What is Global Cylindrical Coil Springs Market?

The Global Cylindrical Coil Springs Market is a significant segment within the broader mechanical components industry, focusing on the production and distribution of cylindrical coil springs. These springs are essential mechanical devices that store and release energy, providing force or maintaining tension in various applications. They are characterized by their helical shape and are made from materials like steel, stainless steel, and other alloys, which offer durability and flexibility. The market encompasses a wide range of industries, including automotive, aerospace, industrial machinery, and consumer appliances, among others. The demand for cylindrical coil springs is driven by their critical role in ensuring the smooth operation of mechanical systems, absorbing shocks, and maintaining the desired tension or compression. As industries continue to evolve and innovate, the need for reliable and efficient spring solutions remains paramount, making the Global Cylindrical Coil Springs Market a vital component of modern manufacturing and engineering. The market's growth is influenced by technological advancements, material innovations, and the increasing demand for high-performance springs in various applications.

Compression Springs, Extension Springs, Torsion Springs in the Global Cylindrical Coil Springs Market:

Compression springs, extension springs, and torsion springs are three primary types of cylindrical coil springs, each serving distinct functions within the Global Cylindrical Coil Springs Market. Compression springs are designed to resist compressive forces and are commonly used in applications where a pushing or compressing force is required. They are typically found in automotive suspensions, industrial machinery, and consumer appliances, where they help absorb shocks and maintain stability. These springs are characterized by their ability to return to their original shape after being compressed, making them ideal for applications that require repeated compression and release cycles. Extension springs, on the other hand, are designed to absorb and store energy by resisting pulling forces. They are often used in applications where a pulling or stretching force is needed, such as in garage doors, trampolines, and various mechanical assemblies. Extension springs are equipped with hooks or loops at their ends, allowing them to be attached to other components and provide the necessary tension. Torsion springs are unique in that they work by twisting rather than compressing or extending. They are used in applications where rotational force is required, such as in hinges, levers, and various mechanical devices. Torsion springs are designed to store and release angular energy, providing the necessary torque to move or hold components in place. Each type of spring plays a crucial role in the functionality and efficiency of mechanical systems, and their selection depends on the specific requirements of the application. The Global Cylindrical Coil Springs Market continues to innovate and adapt to meet the diverse needs of industries, ensuring that these essential components remain integral to modern engineering and manufacturing processes.

Automotive, Aerospace & Defense, Industrial Machinery, Energy & Utilities, Consumer Appliances, Others in the Global Cylindrical Coil Springs Market:

The Global Cylindrical Coil Springs Market finds extensive usage across various industries, each benefiting from the unique properties and functions of these springs. In the automotive industry, cylindrical coil springs are crucial components in vehicle suspensions, providing the necessary support and stability for a smooth ride. They help absorb shocks from road irregularities, ensuring passenger comfort and vehicle control. In the aerospace and defense sectors, these springs are used in various applications, including landing gear systems, control surfaces, and weapon systems, where they provide the necessary force and stability for safe and efficient operation. Industrial machinery relies heavily on cylindrical coil springs for their ability to absorb shocks, maintain tension, and provide the necessary force for various mechanical processes. These springs are used in manufacturing equipment, conveyor systems, and other machinery, where they help ensure smooth and efficient operation. In the energy and utilities sector, cylindrical coil springs are used in various applications, including power generation equipment, oil and gas exploration, and renewable energy systems. They provide the necessary force and stability for efficient energy production and distribution. Consumer appliances, such as washing machines, refrigerators, and vacuum cleaners, also rely on cylindrical coil springs for their functionality. These springs help absorb shocks, maintain tension, and provide the necessary force for various appliance functions. Other industries, including medical devices, construction, and electronics, also benefit from the unique properties of cylindrical coil springs, making them an essential component in a wide range of applications. The versatility and reliability of these springs ensure their continued demand across various sectors, driving the growth of the Global Cylindrical Coil Springs Market.

Global Cylindrical Coil Springs Market Outlook:

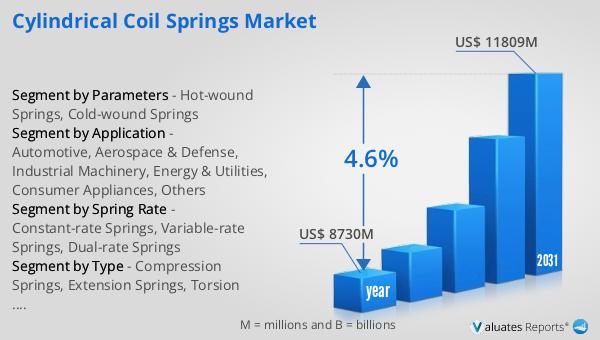

In 2024, the global market for Cylindrical Coil Springs was valued at approximately $8.73 billion. Looking ahead, this market is expected to grow significantly, reaching an estimated size of $11.81 billion by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.6% over the forecast period. This steady increase in market size underscores the rising demand for cylindrical coil springs across various industries. The growth is driven by the need for reliable and efficient spring solutions in automotive, aerospace, industrial machinery, and consumer appliances, among others. As industries continue to innovate and evolve, the demand for high-performance springs that can withstand rigorous conditions and provide consistent performance is expected to rise. The market's expansion is also supported by advancements in materials and manufacturing processes, which enhance the durability and functionality of cylindrical coil springs. This positive market outlook highlights the critical role that cylindrical coil springs play in modern engineering and manufacturing, ensuring their continued relevance and demand in the years to come.

| Report Metric | Details |

| Report Name | Cylindrical Coil Springs Market |

| Accounted market size in year | US$ 8730 million |

| Forecasted market size in 2031 | US$ 11809 million |

| CAGR | 4.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Spring Rate |

|

| Segment by Parameters |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | NHK Spring, Mubea Group, Heinrich Eibach, H&R Spezialfedern, Lesjöfors Group, Daewon Kangup, Ace Wire Spring, Coiling Technologies, Stalder Spring Works, Sterling Spring, C&F Wire Products, PT Indospring, Precision Coil Spring, Vulcan Spring & Mfg, Zhejiang Jinchang Spring, Supreme Spring, Jamshedpur Springs, Alberta Springs |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |