What is Global Industrial Desiccant Dryer Market?

The Global Industrial Desiccant Dryer Market refers to the worldwide industry focused on the production and distribution of desiccant dryers used in various industrial applications. Desiccant dryers are specialized equipment designed to remove moisture from compressed air and gases, ensuring that these systems operate efficiently and without the risk of moisture-related damage. This market is driven by the increasing demand for efficient and reliable drying solutions across industries such as chemical, power, food, and pharmaceuticals. The growth of industrial activities, coupled with the need for high-quality air and gas systems, has led to a rise in the adoption of desiccant dryers. These dryers are essential in maintaining the integrity of industrial processes by preventing moisture-induced corrosion, contamination, and equipment failure. As industries continue to expand and modernize, the demand for advanced desiccant drying technologies is expected to grow, making the Global Industrial Desiccant Dryer Market a vital component of the industrial equipment sector. The market is characterized by a variety of products, including both intermittent and continuous desiccant dryers, each catering to specific industrial needs and operational requirements.

Intermittent Desiccant Dryer, Continuous Desiccant Dryer in the Global Industrial Desiccant Dryer Market:

Intermittent Desiccant Dryers and Continuous Desiccant Dryers are two primary types of equipment within the Global Industrial Desiccant Dryer Market, each serving distinct purposes and operational needs. Intermittent desiccant dryers operate in cycles, alternating between drying and regeneration phases. During the drying phase, moist air passes through a desiccant material, which absorbs the moisture. Once the desiccant becomes saturated, the system switches to the regeneration phase, where the desiccant is dried and prepared for reuse. This type of dryer is particularly useful in applications where the demand for dry air is not constant, allowing for energy savings and efficient operation. Intermittent dryers are often favored in smaller operations or where budget constraints are a consideration, as they can be more cost-effective due to their cyclical operation. On the other hand, Continuous Desiccant Dryers provide a constant supply of dry air, making them ideal for applications where uninterrupted drying is critical. These dryers use a dual-tower system, where one tower is in the drying phase while the other is regenerating. This setup ensures that there is always a supply of dry air available, which is crucial in industries where even a brief interruption in air quality can lead to significant operational issues or product spoilage. Continuous dryers are typically used in larger industrial settings where the demand for dry air is high and consistent, such as in large-scale manufacturing plants or facilities with sensitive equipment that requires constant protection from moisture. The choice between intermittent and continuous desiccant dryers often depends on several factors, including the specific requirements of the industrial process, the volume of air that needs to be dried, and the cost considerations of the operation. Intermittent dryers may be more suitable for smaller operations or those with fluctuating demands, while continuous dryers are better suited for large-scale operations with a constant need for dry air. Additionally, technological advancements in both types of dryers have led to improvements in energy efficiency, reliability, and ease of maintenance, further enhancing their appeal to industrial users. In terms of market dynamics, both intermittent and continuous desiccant dryers are experiencing growth due to the increasing industrialization and the need for high-quality air systems. As industries continue to expand and modernize, the demand for efficient and reliable drying solutions is expected to rise. This growth is further supported by the development of new materials and technologies that enhance the performance and efficiency of desiccant dryers, making them more attractive to a wider range of industries. Overall, the Global Industrial Desiccant Dryer Market is poised for continued growth, driven by the diverse needs of industrial users and the ongoing advancements in drying technology.

Chemical Plant, Power Plant, Food Factory, Pharmaceutical Factory in the Global Industrial Desiccant Dryer Market:

The Global Industrial Desiccant Dryer Market plays a crucial role in various industrial sectors, including chemical plants, power plants, food factories, and pharmaceutical factories, by providing essential moisture control solutions. In chemical plants, desiccant dryers are vital for ensuring the purity and quality of chemical products. Moisture in compressed air systems can lead to contamination and chemical reactions that compromise product integrity. By removing moisture, desiccant dryers help maintain the stability and quality of chemical processes, preventing costly disruptions and ensuring compliance with industry standards. In power plants, desiccant dryers are used to protect sensitive equipment from moisture-induced corrosion and damage. Moisture in compressed air systems can lead to rust and corrosion in turbines, generators, and other critical components, resulting in reduced efficiency and costly repairs. Desiccant dryers help maintain the reliability and efficiency of power generation systems by providing a constant supply of dry air, ensuring that equipment operates smoothly and without interruption. Food factories also rely on desiccant dryers to maintain product quality and safety. Moisture in compressed air systems can lead to contamination and spoilage of food products, posing significant health risks and financial losses. Desiccant dryers help prevent these issues by providing clean, dry air for packaging, processing, and storage operations. This ensures that food products remain fresh and safe for consumption, meeting stringent industry regulations and consumer expectations. In pharmaceutical factories, desiccant dryers are essential for maintaining the purity and efficacy of pharmaceutical products. Moisture in compressed air systems can lead to contamination and degradation of sensitive pharmaceutical compounds, compromising product quality and safety. Desiccant dryers help ensure that pharmaceutical manufacturing processes are conducted in a controlled environment, free from moisture-related risks. This is critical for meeting regulatory requirements and ensuring the safety and effectiveness of pharmaceutical products. Overall, the Global Industrial Desiccant Dryer Market provides essential solutions for moisture control across a wide range of industrial applications. By ensuring the quality and reliability of compressed air systems, desiccant dryers help industries maintain operational efficiency, product quality, and regulatory compliance. As industrial activities continue to grow and evolve, the demand for advanced desiccant drying technologies is expected to increase, further driving the growth of this vital market.

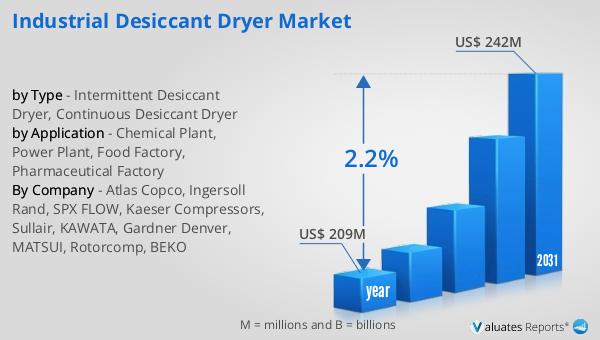

Global Industrial Desiccant Dryer Market Outlook:

The global market for Industrial Desiccant Dryers was valued at approximately $209 million in 2024, with projections indicating that it will reach an adjusted size of around $242 million by 2031. This growth represents a compound annual growth rate (CAGR) of 2.2% over the forecast period. This steady growth can be attributed to the increasing demand for efficient moisture control solutions across various industrial sectors. As industries continue to expand and modernize, the need for reliable and efficient desiccant dryers becomes more pronounced. These dryers play a crucial role in maintaining the quality and reliability of compressed air systems, which are essential for the smooth operation of industrial processes. The market's growth is further supported by advancements in desiccant drying technology, which have led to improvements in energy efficiency, reliability, and ease of maintenance. These advancements make desiccant dryers more attractive to a wider range of industries, driving their adoption and contributing to market growth. Additionally, the increasing focus on sustainability and energy efficiency in industrial operations is expected to further boost the demand for advanced desiccant drying solutions. Overall, the Global Industrial Desiccant Dryer Market is poised for continued growth, driven by the diverse needs of industrial users and the ongoing advancements in drying technology. As industries continue to evolve and face new challenges, the demand for efficient and reliable moisture control solutions is expected to rise, further supporting the market's growth trajectory.

| Report Metric | Details |

| Report Name | Industrial Desiccant Dryer Market |

| Accounted market size in year | US$ 209 million |

| Forecasted market size in 2031 | US$ 242 million |

| CAGR | 2.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Atlas Copco, Ingersoll Rand, SPX FLOW, Kaeser Compressors, Sullair, KAWATA, Gardner Denver, MATSUI, Rotorcomp, BEKO |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |