What is Global Zirconium Tetrachloride Precursor Market?

The Global Zirconium Tetrachloride Precursor Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of zirconium tetrachloride, a chemical compound used primarily as a precursor in various industrial applications. This market is driven by the demand for high-purity zirconium compounds, which are essential in advanced manufacturing processes, particularly in the electronics and ceramics industries. Zirconium tetrachloride is a white crystalline solid that is highly reactive and is used in the synthesis of other zirconium compounds. Its unique properties make it a valuable component in the production of thin films, coatings, and other materials that require precise chemical composition and high purity. The market is characterized by a growing demand for high-performance materials, driven by technological advancements and the need for more efficient manufacturing processes. As industries continue to innovate and seek out materials that offer superior performance, the demand for zirconium tetrachloride is expected to increase, making this market an important area of focus for chemical manufacturers and researchers alike. The global reach of this market underscores its significance, as it plays a crucial role in the supply chain of various high-tech industries.

Purity 3N, Purity 4N, Purity 5N, Purity 6N in the Global Zirconium Tetrachloride Precursor Market:

In the Global Zirconium Tetrachloride Precursor Market, purity levels such as 3N, 4N, 5N, and 6N refer to the degree of purity of the zirconium tetrachloride, with each 'N' representing a nine in the percentage of purity. For instance, 3N purity means 99.9% pure, 4N means 99.99% pure, and so on. These varying levels of purity are critical because they determine the suitability of the zirconium tetrachloride for different applications. Purity 3N is often used in applications where ultra-high purity is not as critical, such as in some basic industrial processes or where cost considerations are paramount. As the purity level increases to 4N, the zirconium tetrachloride becomes suitable for more demanding applications, such as in certain types of ceramics and electronics where impurities could significantly affect performance. Purity 5N and 6N are used in the most demanding applications, such as in the semiconductor industry, where even the smallest impurity can lead to defects in the final product. These high-purity levels are achieved through advanced purification processes that remove impurities to an extremely low level, ensuring that the zirconium tetrachloride meets the stringent requirements of high-tech applications. The demand for higher purity levels is driven by the need for materials that can perform reliably in extreme conditions, such as high temperatures or corrosive environments. As industries continue to push the boundaries of technology, the demand for high-purity zirconium tetrachloride is expected to grow, making it a critical component in the development of new materials and technologies. The ability to produce zirconium tetrachloride at these high purity levels is a testament to the advancements in chemical processing and purification technologies, which have enabled manufacturers to meet the increasingly stringent demands of modern industries. This focus on purity is not just about meeting current needs but also about anticipating future requirements as industries evolve and new applications for zirconium tetrachloride are discovered. The market for high-purity zirconium tetrachloride is thus a dynamic and rapidly evolving segment, driven by the continuous advancement of technology and the ever-increasing demand for high-performance materials.

Thin Film Deposition, CVD and ALD Processes, Other in the Global Zirconium Tetrachloride Precursor Market:

The Global Zirconium Tetrachloride Precursor Market finds its usage in several key areas, including thin film deposition, chemical vapor deposition (CVD), atomic layer deposition (ALD) processes, and other specialized applications. In thin film deposition, zirconium tetrachloride is used as a precursor material to create thin layers of zirconium-based compounds on various substrates. These thin films are crucial in the production of electronic components, optical coatings, and protective layers, where precise control over thickness and composition is essential. The use of zirconium tetrachloride in thin film deposition allows manufacturers to achieve high-quality coatings with excellent adhesion, uniformity, and durability. In CVD processes, zirconium tetrachloride serves as a volatile precursor that decomposes at high temperatures to form a solid film on a substrate. This process is widely used in the semiconductor industry to produce high-purity, high-performance materials that are essential for the fabrication of integrated circuits and other electronic devices. The ability to control the deposition process at the atomic level makes CVD an ideal method for producing complex, multi-layered structures with precise chemical composition and physical properties. Similarly, in ALD processes, zirconium tetrachloride is used to deposit thin films one atomic layer at a time, allowing for unparalleled control over film thickness and composition. This precision is particularly important in the production of advanced electronic devices, where even the slightest variation in film properties can lead to significant performance issues. Beyond these applications, zirconium tetrachloride is also used in other specialized areas, such as the production of advanced ceramics, where its high reactivity and purity make it an ideal precursor for creating materials with exceptional thermal and mechanical properties. The versatility of zirconium tetrachloride as a precursor material makes it an invaluable component in a wide range of industrial processes, driving demand across multiple sectors. As industries continue to innovate and develop new technologies, the role of zirconium tetrachloride in these processes is expected to grow, highlighting its importance as a key material in the advancement of modern technology.

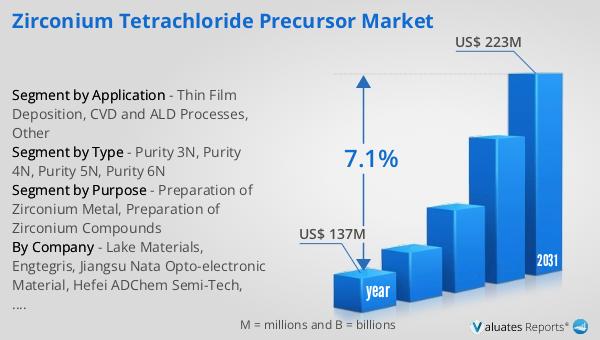

Global Zirconium Tetrachloride Precursor Market Outlook:

The global market for Zirconium Tetrachloride Precursor was valued at $137 million in 2024 and is anticipated to expand to a revised size of $223 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.1% during the forecast period. This growth trajectory underscores the increasing demand for zirconium tetrachloride across various industries, driven by its critical role in high-tech manufacturing processes. The market's expansion is indicative of the broader trend towards the adoption of advanced materials that offer superior performance and reliability. As industries such as electronics, ceramics, and semiconductors continue to evolve, the need for high-purity zirconium tetrachloride is expected to rise, fueling market growth. This upward trend is also supported by advancements in chemical processing technologies, which have enabled manufacturers to produce zirconium tetrachloride at higher purity levels, meeting the stringent requirements of modern applications. The projected growth of the market reflects the ongoing innovation and development within the industry, as well as the increasing importance of zirconium tetrachloride as a key material in the production of high-performance products. As the market continues to expand, it presents significant opportunities for manufacturers and researchers to explore new applications and develop innovative solutions that leverage the unique properties of zirconium tetrachloride.

| Report Metric | Details |

| Report Name | Zirconium Tetrachloride Precursor Market |

| Accounted market size in year | US$ 137 million |

| Forecasted market size in 2031 | US$ 223 million |

| CAGR | 7.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Purpose |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Lake Materials, Engtegris, Jiangsu Nata Opto-electronic Material, Hefei ADChem Semi-Tech, Fujian Fudou New Materials, Full Chain Materials International |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |