What is Global Intermediate Bulk Containers Market?

The Global Intermediate Bulk Containers (IBC) Market is a significant segment within the packaging industry, focusing on the production and distribution of containers designed for the storage and transportation of bulk liquids and granulated substances. These containers are typically made from materials such as plastic, metal, or a combination of both, and are designed to be durable, reusable, and efficient for handling large quantities of materials. The market for IBCs is driven by the need for cost-effective and efficient packaging solutions that can handle the demands of various industries, including chemicals, food and beverages, pharmaceuticals, and agriculture. The versatility of IBCs, which can be used for both hazardous and non-hazardous materials, makes them an attractive option for businesses looking to optimize their supply chain operations. Additionally, the growing emphasis on sustainability and reducing environmental impact has led to increased adoption of IBCs, as they are often designed to be recyclable and reduce waste compared to traditional packaging methods. As industries continue to expand and global trade increases, the demand for IBCs is expected to grow, making it a vital component of the global packaging market.

Rigid Containers, Flexible Bulk Containers in the Global Intermediate Bulk Containers Market:

Rigid Containers and Flexible Bulk Containers are two primary types of Intermediate Bulk Containers (IBCs) that serve distinct purposes within the global market. Rigid Containers, often made from high-density polyethylene (HDPE), metal, or a combination of materials, are designed to provide robust protection for the contents they hold. These containers are typically used for transporting and storing liquids, chemicals, and other materials that require a stable and secure environment. The rigid structure of these containers ensures that they can withstand significant pressure and impact, making them ideal for industries where safety and durability are paramount. Additionally, Rigid Containers are often stackable, which maximizes storage efficiency and reduces transportation costs. They are also designed to be reusable, which aligns with the growing trend towards sustainable packaging solutions. On the other hand, Flexible Bulk Containers, commonly known as FIBCs or bulk bags, are made from woven polypropylene or similar materials. These containers are lightweight, collapsible, and highly versatile, making them suitable for transporting dry bulk materials such as grains, powders, and minerals. The flexibility of these containers allows them to be easily folded and stored when not in use, saving space and reducing logistical costs. Flexible Bulk Containers are also customizable, with options for different sizes, shapes, and features such as liners or coatings to protect the contents from moisture or contamination. This adaptability makes them a popular choice for industries that require specific packaging solutions tailored to their unique needs. Both Rigid and Flexible Bulk Containers play a crucial role in the global IBC market, offering diverse solutions for businesses looking to optimize their packaging and transportation processes. As industries continue to evolve and demand more efficient and sustainable packaging options, the importance of these containers is expected to grow, driving innovation and development within the market.

Food & Beverages, Construction, Healthcare, Fertilizers, Chemical, Minerals in the Global Intermediate Bulk Containers Market:

The usage of Global Intermediate Bulk Containers (IBCs) spans across various industries, each with its unique requirements and challenges. In the Food & Beverages sector, IBCs are essential for the safe and efficient transportation of liquid and granulated food products. These containers ensure that the contents are protected from contamination and spoilage, maintaining the quality and safety of the food items. The ability to handle large volumes of products also makes IBCs a cost-effective solution for food manufacturers and distributors. In the Construction industry, IBCs are used to transport and store materials such as cement, sand, and other construction aggregates. The durability and strength of these containers make them ideal for handling heavy and abrasive materials, ensuring that they can withstand the rigors of construction sites. In the Healthcare sector, IBCs are utilized for the safe transportation of pharmaceuticals and medical supplies. The secure and hygienic design of these containers ensures that sensitive medical products are protected from contamination and damage during transit. In the Fertilizers industry, IBCs are used to store and transport various types of fertilizers, ensuring that they remain dry and free from contamination. The ability to handle large quantities of fertilizers also makes IBCs a practical solution for agricultural businesses. In the Chemical industry, IBCs are crucial for the safe handling and transportation of hazardous and non-hazardous chemicals. The robust design of these containers ensures that they can withstand the corrosive nature of certain chemicals, providing a secure and reliable packaging solution. Lastly, in the Minerals industry, IBCs are used to transport and store minerals and ores, ensuring that they are protected from moisture and contamination. The versatility and durability of IBCs make them an indispensable tool for businesses across these industries, providing a reliable and efficient solution for their packaging and transportation needs.

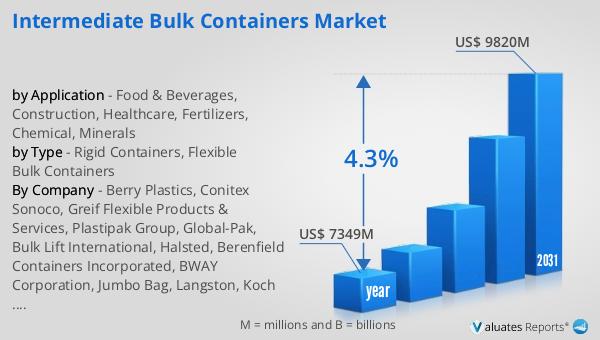

Global Intermediate Bulk Containers Market Outlook:

The global market for Intermediate Bulk Containers (IBCs) has shown significant growth over the years, with its value reaching approximately US$ 7,349 million in 2024. This market is projected to expand further, reaching an estimated size of US$ 9,820 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.3% during the forecast period. The increasing demand for efficient and sustainable packaging solutions across various industries is a key driver of this growth. As businesses continue to seek ways to optimize their supply chain operations and reduce environmental impact, the adoption of IBCs is expected to rise. The versatility and durability of these containers make them an attractive option for industries ranging from chemicals and pharmaceuticals to food and beverages. Additionally, the growing emphasis on sustainability and reducing waste has led to increased interest in reusable and recyclable packaging solutions, further boosting the demand for IBCs. As the market continues to evolve, manufacturers are likely to focus on innovation and development to meet the changing needs of their customers, ensuring that IBCs remain a vital component of the global packaging industry.

| Report Metric | Details |

| Report Name | Intermediate Bulk Containers Market |

| Accounted market size in year | US$ 7349 million |

| Forecasted market size in 2031 | US$ 9820 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Berry Plastics, Conitex Sonoco, Greif Flexible Products & Services, Plastipak Group, Global-Pak, Bulk Lift International, Halsted, Berenfield Containers Incorporated, BWAY Corporation, Jumbo Bag, Langston, Koch Industries Incorporated, Weidenhammer Packungen, Intertape Polymer Group, J & HM Dickson, LC Packaging |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |