What is Global Sulfonic Acid Curing Agent for Furan Resin Market?

The Global Sulfonic Acid Curing Agent for Furan Resin Market is a specialized segment within the chemical industry that focuses on the production and application of sulfonic acid-based curing agents specifically designed for furan resins. Furan resins are a type of thermosetting polymer derived from furfuryl alcohol, which is obtained from agricultural byproducts like corn cobs and sugarcane bagasse. These resins are known for their excellent thermal stability, chemical resistance, and mechanical strength, making them ideal for various industrial applications. Sulfonic acid curing agents play a crucial role in the polymerization process of furan resins, facilitating the cross-linking of polymer chains to form a rigid, three-dimensional network. This curing process enhances the performance characteristics of furan resins, making them suitable for use in high-temperature environments and applications requiring strong chemical resistance. The market for these curing agents is driven by the growing demand for furan resins in industries such as foundry, construction, and coatings, where their unique properties offer significant advantages over traditional materials. As industries continue to seek sustainable and high-performance materials, the demand for sulfonic acid curing agents for furan resins is expected to grow.

Free Phenols≤1.5%, Free Phenols≤2.0%, Free Phenols≤5.0%, Free Phenols≤12.0%, Other in the Global Sulfonic Acid Curing Agent for Furan Resin Market:

In the Global Sulfonic Acid Curing Agent for Furan Resin Market, the specification of free phenols is a critical factor that influences the performance and application of the curing agents. Free phenols refer to the unreacted phenolic compounds present in the curing agent, which can affect the curing process and the final properties of the furan resin. The market categorizes these curing agents based on the percentage of free phenols, with common specifications being Free Phenols≤1.5%, Free Phenols≤2.0%, Free Phenols≤5.0%, and Free Phenols≤12.0%. Each specification serves different industrial needs and applications. For instance, curing agents with Free Phenols≤1.5% are typically used in applications where minimal phenolic content is crucial to avoid any adverse effects on the resin's performance, such as in high-precision casting or in environments with stringent environmental regulations. These low-phenol curing agents ensure that the final product has minimal emissions and reduced environmental impact. On the other hand, curing agents with Free Phenols≤2.0% and Free Phenols≤5.0% offer a balance between performance and cost, making them suitable for general industrial applications where moderate phenolic content is acceptable. These specifications are often used in the production of foundry molds and cores, where the curing speed and mechanical properties of the resin are important. The Free Phenols≤12.0% category represents curing agents with higher phenolic content, which are typically used in applications where cost-effectiveness is a priority, and the environmental impact is less of a concern. These curing agents are often employed in large-scale industrial applications where the primary focus is on achieving the desired mechanical properties at a lower cost. Additionally, the "Other" category includes curing agents with unique formulations or those that do not fit into the standard phenolic content specifications. These may be tailored for specific applications or developed to meet particular industry standards. The choice of curing agent specification depends on various factors, including the desired properties of the final product, environmental regulations, and cost considerations. As industries continue to evolve and demand more sustainable and efficient materials, the development and adoption of curing agents with lower free phenol content are expected to increase. This trend is driven by the need to reduce emissions and improve the environmental footprint of industrial processes. Overall, the specification of free phenols in sulfonic acid curing agents plays a vital role in determining their suitability for different applications and industries.

Automotive, Electronics, Aerospace, Energy, Other in the Global Sulfonic Acid Curing Agent for Furan Resin Market:

The Global Sulfonic Acid Curing Agent for Furan Resin Market finds extensive usage across various industries, including automotive, electronics, aerospace, energy, and others, due to the unique properties of furan resins enhanced by these curing agents. In the automotive industry, sulfonic acid curing agents are used to produce high-performance furan resin components that can withstand extreme temperatures and harsh chemical environments. These components are often used in engine parts, exhaust systems, and other critical areas where durability and thermal stability are essential. The ability of furan resins to maintain their mechanical properties under high stress and temperature conditions makes them ideal for automotive applications. In the electronics industry, sulfonic acid curing agents are used to produce furan resin-based components that offer excellent electrical insulation and thermal resistance. These properties are crucial for electronic devices that operate under high temperatures or in demanding environments. Furan resins are used in the production of circuit boards, connectors, and other electronic components where reliability and performance are critical. The aerospace industry also benefits from the use of sulfonic acid curing agents for furan resins, as these materials provide the necessary strength and thermal resistance required for aerospace applications. Furan resins are used in the production of lightweight composite materials, which are essential for reducing the weight of aircraft and improving fuel efficiency. The energy sector utilizes sulfonic acid curing agents for furan resins in the production of components for power generation and distribution systems. The thermal stability and chemical resistance of furan resins make them suitable for use in high-temperature environments, such as in turbines and other power generation equipment. Additionally, furan resins are used in the production of insulation materials for electrical cables and transformers, where their excellent dielectric properties are beneficial. Beyond these industries, sulfonic acid curing agents for furan resins are used in various other applications, including construction, coatings, and adhesives. In construction, furan resins are used to produce corrosion-resistant coatings and linings for industrial structures, while in the coatings industry, they are used to create high-performance protective coatings for metal surfaces. The versatility and performance of furan resins, enhanced by sulfonic acid curing agents, make them a valuable material across a wide range of industries. As industries continue to seek materials that offer a combination of performance, sustainability, and cost-effectiveness, the demand for sulfonic acid curing agents for furan resins is expected to grow.

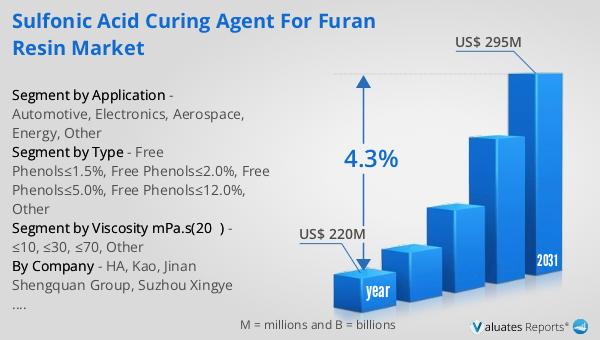

Global Sulfonic Acid Curing Agent for Furan Resin Market Outlook:

The global market for Sulfonic Acid Curing Agent for Furan Resin was valued at US$ 220 million in 2024, and it is anticipated to expand to a revised size of US$ 295 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.3% over the forecast period. This growth trajectory underscores the increasing demand for sulfonic acid curing agents in various industrial applications, driven by the unique properties they impart to furan resins. The market's expansion is fueled by the growing adoption of furan resins in industries such as automotive, electronics, aerospace, and energy, where their thermal stability, chemical resistance, and mechanical strength offer significant advantages. As industries continue to prioritize sustainability and performance, the demand for high-quality curing agents that enhance the properties of furan resins is expected to rise. The projected growth of the market also reflects the ongoing efforts to develop and commercialize new formulations of sulfonic acid curing agents with improved environmental profiles and performance characteristics. As a result, the market is poised for steady growth, driven by the increasing

| Report Metric | Details |

| Report Name | Sulfonic Acid Curing Agent for Furan Resin Market |

| Accounted market size in year | US$ 220 million |

| Forecasted market size in 2031 | US$ 295 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Viscosity mPa.s(20℃) |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | HA, Kao, Jinan Shengquan Group, Suzhou Xingye Materials Technology, Sichuan Dongshu New Materials, Shandong Yongchuang Material Technology, Jiangsu Huagang Material Technology, Shandong Huahao New Energy Technology, KOCEL, Liaoning Xinda Casting Technology, Zibo Shuangde Chemical, Zhejiang Tianyi New Materials Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |