What is Global Pharmaceutical Packaging Glass Market?

The Global Pharmaceutical Packaging Glass Market is a crucial segment within the broader pharmaceutical industry, focusing on the production and supply of glass containers specifically designed for pharmaceutical products. These glass containers are essential for ensuring the safety, efficacy, and stability of medications, as they provide a non-reactive and impermeable barrier that protects the contents from contamination and degradation. The market encompasses a wide range of products, including vials, ampoules, bottles, and syringes, each tailored to meet the specific needs of different pharmaceutical applications. The demand for pharmaceutical packaging glass is driven by the increasing production of pharmaceuticals, the need for safe and reliable packaging solutions, and the growing emphasis on sustainability and recyclability. Glass is favored in the pharmaceutical industry due to its inert nature, which prevents interactions with the drug formulations, thereby maintaining the integrity of the medication. Additionally, the market is influenced by regulatory standards and guidelines that mandate the use of high-quality packaging materials to ensure patient safety. As the pharmaceutical industry continues to expand globally, the demand for pharmaceutical packaging glass is expected to grow, driven by advancements in drug development and the increasing prevalence of chronic diseases.

Colored Glass, Colorless Glass in the Global Pharmaceutical Packaging Glass Market:

Colored glass and colorless glass are two primary types of glass used in the Global Pharmaceutical Packaging Glass Market, each serving distinct purposes and offering unique benefits. Colored glass, often amber or green, is primarily used to protect light-sensitive medications from degradation caused by exposure to ultraviolet (UV) and visible light. This type of glass acts as a barrier, filtering out harmful light rays that can compromise the stability and efficacy of certain pharmaceuticals, such as antibiotics, vitamins, and biologics. The use of colored glass is crucial in maintaining the potency of these medications throughout their shelf life, ensuring that patients receive the intended therapeutic effects. On the other hand, colorless glass, also known as flint glass, is widely used for its transparency, which allows for easy inspection of the contents. This is particularly important for quality control purposes, as it enables healthcare professionals and patients to visually assess the clarity and purity of the medication. Colorless glass is often used for products where light sensitivity is not a concern, such as saline solutions, certain injectables, and oral liquid medications. Both colored and colorless glass are manufactured to meet stringent quality standards, ensuring that they are free from defects and contaminants that could compromise the safety and efficacy of the pharmaceutical products they contain. The choice between colored and colorless glass depends on several factors, including the nature of the medication, its sensitivity to light, and the specific requirements of the pharmaceutical manufacturer. In addition to their functional benefits, both types of glass are valued for their environmental sustainability, as they are fully recyclable and can be reused in the production of new glass containers. This aligns with the growing emphasis on eco-friendly packaging solutions within the pharmaceutical industry, as companies seek to reduce their environmental footprint and promote sustainable practices. The production of pharmaceutical packaging glass involves advanced manufacturing processes that ensure the highest levels of precision and quality. This includes the use of specialized equipment and techniques to produce glass containers with uniform thickness, smooth surfaces, and precise dimensions. These attributes are essential for ensuring the compatibility of the glass containers with automated filling and sealing equipment used in pharmaceutical manufacturing. Furthermore, the glass must be chemically resistant to prevent interactions with the drug formulations, which could lead to contamination or degradation. The Global Pharmaceutical Packaging Glass Market is characterized by continuous innovation and development, as manufacturers strive to enhance the performance and functionality of their products. This includes the introduction of new glass formulations with improved barrier properties, as well as the development of advanced coatings and treatments that enhance the durability and chemical resistance of the glass. As the pharmaceutical industry continues to evolve, the demand for high-quality pharmaceutical packaging glass is expected to grow, driven by the increasing complexity of drug formulations and the need for specialized packaging solutions.

Vaccine Packaging, Infusion Bottle, Other in the Global Pharmaceutical Packaging Glass Market:

The Global Pharmaceutical Packaging Glass Market plays a vital role in various applications, including vaccine packaging, infusion bottles, and other pharmaceutical products. Vaccine packaging is a critical application area, as vaccines require stringent storage conditions to maintain their efficacy and safety. Glass vials and ampoules are commonly used for vaccine packaging due to their excellent barrier properties, which protect the sensitive biological components from contamination and degradation. The inert nature of glass ensures that there are no interactions between the container and the vaccine, preserving the stability and potency of the vaccine throughout its shelf life. Additionally, glass packaging provides a secure seal that prevents the entry of air and moisture, which could compromise the vaccine's effectiveness. Infusion bottles are another important application of pharmaceutical packaging glass, used for the storage and administration of intravenous (IV) fluids and medications. Glass infusion bottles are preferred for their transparency, allowing healthcare professionals to visually inspect the contents for clarity and purity before administration. This is crucial for ensuring patient safety, as any particulate matter or discoloration could indicate contamination or degradation of the solution. The use of glass infusion bottles also ensures compatibility with a wide range of IV medications, as the inert nature of glass prevents chemical interactions that could alter the composition of the drug. In addition to vaccine packaging and infusion bottles, pharmaceutical packaging glass is used in a variety of other applications, including the packaging of oral liquid medications, ophthalmic solutions, and injectable drugs. The versatility of glass makes it an ideal choice for these applications, as it can be easily molded into different shapes and sizes to accommodate the specific requirements of each product. The use of glass in these applications ensures that the medications remain safe, effective, and free from contamination throughout their shelf life. Furthermore, the recyclability of glass aligns with the growing emphasis on sustainable packaging solutions within the pharmaceutical industry, as companies seek to reduce their environmental impact and promote eco-friendly practices. The Global Pharmaceutical Packaging Glass Market is characterized by continuous innovation and development, as manufacturers strive to enhance the performance and functionality of their products. This includes the introduction of new glass formulations with improved barrier properties, as well as the development of advanced coatings and treatments that enhance the durability and chemical resistance of the glass. As the pharmaceutical industry continues to evolve, the demand for high-quality pharmaceutical packaging glass is expected to grow, driven by the increasing complexity of drug formulations and the need for specialized packaging solutions.

Global Pharmaceutical Packaging Glass Market Outlook:

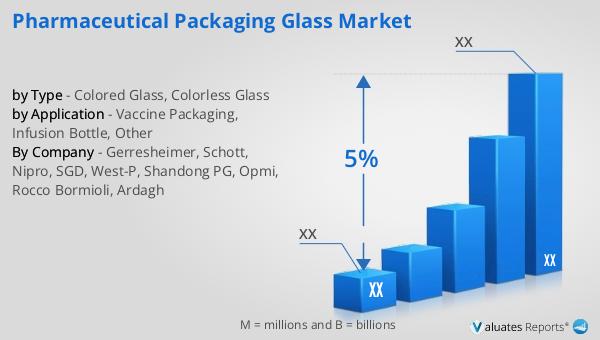

In 2022, the global pharmaceutical market reached a valuation of 1,475 billion USD, marking a significant milestone in the industry's growth trajectory. This expansion is projected to continue at a compound annual growth rate (CAGR) of 5% over the next six years, reflecting the increasing demand for pharmaceutical products worldwide. This growth is driven by several factors, including advancements in drug development, the rising prevalence of chronic diseases, and the growing emphasis on personalized medicine. In comparison, the chemical drug market has also experienced notable growth, with its value increasing from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This upward trend highlights the sustained demand for chemical drugs, which continue to play a crucial role in the treatment and management of various medical conditions. The growth of the chemical drug market is supported by ongoing research and development efforts, as well as the introduction of new and innovative drug formulations. As the pharmaceutical industry continues to evolve, the demand for high-quality packaging solutions, such as pharmaceutical packaging glass, is expected to grow in tandem, driven by the need to ensure the safety, efficacy, and stability of medications. The Global Pharmaceutical Packaging Glass Market is poised to benefit from these trends, as manufacturers strive to meet the increasing demand for safe and reliable packaging solutions that align with regulatory standards and guidelines.

| Report Metric | Details |

| Report Name | Pharmaceutical Packaging Glass Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Gerresheimer, Schott, Nipro, SGD, West-P, Shandong PG, Opmi, Rocco Bormioli, Ardagh |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |