What is Global CNC Vertical Machining Center Market?

The Global CNC Vertical Machining Center Market is a dynamic and rapidly evolving sector within the manufacturing industry. CNC, which stands for Computer Numerical Control, refers to the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands. Vertical Machining Centers (VMCs) are a type of CNC machine where the spindle axis is vertically oriented. These machines are essential for producing precision parts and components across various industries. The global market for CNC Vertical Machining Centers is driven by the increasing demand for high-speed, high-precision machining solutions. Industries such as aerospace, automotive, electronics, and healthcare rely heavily on these machines for their manufacturing processes. The market is characterized by technological advancements, with manufacturers continuously innovating to improve machine efficiency, accuracy, and versatility. As industries strive for greater productivity and cost-effectiveness, the adoption of CNC Vertical Machining Centers is expected to grow, making it a crucial component of modern manufacturing. The market's growth is also supported by the rising trend of automation and the need for complex machining operations, which these centers can efficiently handle. Overall, the Global CNC Vertical Machining Center Market plays a vital role in enhancing manufacturing capabilities and meeting the demands of various sectors.

2-Axis CNC Machine, 3-Axis CNC Machine, 4-Axis CNC Machine, 5-Axis CNC Machine in the Global CNC Vertical Machining Center Market:

In the realm of CNC machining, the number of axes a machine operates on significantly influences its capabilities and applications. A 2-Axis CNC Machine is the most basic form, typically involving two linear axes, X and Y, which allow for simple cutting and drilling operations. These machines are often used for straightforward tasks such as cutting flat surfaces or creating holes in a workpiece. While limited in complexity, they are cost-effective and suitable for small-scale operations or educational purposes where basic CNC skills are taught. Moving up in complexity, the 3-Axis CNC Machine introduces a third axis, the Z-axis, which adds vertical movement to the machine's capabilities. This allows for more intricate operations such as milling, drilling, and tapping on three-dimensional surfaces. The 3-axis machines are widely used in industries like automotive and electronics for producing parts with moderate complexity. They offer a balance between cost and functionality, making them a popular choice for many manufacturers. The 4-Axis CNC Machine takes it a step further by adding a rotational axis, often referred to as the A-axis, which allows the workpiece to be rotated around one of the linear axes. This additional axis enables the machine to perform more complex operations, such as creating intricate geometries and features that require multiple angles of approach. The 4-axis machines are particularly useful in industries like aerospace and defense, where precision and complexity are paramount. Finally, the 5-Axis CNC Machine represents the pinnacle of CNC machining technology, incorporating two rotational axes in addition to the three linear axes. This configuration allows for the machining of highly complex and intricate parts with minimal repositioning of the workpiece. The 5-axis machines are essential in industries that demand the highest levels of precision and complexity, such as aerospace, medical device manufacturing, and high-end automotive production. They enable the creation of parts with intricate geometries and tight tolerances, reducing the need for multiple setups and manual intervention. The versatility and efficiency of 5-axis machines make them a valuable asset for manufacturers looking to stay competitive in today's fast-paced market. As the Global CNC Vertical Machining Center Market continues to evolve, the demand for machines with higher axes is expected to grow, driven by the need for greater precision, efficiency, and versatility in manufacturing processes.

Aerospace and Defense, Automobile, Electronics, Healthcare, Industrial Machinery, Other Industries in the Global CNC Vertical Machining Center Market:

The Global CNC Vertical Machining Center Market finds extensive applications across a wide range of industries, each with its unique set of requirements and challenges. In the aerospace and defense sector, these machining centers are indispensable for producing high-precision components such as turbine blades, engine parts, and structural components. The ability to machine complex geometries with tight tolerances is crucial in this industry, where safety and performance are paramount. CNC Vertical Machining Centers enable manufacturers to meet these stringent requirements while maintaining efficiency and cost-effectiveness. In the automotive industry, these machines are used to produce a variety of components, including engine blocks, transmission cases, and suspension parts. The demand for lightweight and high-performance vehicles drives the need for precision machining, making CNC Vertical Machining Centers an essential tool for automotive manufacturers. The electronics industry also benefits from these machines, as they are used to produce intricate components such as circuit boards, connectors, and enclosures. The miniaturization of electronic devices requires high-precision machining capabilities, which CNC Vertical Machining Centers can provide. In the healthcare sector, these machines are used to manufacture medical devices and implants, where precision and quality are critical. The ability to produce complex shapes and features with high accuracy is essential for ensuring the safety and effectiveness of medical products. Industrial machinery manufacturers also rely on CNC Vertical Machining Centers to produce components for various types of equipment, from construction machinery to food processing equipment. The versatility and efficiency of these machines make them suitable for a wide range of applications, allowing manufacturers to meet the diverse needs of their customers. Other industries, such as energy, marine, and consumer goods, also utilize CNC Vertical Machining Centers for their manufacturing processes. The ability to produce high-quality components with precision and efficiency makes these machines a valuable asset across multiple sectors. As the demand for complex and high-performance products continues to grow, the Global CNC Vertical Machining Center Market is expected to play a crucial role in meeting the evolving needs of various industries.

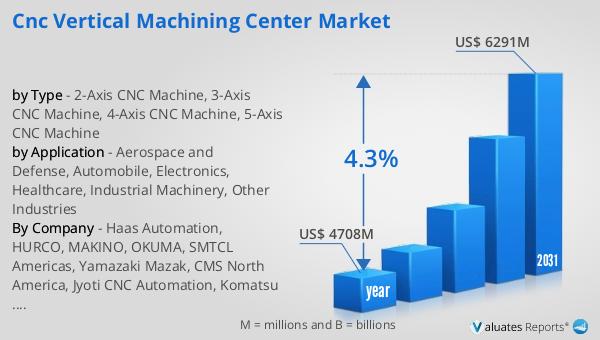

Global CNC Vertical Machining Center Market Outlook:

The global market for CNC Vertical Machining Centers was valued at approximately $4,708 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $6,291 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.3% over the forecast period. The increasing demand for precision machining solutions across various industries is a key driver of this growth. As manufacturers strive to enhance productivity and reduce operational costs, the adoption of CNC Vertical Machining Centers is expected to rise. These machines offer the ability to perform complex machining operations with high precision and efficiency, making them an attractive investment for companies looking to stay competitive in the global market. The market's expansion is also supported by technological advancements, with manufacturers continuously innovating to improve machine capabilities and performance. As industries such as aerospace, automotive, electronics, and healthcare continue to evolve, the demand for CNC Vertical Machining Centers is expected to grow, driving the market's overall growth. The projected increase in market size reflects the growing importance of these machines in modern manufacturing processes and their role in meeting the demands of various sectors.

| Report Metric | Details |

| Report Name | CNC Vertical Machining Center Market |

| Accounted market size in year | US$ 4708 million |

| Forecasted market size in 2031 | US$ 6291 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Haas Automation, HURCO, MAKINO, OKUMA, SMTCL Americas, Yamazaki Mazak, CMS North America, Jyoti CNC Automation, Komatsu NTC, KRUDO Industrial, Mitsubishi Electric, DMG MORI, BFW |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |