What is Global Phenolic Resin for Fiberglass Market?

The Global Phenolic Resin for Fiberglass Market is a specialized segment within the broader chemical and materials industry, focusing on the production and application of phenolic resins specifically designed for use with fiberglass. Phenolic resins are synthetic polymers obtained by the reaction of phenol or substituted phenol with formaldehyde. These resins are known for their excellent thermal stability, mechanical strength, and resistance to chemicals and fire, making them ideal for reinforcing fiberglass. Fiberglass, a material made from extremely fine fibers of glass, is widely used in various industries due to its lightweight, high strength, and versatility. When combined with phenolic resin, fiberglass becomes even more robust and durable, suitable for demanding applications. The market for phenolic resin for fiberglass is driven by the increasing demand for lightweight and high-performance materials in industries such as automotive, construction, aerospace, and electronics. As these industries continue to evolve and seek materials that offer better performance and sustainability, the demand for phenolic resin for fiberglass is expected to grow. This market is characterized by continuous innovation and development, with manufacturers focusing on enhancing the properties of phenolic resins to meet the specific needs of different applications.

Solid Content ≥50%, Solid Content ≥65%, Solid Content ≥75%, Other in the Global Phenolic Resin for Fiberglass Market:

In the Global Phenolic Resin for Fiberglass Market, the solid content of the resin is a critical factor that determines its performance and suitability for various applications. Solid content refers to the percentage of non-volatile matter present in the resin, which directly impacts its viscosity, curing time, and final properties. Resins with different solid content levels are used to meet specific requirements in different industries. Solid Content ≥50% refers to phenolic resins that contain at least 50% non-volatile matter. These resins are typically used in applications where a balance between performance and cost is required. They offer good mechanical properties and are suitable for general-purpose applications in industries such as construction and automotive. Solid Content ≥65% resins have a higher concentration of non-volatile matter, providing enhanced mechanical strength and thermal stability. These resins are often used in more demanding applications where higher performance is required, such as in the aerospace and defense industries. Solid Content ≥75% resins represent the highest concentration of non-volatile matter, offering superior performance characteristics. These resins are used in critical applications where maximum strength, durability, and resistance to extreme conditions are essential. They are commonly used in the production of high-performance composites for the aerospace, marine, and industrial sectors. Other solid content levels may also be available, tailored to meet specific customer requirements or niche applications. Manufacturers continuously innovate to develop resins with optimized solid content levels, balancing performance, cost, and processing characteristics to meet the evolving needs of the market. The choice of solid content level depends on various factors, including the intended application, processing methods, and desired properties of the final product. As industries continue to demand materials that offer better performance and sustainability, the development and use of phenolic resins with varying solid content levels are expected to grow, driving innovation and growth in the Global Phenolic Resin for Fiberglass Market.

Rail Transportation, Aerospace, Industrial Equipment, Electrical and Electronic, Other in the Global Phenolic Resin for Fiberglass Market:

The Global Phenolic Resin for Fiberglass Market finds extensive usage across various industries due to the unique properties of phenolic resins, which enhance the performance of fiberglass. In rail transportation, phenolic resins are used to produce lightweight and durable components that can withstand the rigors of daily use. The high thermal stability and fire resistance of phenolic resins make them ideal for use in train interiors, where safety is a paramount concern. Components such as seats, panels, and flooring benefit from the enhanced strength and durability provided by phenolic resins, contributing to the overall safety and efficiency of rail systems. In the aerospace industry, phenolic resins are used to manufacture high-performance composites that are essential for aircraft construction. The lightweight nature of fiberglass reinforced with phenolic resin helps reduce the overall weight of aircraft, leading to improved fuel efficiency and reduced emissions. Additionally, the excellent thermal and chemical resistance of phenolic resins ensures that aerospace components can withstand extreme conditions, enhancing the safety and reliability of aircraft. In the industrial equipment sector, phenolic resins are used to produce components that require high mechanical strength and resistance to harsh environments. Equipment such as pumps, valves, and tanks benefit from the enhanced durability and chemical resistance provided by phenolic resins, ensuring long-lasting performance in demanding industrial applications. In the electrical and electronic industry, phenolic resins are used to produce insulating materials and components that require high thermal stability and electrical resistance. Applications such as circuit boards, connectors, and housings benefit from the enhanced properties of phenolic resins, ensuring reliable performance in electronic devices. Other industries also benefit from the unique properties of phenolic resins for fiberglass, with applications ranging from construction to marine and beyond. As industries continue to seek materials that offer better performance, safety, and sustainability, the usage of phenolic resins for fiberglass is expected to grow, driving innovation and development in the Global Phenolic Resin for Fiberglass Market.

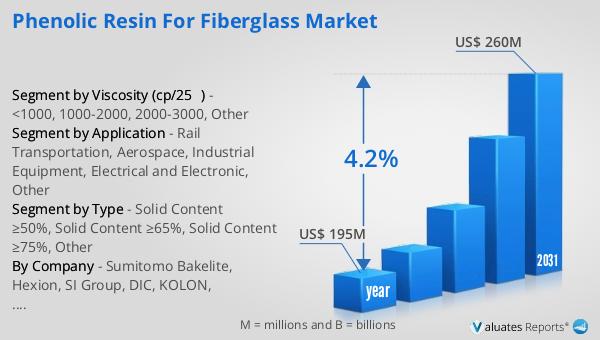

Global Phenolic Resin for Fiberglass Market Outlook:

The global market for Phenolic Resin for Fiberglass was valued at $195 million in 2024 and is anticipated to expand to a revised size of $260 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.2% over the forecast period. This growth trajectory underscores the increasing demand for phenolic resin in various applications, driven by its superior properties such as thermal stability, mechanical strength, and resistance to chemicals and fire. The market's expansion is fueled by the rising need for lightweight and high-performance materials across industries like automotive, aerospace, and construction. As these sectors continue to evolve, the demand for materials that offer enhanced performance and sustainability is expected to rise, further propelling the growth of the phenolic resin for fiberglass market. The projected growth also highlights the ongoing innovation and development within the industry, as manufacturers strive to enhance the properties of phenolic resins to meet the specific needs of different applications. This market outlook reflects the dynamic nature of the industry and the opportunities for growth and development in the coming years.

| Report Metric | Details |

| Report Name | Phenolic Resin for Fiberglass Market |

| Accounted market size in year | US$ 195 million |

| Forecasted market size in 2031 | US$ 260 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Viscosity (cp/25℃) |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sumitomo Bakelite, Hexion, SI Group, DIC, KOLON, Shengquan Group, Shandong Tiancheng Chemical, Suzhou Xingye Materials Technology, Willing New Materials, SenBo New Materials (Jiangsu) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |