What is Global Electro Pneumatic Positioners Market?

The Global Electro Pneumatic Positioners Market is a specialized segment within the broader field of industrial automation and control systems. Electro pneumatic positioners are devices used to control the position of valves, dampers, and other mechanical devices by converting electrical signals into pneumatic outputs. These positioners are crucial in industries where precise control of fluid flow is necessary, such as in chemical processing, oil and gas, and manufacturing. The market for these devices is driven by the increasing demand for automation in industrial processes, which enhances efficiency, accuracy, and safety. As industries continue to modernize and adopt more sophisticated control systems, the demand for electro pneumatic positioners is expected to grow. These devices are integral to ensuring that industrial processes run smoothly and efficiently, minimizing downtime and maximizing productivity. The market is characterized by a mix of established players and new entrants, each vying to offer innovative solutions that meet the evolving needs of industrial users. With advancements in technology, electro pneumatic positioners are becoming more reliable, durable, and easier to integrate into existing systems, further fueling their adoption across various sectors.

Single Acting Type, Double Acting Type in the Global Electro Pneumatic Positioners Market:

In the Global Electro Pneumatic Positioners Market, two primary types of positioners are widely used: Single Acting Type and Double Acting Type. Single Acting Type positioners are designed to control the position of a valve using a single pneumatic output. They are typically used in applications where the valve needs to be moved in one direction by the pneumatic signal, with a spring mechanism returning it to its original position. This type of positioner is often favored for its simplicity and reliability, especially in applications where fail-safe operation is critical. For instance, in the event of a power or signal failure, the spring mechanism ensures that the valve returns to a predetermined safe position, minimizing the risk of accidents or damage to equipment. Single Acting Type positioners are commonly used in industries such as oil and gas, where safety and reliability are paramount. On the other hand, Double Acting Type positioners are designed to control the position of a valve using two pneumatic outputs. This allows for more precise control of the valve position, as the positioner can apply pressure to both sides of the actuator, enabling it to move in both directions. Double Acting Type positioners are often used in applications where precise control of the valve position is required, such as in chemical processing or manufacturing. These positioners offer greater flexibility and control compared to Single Acting Type positioners, making them suitable for complex industrial processes that require fine-tuned adjustments. Additionally, Double Acting Type positioners are often used in applications where the valve needs to be held in a specific position for extended periods, as they can maintain the desired position without relying on a spring mechanism. Both Single Acting Type and Double Acting Type positioners have their unique advantages and are chosen based on the specific requirements of the application. Factors such as the type of valve, the nature of the fluid being controlled, and the desired level of control precision all play a role in determining which type of positioner is most suitable. In some cases, the choice between Single Acting and Double Acting Type positioners may also be influenced by cost considerations, as Double Acting Type positioners tend to be more expensive due to their added complexity and functionality. However, the benefits of enhanced control and flexibility often justify the higher cost in applications where precision and reliability are critical. The Global Electro Pneumatic Positioners Market is also influenced by technological advancements that have led to the development of more sophisticated positioners. Modern positioners are equipped with advanced features such as digital communication capabilities, self-diagnostics, and remote monitoring, which enhance their performance and ease of use. These features allow for seamless integration with existing control systems, enabling operators to monitor and adjust the positioners remotely, reducing the need for manual intervention and improving overall efficiency. As industries continue to embrace digital transformation, the demand for advanced electro pneumatic positioners is expected to increase, driving further innovation and growth in the market. In conclusion, the Global Electro Pneumatic Positioners Market is characterized by a diverse range of products designed to meet the specific needs of various industrial applications. Whether it's the simplicity and reliability of Single Acting Type positioners or the precision and flexibility of Double Acting Type positioners, these devices play a crucial role in ensuring the smooth and efficient operation of industrial processes. As technology continues to evolve, the market is poised for continued growth, driven by the increasing demand for automation and the need for more sophisticated control solutions.

Chemical Industry, Oil Industry, Other in the Global Electro Pneumatic Positioners Market:

The Global Electro Pneumatic Positioners Market finds extensive usage across various industries, including the Chemical Industry, Oil Industry, and others. In the Chemical Industry, electro pneumatic positioners are essential for controlling the flow of chemicals through pipelines and reactors. The precise control offered by these positioners ensures that chemical reactions occur under optimal conditions, enhancing product quality and yield. In processes such as distillation, mixing, and polymerization, maintaining accurate control over fluid flow is crucial to achieving the desired chemical composition and properties. Electro pneumatic positioners enable operators to adjust valve positions with high precision, ensuring that the right amount of reactants are introduced into the process at the right time. This level of control is vital for maintaining safety, as it helps prevent overpressure situations and potential chemical spills. In the Oil Industry, electro pneumatic positioners are used to regulate the flow of oil and gas through pipelines and processing facilities. The harsh and demanding conditions of oil extraction and processing require equipment that is robust and reliable. Electro pneumatic positioners are designed to withstand extreme temperatures, pressures, and corrosive environments, making them ideal for use in the oil industry. These positioners play a critical role in ensuring the safe and efficient operation of oil rigs, refineries, and distribution networks. By providing precise control over valve positions, they help optimize the flow of oil and gas, reducing the risk of leaks and ensuring that production targets are met. Additionally, the ability to remotely monitor and adjust positioners enhances operational efficiency, allowing operators to respond quickly to changing conditions and minimize downtime. Beyond the Chemical and Oil Industries, electro pneumatic positioners are used in a variety of other sectors, including water treatment, power generation, and food and beverage processing. In water treatment facilities, these positioners are used to control the flow of water and chemicals, ensuring that water is treated to the required standards before being released into the environment or distributed for consumption. In power generation, electro pneumatic positioners are used to regulate the flow of steam and other fluids, optimizing the efficiency of turbines and boilers. In the food and beverage industry, these positioners help maintain the precise control needed for processes such as fermentation, pasteurization, and bottling, ensuring product quality and consistency. The versatility and reliability of electro pneumatic positioners make them indispensable in a wide range of industrial applications. As industries continue to seek ways to improve efficiency, reduce costs, and enhance safety, the demand for these devices is expected to grow. The ability to integrate with modern control systems and provide real-time data on process conditions further enhances their appeal, enabling operators to make informed decisions and optimize their operations. In summary, the Global Electro Pneumatic Positioners Market plays a vital role in supporting the efficient and safe operation of industrial processes across multiple sectors, contributing to improved productivity and sustainability.

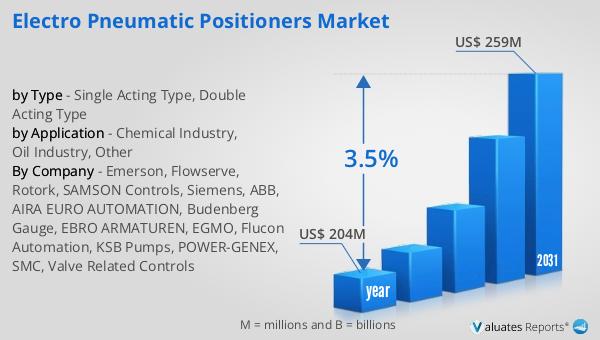

Global Electro Pneumatic Positioners Market Outlook:

The outlook for the Global Electro Pneumatic Positioners Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 204 million, and it is anticipated to expand to a revised size of US$ 259 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.5% over the forecast period. This upward trend reflects the increasing demand for automation and precise control in various industrial sectors. Notably, prominent companies such as Emerson, Rotork, and Siemens hold a significant share of the market, collectively accounting for over 37%. These industry leaders are known for their innovative solutions and commitment to quality, which have helped them maintain a strong presence in the market. Their continued investment in research and development is likely to drive further advancements in electro pneumatic positioner technology, enhancing performance and expanding application possibilities. As industries continue to modernize and prioritize efficiency, the demand for reliable and advanced positioners is expected to rise, contributing to the overall growth of the market. The competitive landscape is characterized by a mix of established players and emerging companies, each striving to capture a share of this dynamic and evolving market.

| Report Metric | Details |

| Report Name | Electro Pneumatic Positioners Market |

| Accounted market size in year | US$ 204 million |

| Forecasted market size in 2031 | US$ 259 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Emerson, Flowserve, Rotork, SAMSON Controls, Siemens, ABB, AIRA EURO AUTOMATION, Budenberg Gauge, EBRO ARMATUREN, EGMO, Flucon Automation, KSB Pumps, POWER-GENEX, SMC, Valve Related Controls |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |