What is Global Water-Based Pigment for Digital Textile Printing Market?

The Global Water-Based Pigment for Digital Textile Printing Market is a dynamic and evolving sector that plays a crucial role in the textile industry. This market focuses on the use of water-based pigments in digital textile printing, which is a modern method of printing designs onto fabrics. Unlike traditional printing methods, digital textile printing offers greater flexibility, precision, and efficiency. Water-based pigments are particularly favored in this process due to their eco-friendly nature, as they contain fewer volatile organic compounds (VOCs) and are less harmful to the environment. These pigments provide vibrant colors and excellent durability, making them ideal for a wide range of textile applications. The market is driven by the increasing demand for sustainable and high-quality textile products, as well as advancements in digital printing technology. As consumers become more environmentally conscious, the preference for water-based pigments is expected to grow, further propelling the market. Additionally, the ability to produce customized and intricate designs with ease makes digital textile printing an attractive option for manufacturers and designers alike. Overall, the Global Water-Based Pigment for Digital Textile Printing Market is poised for significant growth as it continues to innovate and meet the demands of a rapidly changing industry.

Self-Crosslinking, External Crosslinking in the Global Water-Based Pigment for Digital Textile Printing Market:

In the realm of the Global Water-Based Pigment for Digital Textile Printing Market, the concepts of self-crosslinking and external crosslinking are pivotal in enhancing the performance and durability of printed textiles. Self-crosslinking refers to a process where the polymer chains in the pigment bind together without the need for an external agent. This intrinsic ability to form crosslinks results in a stable and robust film on the fabric, which enhances the wash and rub fastness of the printed design. Self-crosslinking is particularly advantageous as it simplifies the production process, reduces the need for additional chemicals, and often results in a softer hand feel of the fabric. On the other hand, external crosslinking involves the addition of a crosslinking agent that facilitates the bonding of polymer chains. This method allows for greater control over the crosslinking process, enabling manufacturers to tailor the properties of the printed fabric to specific requirements. External crosslinking can enhance the mechanical properties of the print, such as its resistance to abrasion and its overall durability. Both self-crosslinking and external crosslinking play crucial roles in the digital textile printing market, offering solutions that cater to different needs and preferences. The choice between the two often depends on the desired characteristics of the final product, the type of fabric being used, and the specific application. For instance, in applications where a softer feel is prioritized, self-crosslinking may be preferred. Conversely, for applications requiring enhanced durability and resistance, external crosslinking might be the better option. The ongoing research and development in this field continue to push the boundaries of what is possible, leading to innovative solutions that meet the diverse demands of the textile industry. As the market for water-based pigments in digital textile printing grows, the importance of understanding and utilizing these crosslinking techniques becomes increasingly evident. Manufacturers and designers are constantly exploring new ways to optimize these processes to achieve the best possible outcomes for their products. The interplay between self-crosslinking and external crosslinking is a testament to the complexity and sophistication of the digital textile printing market, highlighting the need for expertise and innovation in this ever-evolving field.

Cloth, Home Decor, Luxury Goods, Others in the Global Water-Based Pigment for Digital Textile Printing Market:

The Global Water-Based Pigment for Digital Textile Printing Market finds extensive usage across various sectors, including clothing, home decor, luxury goods, and others. In the clothing industry, digital textile printing with water-based pigments offers unparalleled advantages. It allows for the creation of intricate and vibrant designs on fabrics, catering to the fashion industry's demand for unique and customizable apparel. The eco-friendly nature of water-based pigments aligns with the growing trend towards sustainable fashion, making it a preferred choice for designers and manufacturers. In home decor, digital textile printing is revolutionizing the way we design and produce items such as curtains, upholstery, and bed linens. The ability to print detailed and colorful patterns directly onto fabrics opens up endless possibilities for interior design, allowing consumers to personalize their living spaces with ease. Water-based pigments ensure that these products are not only visually appealing but also safe for indoor use, as they emit fewer harmful chemicals. The luxury goods sector also benefits from the precision and quality offered by digital textile printing. High-end brands can produce limited edition items with intricate designs that reflect their brand's identity and craftsmanship. The use of water-based pigments ensures that these products maintain their vibrancy and quality over time, meeting the high standards expected in the luxury market. Beyond these specific sectors, the versatility of digital textile printing extends to other areas such as sportswear, accessories, and promotional items. The ability to produce small batches of customized products quickly and efficiently makes it an attractive option for businesses looking to offer personalized solutions to their customers. Overall, the Global Water-Based Pigment for Digital Textile Printing Market is transforming the textile industry by providing innovative and sustainable solutions that cater to a wide range of applications. As technology continues to advance, the potential for digital textile printing to reshape the way we produce and consume textiles is immense, promising a future where creativity and sustainability go hand in hand.

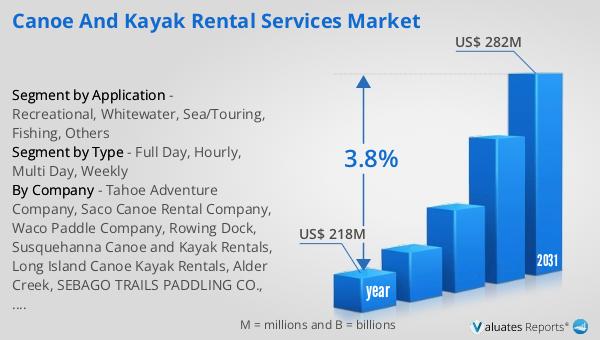

Global Water-Based Pigment for Digital Textile Printing Market Outlook:

The global market for water-based pigments used in digital textile printing was valued at approximately $1,724 million in 2024. It is anticipated to grow significantly, reaching an estimated value of $2,442 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.9% over the forecast period. This upward trend reflects the increasing demand for sustainable and high-quality textile printing solutions. The market's expansion is driven by several factors, including advancements in digital printing technology, the rising popularity of customized and personalized textile products, and the growing awareness of environmental sustainability. As consumers and manufacturers alike seek eco-friendly alternatives, water-based pigments are becoming the preferred choice due to their reduced environmental impact compared to traditional solvent-based inks. The projected growth of this market underscores the importance of innovation and adaptation in the textile industry, as companies strive to meet the evolving needs and preferences of their customers. With the continued development of new technologies and materials, the Global Water-Based Pigment for Digital Textile Printing Market is poised to play a pivotal role in shaping the future of textile production and design.

| Report Metric | Details |

| Report Name | Water-Based Pigment for Digital Textile Printing Market |

| Accounted market size in year | US$ 1724 million |

| Forecasted market size in 2031 | US$ 2442 million |

| CAGR | 4.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Adhesives |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DuPont, Sun Chemical, covestro, EFI Reggiani, SPGPrints, DyStar, Mimaki, Kornit Digital, Archroma, BASF, LANXESS, Achitex Minerva, Chromatech, Proquimac, Eagle Specialty Products, ROHA, PNM |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |