What is Global SIC Wafer Grinding Wheel Market?

The Global SIC Wafer Grinding Wheel Market is a specialized segment within the broader industrial tools and equipment industry, focusing on the production and distribution of grinding wheels specifically designed for silicon carbide (SIC) wafers. These wafers are critical components in the manufacturing of semiconductors, which are essential for a wide range of electronic devices. The market for SIC wafer grinding wheels is driven by the increasing demand for semiconductors, which are used in everything from smartphones and computers to automotive electronics and renewable energy technologies. As technology advances, the need for more efficient and precise grinding solutions has grown, leading to innovations in grinding wheel materials and designs. The market is characterized by a diverse range of products, including vitrified, resin, and ceramic bonded grinding wheels, each offering unique benefits and applications. Companies operating in this market are continually investing in research and development to enhance the performance and durability of their products, aiming to meet the evolving needs of the semiconductor industry. The global reach of this market is expanding, with significant growth opportunities in regions with burgeoning electronics manufacturing sectors.

Vitrified Bonded Grinding Wheels, Resin Bonded Grinding Wheels, Ceramic Bonded Grinding Wheels in the Global SIC Wafer Grinding Wheel Market:

Vitrified bonded grinding wheels are a key component in the Global SIC Wafer Grinding Wheel Market, known for their durability and precision. These wheels are made by fusing abrasive grains with a vitrified bond, which is a type of glass-like material. This bond provides the wheels with a high level of hardness and strength, making them ideal for applications that require precise and consistent grinding. Vitrified bonded grinding wheels are particularly effective in maintaining their shape and sharpness over time, which is crucial for the high-precision demands of semiconductor manufacturing. They are often used in applications where a high degree of accuracy is required, such as in the finishing of SIC wafers. The ability of these wheels to operate at high speeds without losing their structural integrity makes them a preferred choice for many manufacturers. Resin bonded grinding wheels, on the other hand, are known for their versatility and cost-effectiveness. These wheels use a resin, typically a synthetic polymer, as the bonding agent. This type of bond allows for a degree of flexibility, which can be advantageous in certain grinding applications. Resin bonded wheels are often used in situations where a smoother finish is desired, as the resin bond can help to reduce the amount of heat generated during the grinding process. This can be particularly beneficial when working with materials that are sensitive to heat, such as certain types of SIC wafers. Additionally, resin bonded wheels are generally easier to produce and can be more cost-effective than their vitrified counterparts, making them an attractive option for manufacturers looking to balance performance with budget considerations. Ceramic bonded grinding wheels represent another important segment of the Global SIC Wafer Grinding Wheel Market. These wheels use a ceramic material as the bonding agent, which provides a unique set of properties. Ceramic bonds are known for their ability to withstand high temperatures and pressures, making them ideal for demanding grinding applications. The use of ceramic bonds can also enhance the cutting efficiency of the grinding wheel, allowing for faster material removal rates. This can be particularly advantageous in high-volume manufacturing environments where time is of the essence. Furthermore, ceramic bonded grinding wheels often exhibit excellent wear resistance, which can lead to longer tool life and reduced downtime for maintenance. This can result in significant cost savings for manufacturers over the long term. Each type of grinding wheel offers distinct advantages and is suited to different applications within the SIC wafer grinding process. The choice of which type to use often depends on the specific requirements of the application, such as the desired finish, the material being worked on, and the production volume. As the Global SIC Wafer Grinding Wheel Market continues to evolve, manufacturers are likely to see further innovations in bonding materials and techniques, leading to even more efficient and effective grinding solutions.

Precision Optics, Semiconductor, Others in the Global SIC Wafer Grinding Wheel Market:

The Global SIC Wafer Grinding Wheel Market plays a crucial role in several key industries, including precision optics, semiconductors, and others. In the field of precision optics, SIC wafer grinding wheels are used to achieve the high levels of accuracy and surface finish required for optical components. These components, such as lenses and mirrors, are used in a wide range of applications, from cameras and telescopes to medical imaging devices. The ability of SIC wafer grinding wheels to produce smooth, precise surfaces makes them an essential tool in the production of high-quality optical components. The semiconductor industry is another major user of SIC wafer grinding wheels. Semiconductors are the building blocks of modern electronics, and their production requires extremely precise and consistent grinding processes. SIC wafer grinding wheels are used to shape and finish the wafers that form the basis of semiconductor devices. The high level of precision offered by these grinding wheels is essential for ensuring the performance and reliability of the final products. In addition to precision optics and semiconductors, SIC wafer grinding wheels are also used in a variety of other industries. For example, they are used in the production of advanced ceramics, which are used in applications ranging from aerospace to medical devices. The ability of SIC wafer grinding wheels to produce precise, high-quality surfaces makes them an invaluable tool in the production of these advanced materials. The versatility and precision of SIC wafer grinding wheels make them an essential component in a wide range of industries. As technology continues to advance, the demand for high-quality grinding solutions is likely to grow, driving further innovation and development in the Global SIC Wafer Grinding Wheel Market.

Global SIC Wafer Grinding Wheel Market Outlook:

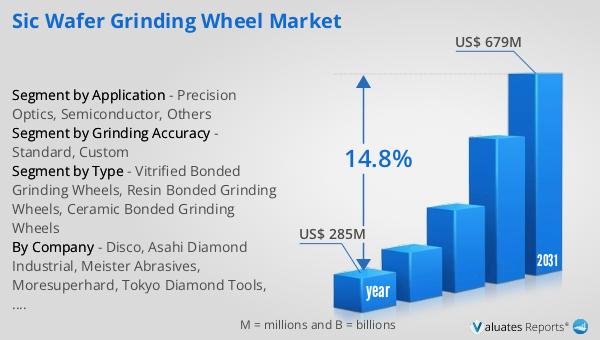

The global market for SIC Wafer Grinding Wheels was valued at approximately $285 million in 2024, and it is anticipated to grow significantly over the coming years. By 2031, the market is expected to reach a revised size of around $679 million, reflecting a robust compound annual growth rate (CAGR) of 14.8% during the forecast period. This impressive growth rate underscores the increasing demand for SIC wafer grinding wheels, driven by the expanding semiconductor industry and the need for more efficient and precise grinding solutions. The projected CAGR of 14.8% over the next five years highlights the dynamic nature of this market and the opportunities for growth and innovation. As the demand for semiconductors continues to rise, fueled by advancements in technology and the proliferation of electronic devices, the need for high-quality SIC wafer grinding wheels is expected to grow in tandem. This growth presents significant opportunities for companies operating in this market to expand their product offerings and enhance their competitive position. The global reach of the SIC Wafer Grinding Wheel Market is also expanding, with increasing demand from regions with burgeoning electronics manufacturing sectors. As a result, companies are investing in research and development to create more efficient and durable grinding solutions that can meet the evolving needs of the semiconductor industry. The future of the Global SIC Wafer Grinding Wheel Market looks promising, with continued growth and innovation on the horizon.

| Report Metric | Details |

| Report Name | SIC Wafer Grinding Wheel Market |

| Accounted market size in year | US$ 285 million |

| Forecasted market size in 2031 | US$ 679 million |

| CAGR | 14.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Grinding Accuracy |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Disco, Asahi Diamond Industrial, Meister Abrasives, Moresuperhard, Tokyo Diamond Tools, A.L.M.T. Corp (Sumitomo Electric), Tokyo Seimitsu, Saint-Gobain, EHWA DIAMOND, OKAMOTO MACHINE TOOL WORKS, Zhengzhou Qisheng Precision Manufacturing, Carbo Tzujan Industry, KINIK COMPANY, China National Machinery Industry Corporation, Henan Keen Super-hard Material Technology, Dongguan Zhongwei Lihe Semiconductor Technology, Zhengzhou Abrasive and Grinding Tool Research Institute, NanJing Sanchao Advanced Materials, Suzhou Sail Science & Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |