controlling the flow rate of shielding gases like argon, helium, or carbon dioxide. The market is driven by the increasing demand for high-quality welding in various industries such as automotive, aerospace, and construction. As industries continue to expand and modernize, the need for advanced welding techniques and equipment grows, thereby boosting the demand for MIG TIG flow meters. These devices not only enhance the quality of welds but also contribute to cost savings by optimizing gas usage. The market is characterized by technological advancements, with manufacturers focusing on developing more accurate, reliable, and user-friendly flow meters. Additionally, the growing emphasis on automation and the integration of smart technologies in industrial processes are expected to further propel the market's growth. Overall, the Global MIG TIG Flow Meters Market plays a vital role in supporting the efficiency and effectiveness of welding operations across various sectors.

Single-Stage Flow Meters, Dual-Stage Flow Meters in the Global MIG TIG Flow Meters Market:

Single-stage flow meters and dual-stage flow meters are integral components of the Global MIG TIG Flow Meters Market, each serving distinct purposes and offering unique advantages. Single-stage flow meters are designed to regulate the flow of gases in a straightforward manner, making them ideal for applications where precise control is not as critical. These meters are typically more affordable and easier to install, making them a popular choice for small to medium-sized operations. They work by allowing gas to flow through a single chamber, where the pressure is reduced to a usable level before being delivered to the welding torch. This simplicity makes single-stage flow meters a reliable option for many welding applications, particularly in environments where the gas supply pressure remains relatively constant. On the other hand, dual-stage flow meters offer a higher level of precision and control, making them suitable for more demanding applications. These meters feature two chambers, allowing for a more gradual reduction in gas pressure. This design ensures a consistent flow rate, even when there are fluctuations in the supply pressure. Dual-stage flow meters are often used in high-precision welding tasks, where maintaining a stable gas flow is crucial for achieving optimal results. They are particularly beneficial in industries where the quality of the weld is paramount, such as aerospace and automotive manufacturing. The choice between single-stage and dual-stage flow meters largely depends on the specific requirements of the welding operation, including the desired level of precision, the stability of the gas supply, and budget considerations. As the Global MIG TIG Flow Meters Market continues to evolve, manufacturers are focusing on enhancing the performance and reliability of both single-stage and dual-stage flow meters. Innovations in materials and design are leading to more durable and efficient products, capable of withstanding the rigors of industrial environments. Additionally, the integration of digital technologies is enabling more precise monitoring and control of gas flow, further enhancing the capabilities of these devices. As industries increasingly prioritize efficiency and quality, the demand for advanced flow meters is expected to grow, driving further innovation and development in this market segment. Overall, single-stage and dual-stage flow meters play a crucial role in the Global MIG TIG Flow Meters Market, providing essential tools for ensuring the success of welding operations across a wide range of industries.

Automotive Manufacturing, Aerospace Industry, Construction Industry, Oil and Gas Industry, Pharmaceutical Industry, Chemical Industry, Food and Beverage Industry, Others in the Global MIG TIG Flow Meters Market:

The Global MIG TIG Flow Meters Market finds extensive application across various industries, each leveraging the unique capabilities of these devices to enhance their operations. In the automotive manufacturing sector, MIG TIG flow meters are essential for producing high-quality welds that meet stringent safety and performance standards. These meters ensure precise control of shielding gases, which is crucial for achieving strong, durable welds in vehicle components. Similarly, in the aerospace industry, where precision and reliability are paramount, flow meters play a critical role in the fabrication of aircraft parts. The ability to maintain a consistent gas flow is vital for producing welds that can withstand the extreme conditions encountered during flight. In the construction industry, MIG TIG flow meters are used to support the welding of structural components, ensuring the integrity and safety of buildings and infrastructure. The oil and gas industry also relies on these devices to facilitate the welding of pipelines and other critical infrastructure, where the quality of the weld can have significant safety and environmental implications. In the pharmaceutical industry, flow meters are used in the production of equipment and machinery that require precise welding to maintain sterility and functionality. The chemical industry benefits from the use of flow meters in the fabrication of processing equipment, where accurate gas flow control is essential for ensuring the integrity of welds in corrosive environments. The food and beverage industry utilizes MIG TIG flow meters in the production of stainless steel equipment, where high-quality welds are necessary to meet hygiene standards. Beyond these specific industries, MIG TIG flow meters are also used in various other applications, including the production of consumer goods, electronics, and renewable energy infrastructure. The versatility and reliability of these devices make them indispensable tools for any industry that requires high-quality welding. As industries continue to evolve and demand more efficient and precise welding solutions, the Global MIG TIG Flow Meters Market is poised to play an increasingly important role in supporting these advancements.

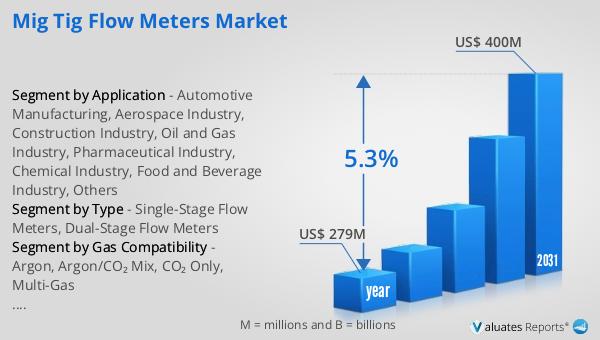

Global MIG TIG Flow Meters Market Outlook:

In 2024, the global market for MIG TIG Flow Meters was valued at approximately $279 million. Looking ahead, this market is anticipated to expand significantly, reaching an estimated value of $400 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.3% over the forecast period. The steady increase in market size underscores the rising demand for MIG TIG flow meters across various industries. As sectors such as automotive, aerospace, and construction continue to prioritize high-quality welding processes, the need for precise and reliable flow meters becomes increasingly critical. The projected growth also reflects the ongoing advancements in technology and the integration of smart features in flow meters, which enhance their functionality and user-friendliness. As industries strive for greater efficiency and cost-effectiveness, the adoption of advanced flow meters is expected to rise, further driving market expansion. The Global MIG TIG Flow Meters Market is thus poised for robust growth, supported by the increasing emphasis on precision welding and the continuous evolution of industrial processes. This positive market outlook highlights the essential role that MIG TIG flow meters play in facilitating high-quality welding operations across a diverse range of applications.

| Report Metric | Details |

| Report Name | MIG TIG Flow Meters Market |

| Accounted market size in year | US$ 279 million |

| Forecasted market size in 2031 | US$ 400 million |

| CAGR | 5.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Gas Compatibility |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Victor Technologies, Harris Products Group, Smith Equipment, Matheson Tri-Gas, Air Liquide Welding, GCE Group, Hobart Welding Products, CK Worldwide, RegO Products, Western Enterprises, Parker Hannifin, Rotarex, Linde plc, Uniweld Products, Inc., Radnor by Airgas |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |