What is Global Flame Retardant PC Insulation Material Market?

The Global Flame Retardant PC Insulation Material Market is a specialized segment within the broader insulation materials industry, focusing on materials that are designed to resist ignition and prevent the spread of fire. These materials are primarily composed of polycarbonate (PC), a type of plastic known for its durability and heat resistance. Flame retardant PC insulation materials are essential in various industries where safety and compliance with fire safety standards are critical. They are used to enhance the fire resistance of products and components, thereby reducing the risk of fire-related incidents. The market for these materials is driven by increasing safety regulations, technological advancements, and the growing demand for fire-resistant materials in sectors such as electronics, automotive, aerospace, and construction. As industries continue to prioritize safety and sustainability, the demand for flame retardant PC insulation materials is expected to grow, offering opportunities for innovation and development in this field. The market is characterized by a diverse range of products, each tailored to meet specific industry requirements and standards, ensuring that they provide effective fire protection while maintaining the performance and integrity of the insulated products.

Halogenated Flame-retardant PC, Halogen-free Flame-retardant PC in the Global Flame Retardant PC Insulation Material Market:

Halogenated flame-retardant PC and halogen-free flame-retardant PC are two primary categories within the Global Flame Retardant PC Insulation Material Market, each with distinct characteristics and applications. Halogenated flame retardants are compounds that contain halogens such as chlorine or bromine. These materials are effective in inhibiting the spread of fire by releasing halogen radicals that interfere with the combustion process. Halogenated flame-retardant PCs are widely used due to their cost-effectiveness and efficiency in providing fire resistance. However, they have come under scrutiny due to environmental and health concerns, as the combustion of halogenated materials can release toxic gases and persistent organic pollutants. This has led to a growing interest in halogen-free alternatives. Halogen-free flame-retardant PCs, on the other hand, do not contain halogens and are designed to offer fire resistance without the associated environmental and health risks. These materials often use alternative flame-retardant additives such as phosphorus, nitrogen, or inorganic compounds. Halogen-free flame-retardant PCs are increasingly favored in applications where environmental sustainability and health safety are prioritized. They are particularly popular in regions with stringent environmental regulations, such as Europe and parts of Asia. The shift towards halogen-free materials is driven by the need to comply with regulations such as the Restriction of Hazardous Substances (RoHS) directive and the Waste Electrical and Electronic Equipment (WEEE) directive, which aim to reduce the environmental impact of electronic waste. Despite the higher cost of halogen-free flame-retardant PCs compared to their halogenated counterparts, their adoption is growing as industries seek to balance performance, safety, and sustainability. The development of new formulations and technologies is also contributing to the improved performance and cost-effectiveness of halogen-free flame-retardant PCs, making them a viable option for a wide range of applications. As the market evolves, manufacturers are focusing on innovation and collaboration to address the challenges and opportunities presented by the transition to halogen-free materials. This includes investing in research and development to enhance the properties of flame-retardant PCs, such as their thermal stability, mechanical strength, and processability. The competition between halogenated and halogen-free flame-retardant PCs is shaping the dynamics of the Global Flame Retardant PC Insulation Material Market, with each type offering unique advantages and trade-offs. Ultimately, the choice between halogenated and halogen-free flame-retardant PCs depends on factors such as regulatory requirements, cost considerations, and specific application needs. As industries continue to prioritize safety, sustainability, and compliance, the demand for both types of flame-retardant PCs is expected to grow, driving further innovation and development in this field.

Electronics, Automotive Industry, Aerospace, Others in the Global Flame Retardant PC Insulation Material Market:

The usage of Global Flame Retardant PC Insulation Material Market spans several key industries, each with specific requirements and applications. In the electronics industry, flame retardant PC insulation materials are crucial for ensuring the safety and reliability of electronic devices and components. These materials are used in the manufacturing of circuit boards, connectors, and enclosures, where they help prevent electrical fires and ensure compliance with safety standards. The demand for flame retardant materials in electronics is driven by the increasing complexity and miniaturization of electronic devices, which require enhanced fire protection to mitigate the risk of overheating and short circuits. In the automotive industry, flame retardant PC insulation materials are used in various components such as dashboards, interior panels, and electrical systems. The automotive sector prioritizes safety and performance, and the use of flame retardant materials helps manufacturers meet stringent safety regulations and improve the fire resistance of vehicles. As the industry shifts towards electric and hybrid vehicles, the demand for flame retardant materials is expected to increase, as these vehicles require additional fire protection for their battery systems and electrical components. In the aerospace industry, flame retardant PC insulation materials are used in the construction of aircraft interiors, wiring systems, and other critical components. The aerospace sector has some of the most stringent safety standards, and the use of flame retardant materials is essential to ensure passenger safety and compliance with regulations. The lightweight and durable properties of polycarbonate make it an ideal choice for aerospace applications, where weight reduction and fire resistance are critical considerations. Beyond these industries, flame retardant PC insulation materials are also used in construction, telecommunications, and consumer goods. In construction, they are used in building materials and insulation products to enhance fire safety and comply with building codes. In telecommunications, flame retardant materials are used in the production of cables and connectors, where they help prevent fire hazards and ensure the reliability of communication networks. In consumer goods, flame retardant materials are used in the manufacturing of household appliances, furniture, and other products to enhance safety and reduce the risk of fire-related incidents. The versatility and effectiveness of flame retardant PC insulation materials make them a valuable asset across various industries, where they contribute to improved safety, performance, and compliance with regulations. As industries continue to evolve and prioritize safety and sustainability, the demand for flame retardant PC insulation materials is expected to grow, driving further innovation and development in this field.

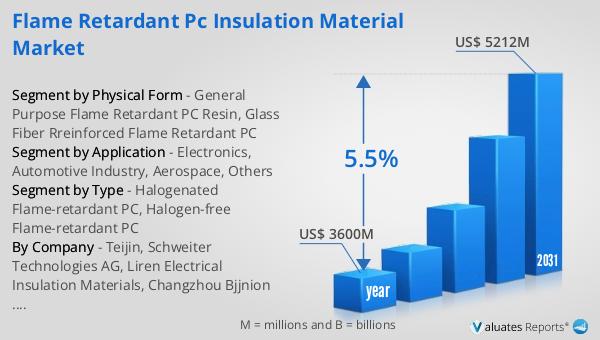

Global Flame Retardant PC Insulation Material Market Outlook:

The global market for Flame Retardant PC Insulation Material was valued at $3.6 billion in 2024, and it is anticipated to expand to a revised size of $5.212 billion by 2031, reflecting a compound annual growth rate (CAGR) of 5.5% over the forecast period. This growth trajectory underscores the increasing demand for flame retardant materials across various industries, driven by heightened safety regulations and the need for enhanced fire protection. The market's expansion is indicative of the broader trend towards prioritizing safety and sustainability in product design and manufacturing. As industries such as electronics, automotive, and aerospace continue to evolve, the need for reliable and effective flame retardant materials becomes more pronounced. The projected growth of the market highlights the opportunities for innovation and development in this field, as manufacturers seek to meet the evolving needs of their customers while complying with regulatory requirements. The market's growth is also a reflection of the increasing awareness of the environmental and health impacts of traditional flame retardant materials, leading to a shift towards more sustainable and eco-friendly alternatives. As the market continues to expand, it presents opportunities for companies to differentiate themselves through innovation and the development of new products that meet the changing demands of the industry. The growth of the Global Flame Retardant PC Insulation Material Market is a testament to the importance of safety and sustainability in today's world, and it underscores the need for continued investment in research and development to drive further advancements in this field.

| Report Metric | Details |

| Report Name | Flame Retardant PC Insulation Material Market |

| Accounted market size in year | US$ 3600 million |

| Forecasted market size in 2031 | US$ 5212 million |

| CAGR | 5.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Physical Form |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Teijin, Schweiter Technologies AG, Liren Electrical Insulation Materials, Changzhou Bjjnion Film Science & Technology Co., Ltd, KUMTEK, Isolite Insulating Products Co., Ltd, Sabic, Zhejiang Hengfeng Insulation Materials Co., Ltd, Suzhou Aomei Materials Technology Co., Ltd, Shenzhen Tianchang Technology Co., Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |