What is Global Anti-Veining Agent Market?

The Global Anti-Veining Agent Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of agents that prevent veining defects in metal castings. Veining, a common defect in metal casting, occurs when cracks or fissures form on the surface of cast metal, compromising its structural integrity and aesthetic appeal. Anti-veining agents are crucial in the foundry industry as they help improve the quality and durability of metal castings by minimizing these defects. These agents are typically added to sand molds or cores used in the casting process, ensuring a smoother and more uniform surface finish. The market for anti-veining agents is driven by the growing demand for high-quality metal castings in various industries, including automotive, aerospace, and construction. As these industries continue to expand, the need for effective solutions to enhance casting quality becomes increasingly important. The market is characterized by a range of products, including both organic and inorganic agents, each offering unique benefits and applications. With advancements in technology and increasing awareness about the importance of casting quality, the Global Anti-Veining Agent Market is poised for significant growth in the coming years.

Inorganic, Organic in the Global Anti-Veining Agent Market:

In the Global Anti-Veining Agent Market, both inorganic and organic agents play pivotal roles, each offering distinct advantages and applications. Inorganic anti-veining agents are typically composed of minerals and compounds such as silica, alumina, and zircon. These agents are favored for their high thermal stability and ability to withstand extreme temperatures, making them ideal for use in high-temperature casting processes. Inorganic agents work by forming a protective barrier on the surface of the sand mold or core, preventing the formation of cracks and fissures during the casting process. This results in a smoother and more uniform surface finish, enhancing the overall quality of the metal casting. Additionally, inorganic agents are often more cost-effective compared to their organic counterparts, making them a popular choice in industries where cost efficiency is a priority. On the other hand, organic anti-veining agents are derived from natural sources such as cellulose, starch, and other plant-based materials. These agents are known for their environmentally friendly properties, as they are biodegradable and do not release harmful emissions during the casting process. Organic agents work by creating a flexible and resilient layer on the surface of the sand mold or core, absorbing the stresses and strains that occur during the casting process. This helps to prevent the formation of veining defects, resulting in a higher quality metal casting. Organic agents are particularly favored in industries where environmental sustainability is a key concern, as they offer a more eco-friendly alternative to traditional inorganic agents. The choice between inorganic and organic anti-veining agents often depends on the specific requirements of the casting process and the desired properties of the final product. In some cases, a combination of both types of agents may be used to achieve optimal results. For example, inorganic agents may be used to provide thermal stability and structural integrity, while organic agents may be added to enhance flexibility and reduce environmental impact. This combination approach allows manufacturers to tailor their casting processes to meet the specific needs of their customers, ensuring the highest quality and performance of the final product. In recent years, there has been a growing trend towards the development of hybrid anti-veining agents that combine the benefits of both inorganic and organic materials. These hybrid agents offer a unique combination of thermal stability, environmental sustainability, and cost efficiency, making them an attractive option for many industries. As research and development in this area continue to advance, it is expected that hybrid agents will play an increasingly important role in the Global Anti-Veining Agent Market. Overall, the choice between inorganic and organic anti-veining agents is influenced by a variety of factors, including cost, environmental impact, and the specific requirements of the casting process. As the demand for high-quality metal castings continues to grow, the Global Anti-Veining Agent Market is expected to see increased innovation and diversification, with new products and technologies emerging to meet the evolving needs of the industry.

Hot Box, Cold Box in the Global Anti-Veining Agent Market:

The usage of Global Anti-Veining Agent Market products in hot box and cold box processes is crucial for ensuring the quality and integrity of metal castings. In the hot box process, sand cores are produced by mixing sand with a resin binder and then curing the mixture at high temperatures. This process is widely used in the foundry industry due to its ability to produce strong and durable cores with excellent dimensional accuracy. However, the high temperatures involved in the hot box process can lead to the formation of veining defects, which can compromise the quality of the final casting. Anti-veining agents are added to the sand mixture to prevent these defects by forming a protective barrier on the surface of the core, reducing the likelihood of cracks and fissures forming during the casting process. This results in a smoother and more uniform surface finish, enhancing the overall quality of the metal casting. In the cold box process, sand cores are produced by mixing sand with a resin binder and then curing the mixture at room temperature using a gaseous catalyst. This process is favored for its ability to produce high-quality cores with excellent surface finish and dimensional accuracy, without the need for high temperatures. However, the cold box process is also susceptible to veining defects, particularly in complex or intricate castings. Anti-veining agents are used in the cold box process to prevent these defects by creating a flexible and resilient layer on the surface of the core, absorbing the stresses and strains that occur during the casting process. This helps to prevent the formation of cracks and fissures, resulting in a higher quality metal casting. The choice of anti-veining agent for use in hot box and cold box processes often depends on the specific requirements of the casting process and the desired properties of the final product. In some cases, a combination of both inorganic and organic agents may be used to achieve optimal results. For example, inorganic agents may be used to provide thermal stability and structural integrity, while organic agents may be added to enhance flexibility and reduce environmental impact. This combination approach allows manufacturers to tailor their casting processes to meet the specific needs of their customers, ensuring the highest quality and performance of the final product. Overall, the use of anti-veining agents in hot box and cold box processes is essential for ensuring the quality and integrity of metal castings. As the demand for high-quality metal castings continues to grow, the Global Anti-Veining Agent Market is expected to see increased innovation and diversification, with new products and technologies emerging to meet the evolving needs of the industry.

Global Anti-Veining Agent Market Outlook:

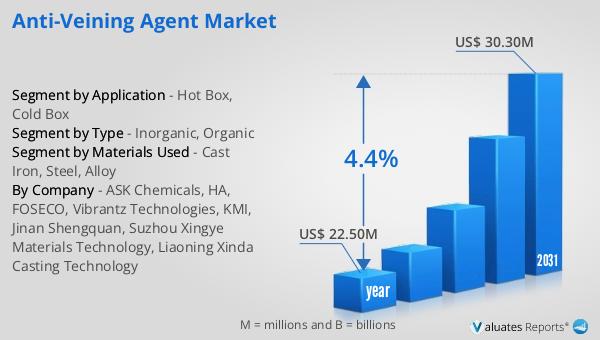

The global market for Anti-Veining Agents was valued at approximately $22.50 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $30.30 million by the year 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 4.4% over the forecast period. The steady increase in market size underscores the rising demand for anti-veining agents across various industries, driven by the need for high-quality metal castings. As industries such as automotive, aerospace, and construction continue to expand, the demand for effective solutions to enhance casting quality becomes increasingly important. The market's growth is also fueled by advancements in technology and increasing awareness about the importance of casting quality. With the ongoing development of new products and technologies, the Global Anti-Veining Agent Market is poised for significant growth in the coming years. This growth is expected to be driven by the increasing adoption of anti-veining agents in various casting processes, as well as the development of new and innovative products that meet the evolving needs of the industry. As a result, the Global Anti-Veining Agent Market is expected to continue its upward trajectory, providing ample opportunities for growth and innovation in the years to come.

| Report Metric | Details |

| Report Name | Anti-Veining Agent Market |

| Accounted market size in year | US$ 22.50 million |

| Forecasted market size in 2031 | US$ 30.30 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Materials Used |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ASK Chemicals, HA, FOSECO, Vibrantz Technologies, KMI, Jinan Shengquan, Suzhou Xingye Materials Technology, Liaoning Xinda Casting Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |