What is Global Material Jetting (MJ) Equipment Market?

The Global Material Jetting (MJ) Equipment Market is a rapidly evolving sector within the broader field of additive manufacturing, commonly known as 3D printing. Material jetting is a process where droplets of material are deposited layer by layer to create a three-dimensional object. This technology is highly valued for its precision and ability to produce complex geometries with fine details. The market for MJ equipment is driven by its applications across various industries, including medical, automotive, and jewelry, among others. As industries continue to seek efficient and cost-effective manufacturing solutions, the demand for material jetting technology is expected to grow. The versatility of MJ equipment allows for the use of multiple materials, including metals, plastics, and ceramics, which broadens its applicability. Furthermore, advancements in technology are enhancing the speed, accuracy, and material compatibility of MJ equipment, making it an attractive option for manufacturers looking to innovate and streamline their production processes. As a result, the Global Material Jetting Equipment Market is poised for significant growth, driven by technological advancements and increasing adoption across diverse industries.

Ink Jetting, Binder Jetting, Aerosol Jetting in the Global Material Jetting (MJ) Equipment Market:

Material jetting encompasses several techniques, including ink jetting, binder jetting, and aerosol jetting, each with unique characteristics and applications. Ink jetting is a process where liquid photopolymers are jetted onto a build platform and cured using ultraviolet light. This method is renowned for its high resolution and ability to produce smooth surfaces, making it ideal for applications requiring fine detail and precision, such as in the creation of prototypes and intricate models. Ink jetting is particularly popular in industries like jewelry and dental, where the aesthetic quality of the final product is paramount. Binder jetting, on the other hand, involves the deposition of a liquid binding agent onto a powder bed, layer by layer, to form a solid part. This technique is advantageous for its ability to work with a wide range of materials, including metals, ceramics, and sand. Binder jetting is often used in the production of metal parts and molds, offering a cost-effective alternative to traditional manufacturing methods. It is particularly beneficial in the automotive and aerospace industries, where the production of lightweight and complex components is essential. Aerosol jetting is a more specialized form of material jetting, where an aerosolized material is deposited onto a substrate. This technique is used for creating fine features and is particularly useful in the electronics industry for printing conductive traces and components on circuit boards. Aerosol jetting allows for the deposition of a wide range of materials, including conductive inks and polymers, enabling the production of flexible and lightweight electronic devices. Each of these material jetting techniques offers distinct advantages and is suited to specific applications, contributing to the overall growth and diversification of the Global Material Jetting Equipment Market. As industries continue to explore the potential of additive manufacturing, the demand for these technologies is expected to rise, driven by the need for innovative and efficient production solutions.

Medical Industry, Jewelry Industry, Industrial Tools, Automotive Industry, Others in the Global Material Jetting (MJ) Equipment Market:

The Global Material Jetting (MJ) Equipment Market finds extensive usage across various industries, each leveraging the unique capabilities of this technology to enhance their manufacturing processes. In the medical industry, material jetting is used to create highly detailed and accurate models for surgical planning and training. The ability to produce patient-specific models and implants with high precision is revolutionizing the field of personalized medicine. Material jetting also plays a crucial role in the production of dental prosthetics, where the demand for custom-fit and aesthetically pleasing products is high. In the jewelry industry, material jetting is used to create intricate designs and prototypes with exceptional detail and surface finish. The technology allows for the rapid production of custom jewelry pieces, reducing lead times and enabling designers to bring their creations to market faster. Industrial tools and components benefit from material jetting's ability to produce complex geometries and lightweight structures. The technology is used to create molds, jigs, and fixtures, streamlining the manufacturing process and reducing costs. In the automotive industry, material jetting is used to produce lightweight components and prototypes, enabling manufacturers to test and refine designs before mass production. The ability to create complex parts with minimal material waste is particularly advantageous in this sector, where efficiency and sustainability are key considerations. Beyond these industries, material jetting is also used in the production of consumer goods, electronics, and architectural models, among others. The versatility and precision of material jetting make it an attractive option for manufacturers looking to innovate and improve their production processes. As the technology continues to evolve, its applications are expected to expand, driving further growth in the Global Material Jetting Equipment Market.

Global Material Jetting (MJ) Equipment Market Outlook:

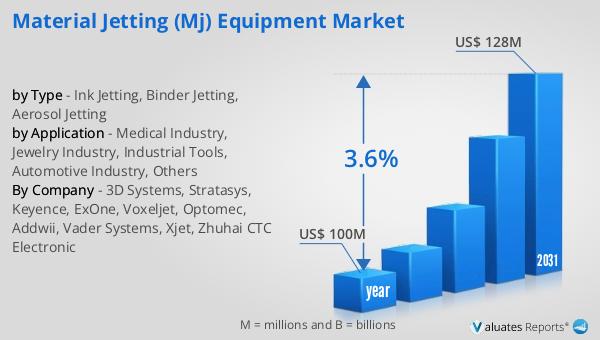

The global market for Material Jetting (MJ) Equipment was valued at $100 million in 2024 and is anticipated to grow to a revised size of $128 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.6% over the forecast period. This growth trajectory underscores the increasing adoption of material jetting technology across various industries, driven by its ability to produce high-quality, complex parts with precision and efficiency. The market's expansion is fueled by advancements in technology that enhance the capabilities of MJ equipment, making it more versatile and accessible to a broader range of applications. As industries continue to seek innovative manufacturing solutions, the demand for material jetting equipment is expected to rise, contributing to the market's growth. The projected increase in market size reflects the growing recognition of material jetting as a viable and cost-effective alternative to traditional manufacturing methods. As the technology continues to evolve, it is likely to play an increasingly important role in the future of manufacturing, offering new opportunities for innovation and efficiency. The steady growth of the Global Material Jetting Equipment Market highlights the potential of this technology to transform industries and drive advancements in manufacturing processes.

| Report Metric | Details |

| Report Name | Material Jetting (MJ) Equipment Market |

| Accounted market size in year | US$ 100 million |

| Forecasted market size in 2031 | US$ 128 million |

| CAGR | 3.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | 3D Systems, Stratasys, Keyence, ExOne, Voxeljet, Optomec, Addwii, Vader Systems, Xjet, Zhuhai CTC Electronic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |