What is Global AGV Transport Cart Market?

The Global AGV (Automated Guided Vehicle) Transport Cart Market is a rapidly evolving sector that focuses on the development and deployment of automated vehicles designed to transport goods and materials within various environments. These AGV transport carts are equipped with advanced navigation systems, sensors, and software that allow them to operate autonomously, reducing the need for human intervention. They are widely used in industries such as manufacturing, logistics, and warehousing, where they help streamline operations, enhance productivity, and reduce labor costs. The market is driven by the increasing demand for automation in material handling processes, the need for efficient and reliable transportation solutions, and the growing trend of smart factories and Industry 4.0. As businesses continue to seek ways to optimize their operations and improve efficiency, the adoption of AGV transport carts is expected to rise, further fueling market growth. These vehicles are not only cost-effective but also contribute to safer working environments by minimizing the risk of accidents and injuries associated with manual handling. Overall, the Global AGV Transport Cart Market represents a significant opportunity for innovation and growth in the field of automated material handling solutions.

Towed, Submerged, Docking in the Global AGV Transport Cart Market:

In the Global AGV Transport Cart Market, various types of AGV systems are employed to meet the diverse needs of different industries. Among these, towed, submerged, and docking AGVs are prominent categories, each offering unique advantages and applications. Towed AGVs are designed to pull carts or trailers loaded with goods, making them ideal for transporting heavy loads over long distances within a facility. These AGVs are commonly used in manufacturing plants and warehouses where large volumes of materials need to be moved efficiently. They are equipped with robust towing mechanisms and advanced navigation systems that enable them to follow predetermined paths accurately. Submerged AGVs, on the other hand, operate beneath the load they carry. These AGVs are particularly useful in environments where space is limited, as they can maneuver under pallets or containers, lifting and transporting them to their destination. Submerged AGVs are often used in distribution centers and logistics hubs where quick and precise movement of goods is essential. Docking AGVs are designed to interface with docking stations or conveyors, facilitating seamless transfer of materials between different stages of the production or distribution process. These AGVs are equipped with sophisticated docking mechanisms that ensure precise alignment and connection with the docking station, enabling efficient loading and unloading of goods. Docking AGVs are commonly used in automated warehouses and manufacturing facilities where integration with existing systems is crucial. Each of these AGV types plays a vital role in enhancing operational efficiency, reducing labor costs, and improving overall productivity in various industries. As technology continues to advance, the capabilities of these AGVs are expected to expand, offering even greater flexibility and functionality to meet the evolving needs of businesses worldwide.

Logistics Warehouses, Industrial Manufacturing, Port Terminals, Others in the Global AGV Transport Cart Market:

The usage of Global AGV Transport Cart Market solutions spans across various sectors, including logistics warehouses, industrial manufacturing, port terminals, and other areas, each benefiting from the unique capabilities of AGVs. In logistics warehouses, AGVs are employed to automate the movement of goods, from receiving to storage and shipping. They help streamline operations by efficiently transporting pallets, containers, and packages, reducing the reliance on manual labor and minimizing the risk of errors. AGVs in warehouses are often integrated with warehouse management systems, enabling real-time tracking and optimization of inventory flow. In industrial manufacturing, AGVs play a crucial role in automating the transportation of raw materials, components, and finished products between different stages of the production process. They enhance production efficiency by ensuring timely delivery of materials to assembly lines, reducing downtime, and improving overall workflow. AGVs in manufacturing environments are often customized to handle specific tasks, such as transporting heavy machinery parts or delicate electronic components. At port terminals, AGVs are used to automate the movement of containers between ships, storage areas, and transportation vehicles. They help optimize port operations by reducing turnaround times, increasing throughput, and enhancing safety by minimizing human involvement in hazardous areas. AGVs in port terminals are equipped with advanced navigation and collision avoidance systems to operate efficiently in dynamic and congested environments. Beyond these sectors, AGVs are also used in various other applications, such as hospitals for transporting medical supplies, in airports for baggage handling, and in retail environments for automating the movement of goods. The versatility and adaptability of AGVs make them an invaluable asset in any industry seeking to improve operational efficiency, reduce costs, and enhance safety.

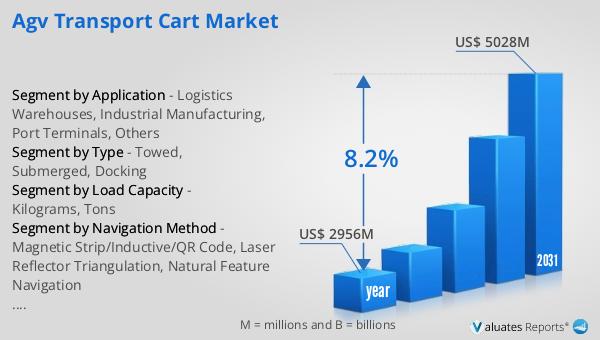

Global AGV Transport Cart Market Outlook:

The global market for AGV Transport Cart was valued at approximately $2,956 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $5,028 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.2% over the forecast period. The increasing demand for automation in material handling processes across various industries is a key driver of this market expansion. As businesses strive to enhance operational efficiency, reduce labor costs, and improve safety, the adoption of AGV transport carts is expected to rise. These automated vehicles offer a reliable and cost-effective solution for transporting goods and materials within facilities, contributing to streamlined operations and increased productivity. The market's growth is also fueled by advancements in technology, such as improved navigation systems, sensors, and software, which enhance the capabilities and performance of AGVs. Additionally, the growing trend of smart factories and Industry 4.0 is expected to further boost the demand for AGV transport carts, as companies seek to integrate automated solutions into their operations. Overall, the Global AGV Transport Cart Market presents a promising opportunity for innovation and growth, with significant potential for further development and adoption in the coming years.

| Report Metric | Details |

| Report Name | AGV Transport Cart Market |

| Accounted market size in year | US$ 2956 million |

| Forecasted market size in 2031 | US$ 5028 million |

| CAGR | 8.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Navigation Method |

|

| Segment by Load Capacity |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Daifuku, JBT Corporation, Dematic, Toyota Industries Corporation, Swisslog, SIASUN Robot & Automation, Meidensha Corporation, EK Automation, Seegrid, CSG Smart Science and Technology, SSI Schaefer, Shenzhen Uwant Technology, Perfect, Guangzhou Sinorobot Intelligent Technology, Anqiu Boyang Machinery, New Newton(Taizhou) Forklift Truck, Tuling Robot |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |