What is Global Unbonded Marine Pipeline Market?

The Global Unbonded Marine Pipeline Market refers to the industry focused on the development, production, and deployment of unbonded pipelines used in marine environments. These pipelines are crucial for transporting fluids such as oil, gas, and chemicals across vast oceanic distances. Unlike bonded pipelines, unbonded marine pipelines are designed with layers that allow for flexibility and movement, which is essential in the dynamic and often harsh conditions of the sea. This flexibility helps in accommodating the movements caused by waves, currents, and other environmental factors, thereby reducing the risk of damage and ensuring the safe and efficient transport of materials. The market for these pipelines is driven by the increasing demand for energy and resources, necessitating the exploration and extraction of offshore reserves. As industries continue to expand their operations into deeper and more challenging waters, the need for reliable and durable pipeline solutions becomes even more critical. The Global Unbonded Marine Pipeline Market is thus a vital component of the broader energy and marine infrastructure sectors, playing a key role in supporting global energy needs and facilitating international trade.

Smooth Pipe, Rough Pipe in the Global Unbonded Marine Pipeline Market:

In the context of the Global Unbonded Marine Pipeline Market, smooth pipes and rough pipes serve distinct purposes and are chosen based on specific operational requirements. Smooth pipes, as the name suggests, have a polished interior surface that minimizes friction and resistance when fluids pass through. This characteristic is particularly advantageous in scenarios where the efficient and rapid transport of fluids is necessary. The reduced friction not only enhances flow rates but also contributes to lower energy consumption, as less force is required to move the fluids through the pipeline. This makes smooth pipes an ideal choice for applications where high throughput and energy efficiency are priorities, such as in the transportation of oil and gas over long distances. Additionally, the smooth interior surface helps in reducing the accumulation of deposits and sediments, thereby minimizing maintenance needs and prolonging the pipeline's operational lifespan. On the other hand, rough pipes are characterized by their textured interior surfaces, which can increase friction and resistance. While this might seem disadvantageous at first glance, rough pipes are specifically designed for applications where controlled flow rates are necessary. The increased friction can help in managing the speed and pressure of the fluids, making rough pipes suitable for scenarios where precise flow control is required. This is particularly relevant in chemical processing applications, where the accurate mixing and reaction of different substances are critical. Furthermore, the textured surface of rough pipes can enhance the structural integrity of the pipeline, providing additional strength and durability in challenging marine environments. The choice between smooth and rough pipes in the Global Unbonded Marine Pipeline Market is thus a strategic decision, influenced by factors such as the type of fluid being transported, the desired flow rate, and the specific environmental conditions of the deployment area. Both types of pipes play essential roles in ensuring the safe, efficient, and reliable transport of materials across marine environments, contributing to the overall effectiveness of the pipeline infrastructure. As the demand for energy and resources continues to grow, the importance of selecting the appropriate pipeline type becomes increasingly significant, underscoring the need for careful planning and consideration in the design and implementation of marine pipeline systems.

Oil & Gas, Chemical, Marine Engineering, Others in the Global Unbonded Marine Pipeline Market:

The Global Unbonded Marine Pipeline Market finds extensive usage across various sectors, including Oil & Gas, Chemical, Marine Engineering, and others, each with its unique requirements and challenges. In the Oil & Gas industry, unbonded marine pipelines are indispensable for the transportation of crude oil and natural gas from offshore drilling platforms to onshore facilities. These pipelines enable the efficient and safe transfer of hydrocarbons over long distances, often traversing deep and turbulent waters. The flexibility and durability of unbonded pipelines make them well-suited to withstand the dynamic marine environment, ensuring the continuous flow of resources and minimizing the risk of leaks or ruptures. In the Chemical sector, unbonded marine pipelines are used to transport various chemical products and raw materials between production facilities and storage terminals. The ability to customize the pipeline's design to accommodate different chemical properties and flow requirements is a significant advantage, allowing for the safe and efficient handling of potentially hazardous substances. Marine Engineering applications also benefit from the use of unbonded marine pipelines, particularly in the construction and maintenance of underwater infrastructure. These pipelines are used to transport construction materials, such as concrete and aggregates, as well as to facilitate the removal of dredged materials from construction sites. The adaptability and resilience of unbonded pipelines make them an ideal choice for supporting complex marine engineering projects, where reliability and performance are paramount. Beyond these primary sectors, unbonded marine pipelines are also employed in various other applications, such as the transportation of potable water and wastewater in coastal and island communities. The versatility and robustness of these pipelines make them a valuable asset in addressing the diverse needs of different industries, contributing to the overall development and sustainability of marine infrastructure. As global demand for energy and resources continues to rise, the role of unbonded marine pipelines in supporting these critical sectors becomes increasingly important, highlighting the need for ongoing innovation and investment in this vital market.

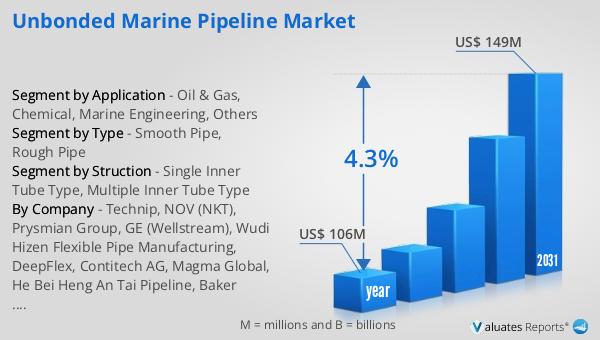

Global Unbonded Marine Pipeline Market Outlook:

The global market for Unbonded Marine Pipeline, which was valued at $106 million in 2024, is anticipated to expand to a revised size of $149 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.3% over the forecast period. This growth trajectory underscores the increasing demand for unbonded marine pipelines, driven by the expanding energy needs and the exploration of offshore resources. The market's steady growth is indicative of the critical role these pipelines play in facilitating the safe and efficient transport of fluids across marine environments. As industries continue to push the boundaries of offshore exploration and production, the need for reliable and durable pipeline solutions becomes more pronounced. The projected growth in the market size highlights the ongoing investment and innovation in pipeline technology, aimed at enhancing performance, safety, and environmental sustainability. This upward trend also reflects the broader global shift towards more sustainable and efficient energy infrastructure, as countries and companies strive to meet their energy needs while minimizing environmental impact. The Global Unbonded Marine Pipeline Market is thus poised for continued expansion, driven by technological advancements and the increasing demand for energy and resources. As the market evolves, stakeholders will need to focus on developing innovative solutions that address the challenges of operating in complex and dynamic marine environments, ensuring the continued growth and success of this vital industry.

| Report Metric | Details |

| Report Name | Unbonded Marine Pipeline Market |

| Accounted market size in year | US$ 106 million |

| Forecasted market size in 2031 | US$ 149 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Struction |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Technip, NOV (NKT), Prysmian Group, GE (Wellstream), Wudi Hizen Flexible Pipe Manufacturing, DeepFlex, Contitech AG, Magma Global, He Bei Heng An Tai Pipeline, Baker Hughes |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |