What is Global Gas Cutting Machinery Market?

The Global Gas Cutting Machinery Market is a dynamic and essential segment of the industrial machinery sector, focusing on equipment designed to cut through metal using gas-fueled torches. This market encompasses a variety of machinery types, each tailored to specific industrial needs, ranging from small-scale manual devices to large, automated systems. Gas cutting machinery is crucial in industries where precision and efficiency in metal cutting are paramount, such as construction, automotive, and shipbuilding. The market is driven by the demand for high-quality metal cutting solutions that offer speed, accuracy, and cost-effectiveness. Technological advancements have led to the development of more sophisticated machinery, capable of handling complex cutting tasks with minimal human intervention. As industries continue to expand and modernize, the need for reliable and efficient gas cutting machinery is expected to grow, making this market a vital component of the global industrial landscape. The market's growth is also influenced by factors such as the increasing adoption of automation in manufacturing processes and the rising demand for energy-efficient and environmentally friendly cutting solutions. Overall, the Global Gas Cutting Machinery Market plays a critical role in supporting industrial operations worldwide, providing the tools necessary for precise and efficient metal cutting.

Semi-automatic Gas Cutting Machinery, Manual Gas Cutting Machinery, CNC Gas Cutting Machinery in the Global Gas Cutting Machinery Market:

In the Global Gas Cutting Machinery Market, there are several types of machinery that cater to different industrial needs, including Semi-automatic Gas Cutting Machinery, Manual Gas Cutting Machinery, and CNC Gas Cutting Machinery. Semi-automatic gas cutting machinery is designed to offer a balance between manual operation and automation. These machines are equipped with features that allow for some level of automation, such as automatic torch height adjustment and guided cutting paths, while still requiring human intervention for setup and monitoring. This type of machinery is ideal for small to medium-sized enterprises that need efficient cutting solutions without the high costs associated with fully automated systems. Manual gas cutting machinery, on the other hand, relies entirely on human operation. These machines are typically more affordable and are used in situations where precision is not as critical, or where the volume of work does not justify the investment in more advanced equipment. Manual gas cutting machines are portable and versatile, making them suitable for on-site work and smaller projects. CNC gas cutting machinery represents the pinnacle of automation in the gas cutting market. These machines are controlled by computer numerical control (CNC) systems, which allow for precise and complex cutting operations with minimal human intervention. CNC gas cutting machines are used in industries where high precision and repeatability are essential, such as aerospace and automotive manufacturing. They are capable of cutting intricate shapes and patterns with high accuracy, making them indispensable for large-scale production environments. The choice between these types of machinery depends on various factors, including the specific requirements of the task, budget constraints, and the desired level of automation. Each type of gas cutting machinery offers unique advantages and is suited to different applications, ensuring that businesses can find the right solution for their metal cutting needs.

Automobile Industry, Shipping Industry, Equipment Manufacturing Industry, Other in the Global Gas Cutting Machinery Market:

The Global Gas Cutting Machinery Market finds extensive usage across various industries, including the Automobile Industry, Shipping Industry, Equipment Manufacturing Industry, and others. In the automobile industry, gas cutting machinery is used for cutting and shaping metal components that form the structural framework of vehicles. The precision and efficiency offered by gas cutting machines are crucial for producing high-quality automotive parts that meet stringent safety and performance standards. These machines enable manufacturers to cut complex shapes and designs with ease, contributing to the overall efficiency of the production process. In the shipping industry, gas cutting machinery plays a vital role in the construction and maintenance of ships. The ability to cut through thick metal plates with precision is essential for building robust and durable vessels. Gas cutting machines are used to fabricate various ship components, including hulls, decks, and bulkheads, ensuring that they meet the necessary specifications for strength and durability. The equipment manufacturing industry also relies heavily on gas cutting machinery for the production of a wide range of industrial equipment. From heavy machinery to precision tools, gas cutting machines are used to cut and shape metal parts that are integral to the functionality of these products. The versatility and accuracy of gas cutting machinery make it an indispensable tool in this industry, allowing manufacturers to produce high-quality equipment that meets the demands of their customers. Beyond these industries, gas cutting machinery is used in various other sectors, including construction, aerospace, and energy. In construction, gas cutting machines are used for cutting steel beams and other structural components, while in aerospace, they are used for fabricating aircraft parts. In the energy sector, gas cutting machinery is used for cutting and shaping metal components used in power generation and distribution systems. Overall, the Global Gas Cutting Machinery Market serves a wide range of industries, providing the tools necessary for efficient and precise metal cutting operations.

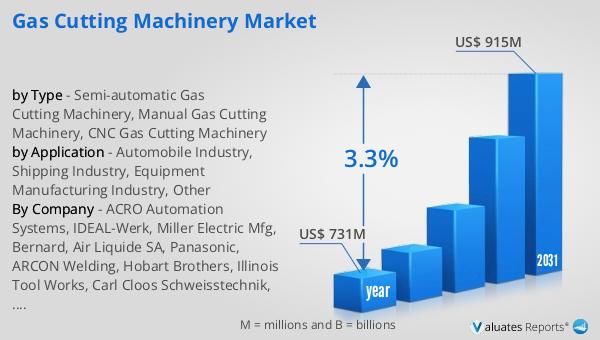

Global Gas Cutting Machinery Market Outlook:

The global market for Gas Cutting Machinery was valued at $731 million in 2024 and is anticipated to grow to a revised size of $915 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.3% over the forecast period. This growth trajectory underscores the increasing demand for gas cutting machinery across various industries, driven by the need for efficient and precise metal cutting solutions. The market's expansion is fueled by technological advancements that have led to the development of more sophisticated machinery, capable of handling complex cutting tasks with minimal human intervention. As industries continue to modernize and adopt automation in their manufacturing processes, the demand for gas cutting machinery is expected to rise. Additionally, the growing emphasis on energy efficiency and environmental sustainability is driving the adoption of advanced gas cutting solutions that offer reduced energy consumption and lower emissions. The market's growth is also supported by the increasing demand for high-quality metal cutting solutions in emerging economies, where industrialization and infrastructure development are on the rise. Overall, the Global Gas Cutting Machinery Market is poised for steady growth, providing essential tools for industries worldwide to enhance their production capabilities and meet the evolving demands of their customers.

| Report Metric | Details |

| Report Name | Gas Cutting Machinery Market |

| Accounted market size in year | US$ 731 million |

| Forecasted market size in 2031 | US$ 915 million |

| CAGR | 3.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ACRO Automation Systems, IDEAL-Werk, Miller Electric Mfg, Bernard, Air Liquide SA, Panasonic, ARCON Welding, Hobart Brothers, Illinois Tool Works, Carl Cloos Schweisstechnik, Daihen, Denyo, ESAB, Fronius International, GSI Group, IGM Robotersysteme AG, KUKA Aktiengesellschaft, Kemppi |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |