What is Global Single-use Bioprocessing Systems Market?

The Global Single-use Bioprocessing Systems Market is a rapidly evolving sector within the biotechnology and pharmaceutical industries. These systems are designed for one-time use, which eliminates the need for cleaning and sterilization, thus reducing the risk of contamination and saving time. They are primarily used in the production of biopharmaceuticals, including vaccines, monoclonal antibodies, and other therapeutic proteins. The market is driven by the increasing demand for biopharmaceuticals, which require flexible and efficient manufacturing processes. Single-use systems offer several advantages over traditional stainless-steel systems, such as lower capital investment, reduced operational costs, and increased flexibility in production. These benefits make them particularly attractive to small and medium-sized enterprises and contract development and manufacturing organizations (CDMOs) that need to adapt quickly to changing market demands. Additionally, the growing focus on personalized medicine and the need for rapid production of small batches of drugs further fuel the adoption of single-use bioprocessing systems. As a result, the market is expected to continue its growth trajectory, driven by technological advancements and the increasing adoption of single-use technologies in biopharmaceutical manufacturing.

Single-use Bioreactors, Disposable Sterile Bags, Disposable Filtration Systems, Others in the Global Single-use Bioprocessing Systems Market:

Single-use bioreactors are a cornerstone of the Global Single-use Bioprocessing Systems Market. These bioreactors are designed for one-time use and are typically made from plastic materials. They offer several advantages over traditional stainless-steel bioreactors, including reduced risk of cross-contamination, lower capital investment, and increased flexibility in production. Single-use bioreactors are widely used in the production of biopharmaceuticals, including vaccines, monoclonal antibodies, and other therapeutic proteins. They are particularly beneficial for small and medium-sized enterprises and contract development and manufacturing organizations (CDMOs) that need to adapt quickly to changing market demands. Disposable sterile bags are another critical component of the single-use bioprocessing systems market. These bags are used for the storage and transportation of biopharmaceutical products and intermediates. They are designed to be used once and then discarded, which eliminates the need for cleaning and sterilization. This reduces the risk of contamination and saves time, making them an attractive option for biopharmaceutical manufacturers. Disposable filtration systems are also an essential part of the single-use bioprocessing systems market. These systems are used to remove impurities and contaminants from biopharmaceutical products. They are designed for one-time use, which eliminates the need for cleaning and sterilization and reduces the risk of contamination. Other components of the single-use bioprocessing systems market include disposable connectors, tubing, and sensors. These components are designed to be used once and then discarded, which reduces the risk of contamination and saves time. The increasing demand for biopharmaceuticals, coupled with the need for flexible and efficient manufacturing processes, is driving the growth of the single-use bioprocessing systems market. Technological advancements and the growing adoption of single-use technologies in biopharmaceutical manufacturing are expected to further fuel the market's growth.

Bio-pharmacy, CDMO, Others in the Global Single-use Bioprocessing Systems Market:

The Global Single-use Bioprocessing Systems Market plays a crucial role in various areas, including bio-pharmacy, contract development and manufacturing organizations (CDMOs), and other sectors. In bio-pharmacy, single-use systems are widely used for the production of biopharmaceuticals, including vaccines, monoclonal antibodies, and other therapeutic proteins. These systems offer several advantages over traditional stainless-steel systems, such as lower capital investment, reduced operational costs, and increased flexibility in production. This makes them particularly attractive to small and medium-sized enterprises that need to adapt quickly to changing market demands. In the CDMO sector, single-use bioprocessing systems are used to provide flexible and efficient manufacturing solutions for biopharmaceutical companies. CDMOs are increasingly adopting single-use technologies to meet the growing demand for biopharmaceuticals and to provide rapid production of small batches of drugs. The use of single-use systems allows CDMOs to reduce the risk of contamination, lower operational costs, and increase production flexibility. Other sectors that benefit from single-use bioprocessing systems include academic and research institutions, which use these systems for research and development purposes. The growing focus on personalized medicine and the need for rapid production of small batches of drugs further fuel the adoption of single-use bioprocessing systems in these sectors. Overall, the Global Single-use Bioprocessing Systems Market is expected to continue its growth trajectory, driven by technological advancements and the increasing adoption of single-use technologies in biopharmaceutical manufacturing.

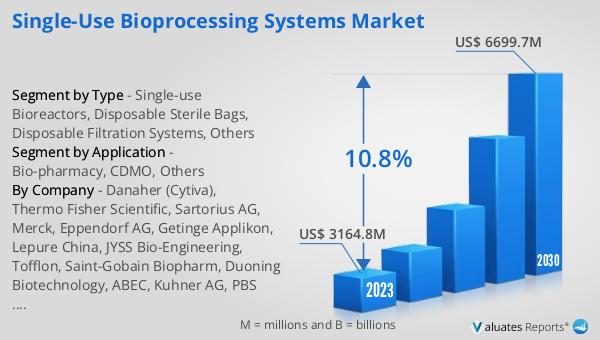

Global Single-use Bioprocessing Systems Market Outlook:

In 2024, the global market for Single-use Bioprocessing Systems was valued at approximately $3,973 million. By 2031, it is anticipated to expand significantly, reaching an estimated value of $8,065 million. This growth represents a compound annual growth rate (CAGR) of 10.8% over the forecast period. The market's expansion is driven by several factors, including the increasing demand for biopharmaceuticals, the need for flexible and efficient manufacturing processes, and the growing adoption of single-use technologies in biopharmaceutical manufacturing. Single-use bioprocessing systems offer several advantages over traditional stainless-steel systems, such as lower capital investment, reduced operational costs, and increased flexibility in production. These benefits make them particularly attractive to small and medium-sized enterprises and contract development and manufacturing organizations (CDMOs) that need to adapt quickly to changing market demands. Additionally, the growing focus on personalized medicine and the need for rapid production of small batches of drugs further fuel the adoption of single-use bioprocessing systems. As a result, the market is expected to continue its growth trajectory, driven by technological advancements and the increasing adoption of single-use technologies in biopharmaceutical manufacturing.

| Report Metric | Details |

| Report Name | Single-use Bioprocessing Systems Market |

| Accounted market size in year | US$ 3973 million |

| Forecasted market size in 2031 | US$ 8065 million |

| CAGR | 10.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Danaher (Cytiva), Thermo Fisher Scientific, Sartorius AG, Merck, Eppendorf AG, Getinge Applikon, Lepure China, JYSS Bio-Engineering, Tofflon, Saint-Gobain Biopharm, Duoning Biotechnology, ABEC, Kuhner AG, PBS Biotech, Cell-tainer Biotech BV, Meissner Filtration Products, AUSTAR, SATAKE MultiMix |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |