What is Global Water Displacing Rust Preventative Market?

The Global Water Displacing Rust Preventative Market is a specialized segment within the broader corrosion prevention industry. This market focuses on products designed to protect metal surfaces from rust and corrosion by displacing water, which is a primary cause of rust formation. These products are essential in various industries, including automotive, aerospace, marine, and manufacturing, where metal components are frequently exposed to moisture and harsh environmental conditions. The market is driven by the increasing demand for efficient and long-lasting rust prevention solutions, as well as the growing awareness of the economic and safety implications of rust damage. Innovations in chemical formulations and the development of environmentally friendly products are also contributing to the market's growth. As industries continue to prioritize the longevity and reliability of their metal assets, the demand for water displacing rust preventatives is expected to rise, making this market a critical component of industrial maintenance and asset protection strategies.

Solvent-Based, Oil-Based, Emulsion-Based in the Global Water Displacing Rust Preventative Market:

The Global Water Displacing Rust Preventative Market is characterized by various types of formulations, each catering to specific needs and applications. Solvent-based rust preventatives are among the most traditional and widely used types. These products typically consist of a blend of solvents and rust-inhibiting compounds that form a protective barrier on metal surfaces. The solvent acts as a carrier, allowing the rust preventative to penetrate into crevices and hard-to-reach areas, ensuring comprehensive protection. Solvent-based formulations are known for their quick drying times and ease of application, making them ideal for industries that require rapid processing and turnaround times. However, they often contain volatile organic compounds (VOCs), which can pose environmental and health concerns. As a result, there is a growing trend towards developing low-VOC or VOC-free solvent-based products to meet regulatory requirements and consumer preferences for greener solutions. Oil-based rust preventatives, on the other hand, rely on oils as the primary carrier for rust-inhibiting agents. These products are particularly effective in providing long-term protection, as the oil forms a thick, durable layer that resists moisture and other corrosive elements. Oil-based formulations are often used in applications where extended protection is needed, such as in the storage of metal parts or equipment that may not be in regular use. They are also favored in situations where the aesthetic appearance of the metal is not a primary concern, as the oil can leave a visible residue. Despite their effectiveness, oil-based rust preventatives can be challenging to remove and may require additional cleaning processes before the metal can be painted or further processed. Emulsion-based rust preventatives represent a more modern approach, combining the benefits of both solvent and oil-based formulations. These products typically consist of a water-based emulsion that includes rust inhibitors and other protective agents. Emulsion-based rust preventatives are valued for their environmental friendliness, as they generally contain lower levels of VOCs and are easier to clean up compared to traditional solvent or oil-based products. They are particularly suitable for applications where environmental regulations are stringent, or where ease of removal is a priority. Additionally, emulsion-based products can offer excellent protection without the greasy residue associated with oil-based formulations, making them ideal for applications where cleanliness and appearance are important. Each type of rust preventative has its own set of advantages and limitations, and the choice of which to use often depends on the specific requirements of the application, including the type of metal, the environmental conditions, and the desired duration of protection. As the Global Water Displacing Rust Preventative Market continues to evolve, manufacturers are investing in research and development to create more effective and environmentally friendly products that meet the diverse needs of their customers. This ongoing innovation is crucial for maintaining the market's growth and ensuring that industries can continue to protect their valuable metal assets from the damaging effects of rust and corrosion.

Spray Type, Dip Type, Brush Type in the Global Water Displacing Rust Preventative Market:

The usage of Global Water Displacing Rust Preventative Market products varies significantly depending on the application method, with spray type, dip type, and brush type being the most common. Spray type applications are particularly popular in industries where speed and efficiency are critical. This method involves using a spray gun or aerosol can to apply the rust preventative evenly across the metal surface. The advantage of spray application is its ability to cover large areas quickly and uniformly, making it ideal for treating large metal structures or components. Additionally, spray application can reach intricate areas and complex geometries that might be challenging to protect using other methods. However, it requires proper ventilation and safety precautions to manage overspray and inhalation risks, especially when using solvent-based products. Dip type application is another widely used method, particularly in manufacturing and industrial settings where batch processing is common. In this method, metal parts are submerged in a tank containing the rust preventative solution, ensuring complete coverage. Dip application is highly effective for small to medium-sized components and is often used for parts that will be stored for extended periods. This method ensures that all surfaces, including internal cavities and hard-to-reach areas, are thoroughly coated. While dip application provides excellent protection, it can be resource-intensive, requiring significant amounts of rust preventative solution and specialized equipment for handling and processing the parts. Brush type application is typically used for smaller or more delicate components, or in situations where precision is required. This method involves manually applying the rust preventative using a brush, allowing for targeted application and control over the thickness of the coating. Brush application is ideal for touch-up work, maintenance, or when dealing with complex shapes that require careful attention to detail. While it is labor-intensive and may not be suitable for large-scale applications, brush application offers the advantage of minimizing waste and ensuring that the rust preventative is applied exactly where it is needed. Each application method has its own set of benefits and challenges, and the choice of which to use often depends on the specific requirements of the task at hand. Factors such as the size and shape of the metal components, the desired level of protection, and the available resources all play a role in determining the most appropriate application method. As industries continue to seek efficient and effective ways to protect their metal assets, the versatility and adaptability of water displacing rust preventatives make them an essential tool in the fight against corrosion.

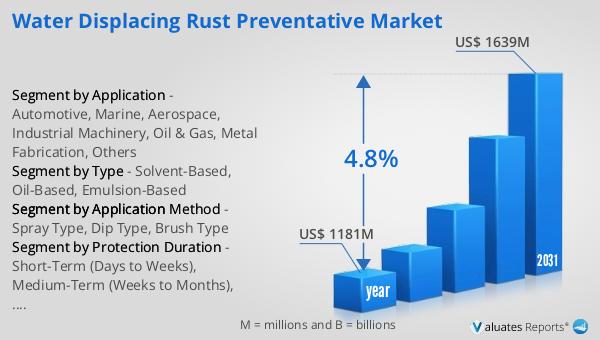

Global Water Displacing Rust Preventative Market Outlook:

In 2024, the global market for Water Displacing Rust Preventative was valued at approximately $1,181 million. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach a revised size of around $1,639 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.8% during the forecast period. The increasing demand for rust prevention solutions across various industries, coupled with advancements in product formulations, is driving this market expansion. As industries continue to prioritize the protection and longevity of their metal assets, the need for effective rust preventative solutions is expected to rise. This growth is further supported by the ongoing development of environmentally friendly and efficient products that meet the evolving needs of consumers and regulatory requirements. The market's positive outlook reflects the critical role that water displacing rust preventatives play in maintaining the integrity and performance of metal components in diverse applications.

| Report Metric | Details |

| Report Name | Water Displacing Rust Preventative Market |

| Accounted market size in year | US$ 1181 million |

| Forecasted market size in 2031 | US$ 1639 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Protection Duration |

|

| Segment by Application Method |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | EXCOR (Germany), DuBois Chemicals (USA), Advanced Fluid Technologies (USA), Daubert Chemical (USA), PLUSCO (USA), Du-Lite (USA), Fluoramics (USA), ITW Pro Brands (USA), FUCHS (Germany), CRC Industries (USA), Hubbard-Hall (USA), Klüber Lubrication (Germany), Chemcoat (USA), Eureka Chemical (USA) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |