What is Global Industrial CT Inspection Services Market?

The Global Industrial CT Inspection Services Market is a specialized sector within the broader field of industrial inspection and quality assurance. This market focuses on the use of computed tomography (CT) technology to inspect and analyze the internal structures of industrial components and assemblies. Unlike traditional inspection methods, CT inspection provides a non-destructive means of examining the internal features of an object, allowing for detailed analysis without causing any damage. This technology is particularly valuable in industries where precision and reliability are critical, such as aerospace, automotive, electronics, and manufacturing. By using X-rays to create cross-sectional images, CT inspection can reveal defects, measure dimensions, and verify the integrity of complex parts. The demand for industrial CT inspection services is driven by the need for high-quality standards, regulatory compliance, and the increasing complexity of modern industrial components. As industries continue to innovate and develop more intricate designs, the role of CT inspection becomes even more crucial in ensuring product safety and performance. The market is characterized by advancements in CT technology, including higher resolution imaging and faster processing times, which enhance the capabilities and efficiency of inspection services.

Micron-level CT, Nanometer-level CT in the Global Industrial CT Inspection Services Market:

Micron-level CT and Nanometer-level CT are advanced imaging technologies that play a significant role in the Global Industrial CT Inspection Services Market. These technologies are distinguished by their ability to provide extremely high-resolution images, allowing for detailed analysis of even the smallest features within an object. Micron-level CT refers to computed tomography that can achieve resolutions in the micrometer range, typically between 1 to 100 micrometers. This level of detail is essential for inspecting small components or features within larger assemblies, where precision is paramount. Industries such as electronics, medical devices, and precision engineering benefit greatly from micron-level CT, as it enables the detection of minute defects, measurement of thin walls, and verification of complex geometries. The ability to visualize internal structures with such clarity helps manufacturers ensure the quality and reliability of their products, reducing the risk of failures and recalls. On the other hand, Nanometer-level CT pushes the boundaries of resolution even further, achieving imaging capabilities in the nanometer range, which is less than 1 micrometer. This technology is particularly valuable in fields where the utmost precision is required, such as semiconductor manufacturing, nanotechnology, and advanced materials research. Nanometer-level CT allows for the examination of structures at the atomic or molecular level, providing insights into material properties, internal stresses, and potential failure points. The ability to inspect at such a fine scale is crucial for developing new materials and technologies, as it enables researchers and engineers to understand the fundamental characteristics of their designs. In the semiconductor industry, for example, nanometer-level CT can be used to inspect the intricate features of microchips, ensuring that they meet the stringent quality standards required for high-performance applications. Both micron-level and nanometer-level CT technologies are integral to the advancement of the Global Industrial CT Inspection Services Market. As industries continue to push the limits of what is possible in terms of design and functionality, the demand for high-resolution inspection services will only increase. These technologies not only provide a means of ensuring quality and reliability but also drive innovation by enabling the development of new materials and products. The ability to visualize and analyze internal structures with such precision is a powerful tool for manufacturers, researchers, and engineers, allowing them to optimize their designs and processes for maximum efficiency and performance. As the market for industrial CT inspection services grows, we can expect to see further advancements in imaging technology, leading to even greater capabilities and applications across a wide range of industries.

Personal Use, Commercial Use in the Global Industrial CT Inspection Services Market:

The Global Industrial CT Inspection Services Market finds its application in both personal and commercial use, each with distinct requirements and benefits. In the realm of personal use, CT inspection services are primarily utilized by hobbyists, small-scale manufacturers, and individuals involved in custom or artisanal production. For these users, CT inspection provides a means of ensuring the quality and integrity of their creations, whether they are crafting intricate jewelry, custom electronics, or bespoke mechanical components. The ability to inspect internal structures without causing damage is particularly valuable for those working with delicate or expensive materials, as it allows for quality assurance without the risk of loss. Additionally, personal users may leverage CT inspection to reverse-engineer existing products, gaining insights into their construction and design for educational or creative purposes. In the commercial sector, the application of Global Industrial CT Inspection Services is far more extensive and varied. Industries such as aerospace, automotive, electronics, and medical devices rely heavily on CT inspection to maintain high standards of quality and safety. In aerospace, for example, CT inspection is used to verify the integrity of critical components, such as turbine blades and structural elements, ensuring that they meet the rigorous demands of flight. Similarly, in the automotive industry, CT inspection helps manufacturers detect defects in engine parts, transmission systems, and other vital components, reducing the risk of failures and enhancing vehicle reliability. The electronics industry benefits from CT inspection by using it to analyze the internal features of circuit boards and microchips, ensuring that they function correctly and meet performance specifications. Medical device manufacturers also rely on CT inspection to ensure the safety and efficacy of their products. By examining the internal structures of implants, surgical instruments, and diagnostic equipment, manufacturers can identify potential defects or weaknesses that could compromise patient safety. The ability to conduct non-destructive testing is particularly important in this field, as it allows for thorough inspection without damaging the product. Furthermore, CT inspection services are used in research and development across various industries, providing valuable insights into material properties, structural integrity, and design optimization. By leveraging the capabilities of CT technology, companies can innovate and improve their products, gaining a competitive edge in the market. Overall, the Global Industrial CT Inspection Services Market plays a crucial role in both personal and commercial applications, offering a reliable means of quality assurance and product development. As industries continue to evolve and demand higher standards of precision and reliability, the importance of CT inspection services will only grow. Whether for personal projects or large-scale manufacturing, the ability to visualize and analyze internal structures with such accuracy is an invaluable asset, driving innovation and ensuring the highest levels of quality and safety.

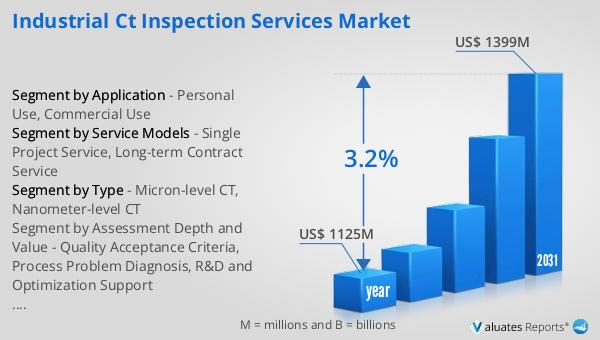

Global Industrial CT Inspection Services Market Outlook:

The outlook for the Global Industrial CT Inspection Services Market indicates a steady growth trajectory over the coming years. In 2024, the market was valued at approximately $1,125 million, reflecting the increasing demand for high-resolution inspection services across various industries. By 2031, the market is expected to expand to a revised size of around $1,399 million, driven by a compound annual growth rate (CAGR) of 3.2% during the forecast period. This growth can be attributed to several factors, including advancements in CT technology, the rising complexity of industrial components, and the need for stringent quality assurance measures. As industries continue to innovate and develop more intricate designs, the demand for precise and reliable inspection services will only increase. The market's expansion is also supported by the growing adoption of CT inspection in emerging sectors, such as renewable energy, biotechnology, and additive manufacturing. These industries require advanced inspection solutions to ensure the quality and performance of their products, further fueling the demand for CT services. Overall, the Global Industrial CT Inspection Services Market is poised for significant growth, driven by technological advancements and the increasing need for high-quality standards across various sectors.

| Report Metric | Details |

| Report Name | Industrial CT Inspection Services Market |

| Accounted market size in year | US$ 1125 million |

| Forecasted market size in 2031 | US$ 1399 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Service Models |

|

| Segment by Assessment Depth and Value |

|

| Segment by Application |

|

| By Region |

|

| By Company | Jesse Garant Metrology, MicronPA, RX Solutions, ZEISS, Testia, Nikon Metrology, Diondo, North Star Imaging, Nel Pretech, 3D Engineering Solutions, Microvista GmbH, Avonix Imaging, X-Sight X-ray |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |