What is Global Resorcinol Formaldehyde Adhesive Resin Market?

The Global Resorcinol Formaldehyde Adhesive Resin Market is a specialized segment within the broader adhesive industry, focusing on the production and application of resorcinol formaldehyde resins. These resins are known for their exceptional adhesive properties, particularly in high-stress and high-temperature environments. They are primarily used in industries where strong, durable bonds are essential, such as in the manufacturing of tires, rubber products, and various other industrial applications. The market for these resins is driven by the demand for high-performance adhesives that can withstand harsh conditions and provide long-lasting bonds. The global market is characterized by a steady growth trajectory, fueled by advancements in manufacturing technologies and the increasing need for durable materials in various industrial sectors. As industries continue to evolve and demand more robust materials, the role of resorcinol formaldehyde adhesive resins becomes increasingly significant. This market is also influenced by regulatory standards and environmental considerations, as manufacturers strive to produce resins that are not only effective but also environmentally friendly. Overall, the Global Resorcinol Formaldehyde Adhesive Resin Market represents a critical component of the industrial adhesive landscape, with a focus on innovation and sustainability.

RPF Resin, Modified RPF Resin in the Global Resorcinol Formaldehyde Adhesive Resin Market:

RPF Resin, or Resorcinol-Phenol-Formaldehyde Resin, is a type of adhesive resin that combines the properties of resorcinol, phenol, and formaldehyde to create a highly durable and heat-resistant adhesive. This resin is particularly valued in applications where strong, long-lasting bonds are required, such as in the production of tires and other rubber products. The unique chemical structure of RPF Resin allows it to form strong covalent bonds with various substrates, making it an ideal choice for demanding industrial applications. Modified RPF Resin, on the other hand, refers to variations of the standard RPF Resin that have been chemically altered to enhance specific properties, such as flexibility, curing time, or environmental resistance. These modifications are often made to tailor the resin to specific applications or to meet particular regulatory requirements. In the context of the Global Resorcinol Formaldehyde Adhesive Resin Market, both RPF Resin and Modified RPF Resin play crucial roles. The demand for these resins is driven by their ability to provide reliable performance in challenging conditions, such as high temperatures and exposure to chemicals. Industries that rely on these resins include automotive, construction, and aerospace, where the need for strong, durable adhesives is paramount. The development of Modified RPF Resins has allowed manufacturers to expand the range of applications for these adhesives, offering solutions that are not only effective but also adaptable to changing industry needs. As the market continues to grow, the focus on innovation and customization in RPF Resin formulations is likely to increase, providing new opportunities for manufacturers and end-users alike. The versatility of RPF Resins, combined with their proven performance, makes them a staple in the adhesive industry, with a bright future ahead as industries continue to seek out high-performance bonding solutions.

Tires, Rubber Products, Other in the Global Resorcinol Formaldehyde Adhesive Resin Market:

The Global Resorcinol Formaldehyde Adhesive Resin Market finds extensive usage in several key areas, including tires, rubber products, and other industrial applications. In the tire industry, these resins are used to enhance the bonding between rubber and reinforcing materials, such as steel cords and textile fibers. This is crucial for ensuring the structural integrity and performance of tires, particularly in high-stress environments. The adhesive properties of resorcinol formaldehyde resins help to improve the durability and lifespan of tires, making them a preferred choice for manufacturers seeking to produce high-quality, long-lasting products. In the realm of rubber products, these resins are used to bond various rubber components together, providing strength and resilience to items such as conveyor belts, hoses, and gaskets. The ability of resorcinol formaldehyde resins to withstand harsh conditions, including exposure to chemicals and extreme temperatures, makes them ideal for use in industrial settings where reliability is paramount. Beyond tires and rubber products, the Global Resorcinol Formaldehyde Adhesive Resin Market also serves a variety of other applications. These include the construction industry, where the resins are used in the production of laminated beams and other structural components, as well as in the aerospace and automotive sectors, where strong, lightweight materials are essential. The versatility of these resins allows them to be used in a wide range of applications, providing manufacturers with the flexibility to meet diverse industry needs. As industries continue to evolve and demand more robust materials, the role of resorcinol formaldehyde adhesive resins in providing reliable, high-performance bonding solutions is likely to grow, further solidifying their position in the global market.

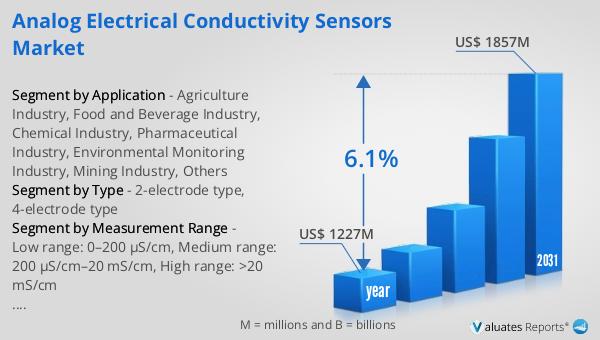

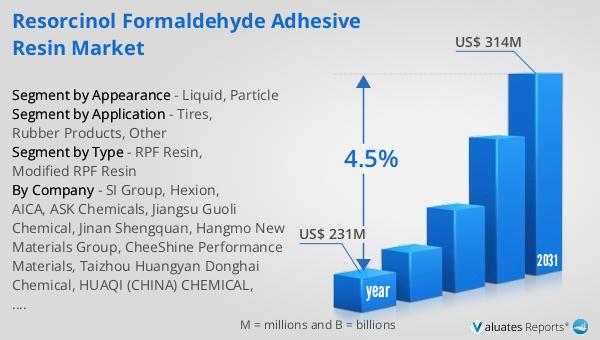

Global Resorcinol Formaldehyde Adhesive Resin Market Outlook:

In 2024, the global market for Resorcinol Formaldehyde Adhesive Resin was valued at approximately $231 million. Looking ahead, this market is expected to grow steadily, reaching an estimated value of $314 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.5% over the forecast period. The expansion of this market can be attributed to several factors, including the increasing demand for high-performance adhesives in various industrial applications. As industries such as automotive, construction, and aerospace continue to seek out materials that offer superior bonding capabilities and durability, the demand for resorcinol formaldehyde adhesive resins is likely to rise. Additionally, advancements in manufacturing technologies and the development of modified resin formulations are expected to contribute to market growth by providing more tailored solutions to meet specific industry needs. The market's growth is also influenced by regulatory standards and environmental considerations, as manufacturers strive to produce resins that are not only effective but also environmentally friendly. Overall, the Global Resorcinol Formaldehyde Adhesive Resin Market is poised for steady growth, driven by the ongoing demand for high-performance adhesives and the continuous evolution of industrial requirements.

| Report Metric | Details |

| Report Name | Resorcinol Formaldehyde Adhesive Resin Market |

| Accounted market size in year | US$ 231 million |

| Forecasted market size in 2031 | US$ 314 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Appearance |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SI Group, Hexion, AICA, ASK Chemicals, Jiangsu Guoli Chemical, Jinan Shengquan, Hangmo New Materials Group, CheeShine Performance Materials, Taizhou Huangyan Donghai Chemical, HUAQI (CHINA) CHEMICAL, Wuhan Jinghe Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |