What is Global Glass Fiber Composite Diaphragm Market?

The Global Glass Fiber Composite Diaphragm Market is a specialized segment within the broader composite materials industry, focusing on the production and application of diaphragms made from glass fiber composites. These diaphragms are crucial components in various audio and acoustic devices, offering a blend of strength, durability, and acoustic performance. Glass fiber composites are known for their lightweight nature and high tensile strength, making them ideal for applications where both performance and longevity are critical. The market is driven by the increasing demand for high-quality audio equipment, where these diaphragms are used to enhance sound clarity and reduce distortion. Additionally, the growing consumer electronics industry, with its emphasis on portable and high-performance audio devices, further propels the demand for glass fiber composite diaphragms. As technology advances, the market continues to evolve, with manufacturers focusing on innovation to improve the acoustic properties and durability of these diaphragms. The global reach of this market is evident as it caters to diverse industries, including automotive, consumer electronics, and professional audio equipment, reflecting its integral role in modern technology.

Homogeneous Mixture Type, Woven & Impregnated Type, Coating Type in the Global Glass Fiber Composite Diaphragm Market:

The Global Glass Fiber Composite Diaphragm Market is characterized by various types of products, each serving distinct purposes and applications. Among these, the Homogeneous Mixture Type is a significant category. This type involves the uniform distribution of glass fibers within a matrix material, resulting in a consistent and balanced diaphragm. The homogeneous mixture ensures that the diaphragm exhibits uniform mechanical properties, which is crucial for maintaining sound quality and performance across different frequencies. This type is particularly favored in applications where precision and consistency are paramount, such as in high-end audio equipment. The uniformity in the material composition helps in minimizing any potential weak points, thereby enhancing the durability and longevity of the diaphragm. Next, we have the Woven & Impregnated Type, which involves weaving glass fibers into a fabric-like structure and then impregnating it with a resin or polymer. This method provides a unique combination of flexibility and strength, making it suitable for applications that require a balance between rigidity and pliability. The woven structure allows for better control over the diaphragm's mechanical properties, enabling manufacturers to tailor the product to specific acoustic requirements. This type is often used in applications where the diaphragm needs to withstand significant mechanical stress while maintaining its acoustic performance. The impregnation process further enhances the diaphragm's resistance to environmental factors such as moisture and temperature fluctuations, ensuring reliable performance over time. The Coating Type is another important category within the Global Glass Fiber Composite Diaphragm Market. This type involves applying a protective or functional coating to the surface of the diaphragm. The coating can serve multiple purposes, such as enhancing the diaphragm's resistance to environmental factors, improving its acoustic properties, or providing additional mechanical strength. Coatings can be made from various materials, including polymers, metals, or ceramics, each offering distinct advantages. For instance, a polymer coating might be used to enhance the diaphragm's flexibility and resistance to moisture, while a metal coating could improve its thermal conductivity and durability. The choice of coating material and application method can significantly impact the diaphragm's performance, making it a critical consideration for manufacturers. In summary, the Global Glass Fiber Composite Diaphragm Market encompasses a diverse range of product types, each with its unique characteristics and applications. The Homogeneous Mixture Type offers uniformity and consistency, making it ideal for precision applications. The Woven & Impregnated Type provides a balance of flexibility and strength, suitable for demanding environments. Meanwhile, the Coating Type offers additional protection and performance enhancements, catering to specific needs and challenges. As the market continues to grow and evolve, manufacturers are likely to explore new materials and technologies to further enhance the performance and versatility of glass fiber composite diaphragms.

Midrange Speaker, Subwoofer, Others in the Global Glass Fiber Composite Diaphragm Market:

The Global Glass Fiber Composite Diaphragm Market finds extensive usage in various audio applications, including midrange speakers, subwoofers, and other audio devices. In midrange speakers, glass fiber composite diaphragms play a crucial role in delivering clear and accurate sound reproduction. These diaphragms are designed to handle a wide range of frequencies, ensuring that the midrange sounds, such as vocals and instruments, are reproduced with precision and clarity. The lightweight nature of glass fiber composites allows for quick and responsive movement of the diaphragm, which is essential for maintaining sound accuracy and reducing distortion. This makes them an ideal choice for high-fidelity audio systems where sound quality is of utmost importance. In subwoofers, glass fiber composite diaphragms are used to produce deep and powerful bass sounds. The strength and rigidity of glass fiber composites enable the diaphragm to withstand the high pressures and forces generated by low-frequency sounds. This ensures that the subwoofer can deliver impactful bass without compromising on sound quality or durability. The ability of glass fiber composite diaphragms to maintain their structural integrity under extreme conditions makes them a preferred choice for subwoofers used in both home audio systems and professional sound equipment. Additionally, the use of these diaphragms in subwoofers helps in minimizing unwanted vibrations and resonance, resulting in cleaner and more accurate bass reproduction. Beyond midrange speakers and subwoofers, glass fiber composite diaphragms are also used in a variety of other audio devices. This includes applications in portable speakers, headphones, and automotive audio systems. In portable speakers, the lightweight and durable nature of glass fiber composite diaphragms make them ideal for devices that require both portability and high-performance sound. In headphones, these diaphragms contribute to delivering immersive audio experiences by providing clear and detailed sound across a wide frequency range. In automotive audio systems, glass fiber composite diaphragms are used to enhance the overall sound quality within the vehicle, providing passengers with a premium listening experience. Overall, the usage of glass fiber composite diaphragms in the Global Glass Fiber Composite Diaphragm Market spans a wide range of audio applications, each benefiting from the unique properties of these materials. Whether it's delivering clear midrange sounds, producing powerful bass, or enhancing the audio experience in portable and automotive devices, glass fiber composite diaphragms play a vital role in modern audio technology. As the demand for high-quality audio continues to grow, the importance of these diaphragms in achieving superior sound performance remains significant.

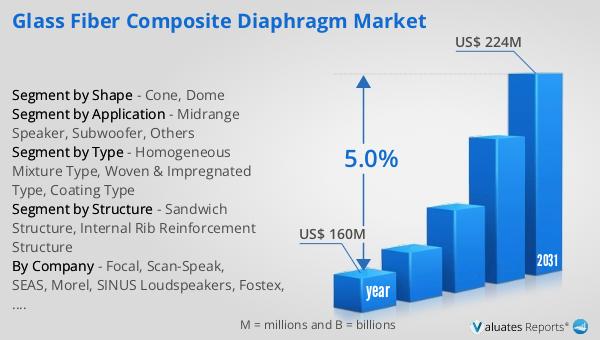

Global Glass Fiber Composite Diaphragm Market Outlook:

In 2024, the global market for Glass Fiber Composite Diaphragms was valued at approximately $160 million. Looking ahead, this market is expected to experience significant growth, reaching an estimated size of $224 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.0% over the forecast period. The steady increase in market value underscores the rising demand for glass fiber composite diaphragms across various industries, driven by their superior performance characteristics and versatility. As industries continue to seek advanced materials that offer a combination of strength, durability, and acoustic performance, the market for glass fiber composite diaphragms is poised for continued expansion. This growth is further supported by ongoing technological advancements and innovations in the field of composite materials, which are expected to enhance the performance and application range of these diaphragms. The projected market size and growth rate highlight the significant opportunities for manufacturers and stakeholders in the Global Glass Fiber Composite Diaphragm Market, as they strive to meet the evolving needs of consumers and industries worldwide.

| Report Metric | Details |

| Report Name | Glass Fiber Composite Diaphragm Market |

| Accounted market size in year | US$ 160 million |

| Forecasted market size in 2031 | US$ 224 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Structure |

|

| Segment by Shape |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Focal, Scan-Speak, SEAS, Morel, SINUS Loudspeakers, Fostex, Polk Audio, HECO Audio |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |