What is Global Pad Printing Equipment Market?

The Global Pad Printing Equipment Market is a specialized segment within the broader printing industry, focusing on the production and distribution of machines designed for pad printing. Pad printing is a unique printing process that allows for the transfer of 2D images onto 3D objects, making it highly versatile and suitable for a wide range of applications. This market encompasses various types of equipment, including single-color and multi-color pad printers, which cater to different printing needs and complexities. The demand for pad printing equipment is driven by its ability to print on irregular surfaces and a variety of materials, such as plastics, metals, glass, and ceramics. Industries such as automotive, electronics, medical, and consumer goods heavily rely on pad printing for branding, labeling, and decorative purposes. The market is characterized by technological advancements aimed at improving printing precision, speed, and efficiency, as well as reducing environmental impact. As industries continue to innovate and expand, the Global Pad Printing Equipment Market is expected to evolve, offering new opportunities for manufacturers and end-users alike. The market's growth is also influenced by the increasing demand for customized and high-quality printed products, which pad printing equipment is well-suited to deliver.

Single-Color Pad Printers, Multi-Color Pad Printers in the Global Pad Printing Equipment Market:

Single-color pad printers are a fundamental component of the Global Pad Printing Equipment Market, offering a straightforward solution for printing tasks that require a single ink color. These machines are typically used for simpler designs or when the printing process needs to be quick and efficient. Single-color pad printers are favored for their ease of use, cost-effectiveness, and ability to produce high-quality prints on a variety of substrates. They are commonly employed in industries where branding and labeling are essential, such as in the production of promotional items, toys, and small electronic components. The simplicity of single-color pad printers makes them an attractive option for businesses looking to enter the pad printing market without a significant initial investment. On the other hand, multi-color pad printers are designed to handle more complex printing tasks that require multiple ink colors. These machines are equipped with advanced features that allow for precise color registration and alignment, ensuring that each color is applied accurately and consistently. Multi-color pad printers are essential for industries that demand intricate designs and high-quality finishes, such as the automotive and electronics sectors. The ability to print multiple colors in a single pass reduces production time and increases efficiency, making these machines a valuable asset for high-volume production environments. The versatility of multi-color pad printers also extends to their ability to print on a wide range of materials, including plastics, metals, and ceramics, further enhancing their appeal to various industries. As the demand for customized and visually appealing products continues to rise, the role of multi-color pad printers in the Global Pad Printing Equipment Market is expected to grow. Both single-color and multi-color pad printers play a crucial role in meeting the diverse needs of industries that rely on pad printing for their production processes. While single-color printers offer a cost-effective solution for simpler tasks, multi-color printers provide the flexibility and precision required for more complex designs. The choice between single-color and multi-color pad printers ultimately depends on the specific requirements of the application, including the desired level of detail, production volume, and budget constraints. As technology continues to advance, both types of pad printers are likely to see improvements in terms of speed, accuracy, and environmental sustainability, further solidifying their position in the Global Pad Printing Equipment Market.

Medical, Automotive, Electronics, Consumer Goods, Others in the Global Pad Printing Equipment Market:

The Global Pad Printing Equipment Market finds extensive usage across various industries, each leveraging the unique capabilities of pad printing to meet their specific needs. In the medical industry, pad printing is crucial for labeling medical devices, surgical instruments, and pharmaceutical packaging. The ability to print on curved and irregular surfaces ensures that critical information, such as dosage instructions and safety warnings, is clearly visible and durable. Pad printing's precision and reliability make it an ideal choice for the stringent requirements of the medical sector, where accuracy and compliance with regulatory standards are paramount. In the automotive industry, pad printing is used for decorating and labeling interior and exterior components, such as dashboard controls, buttons, and emblems. The durability of pad-printed designs ensures that they can withstand the harsh conditions of automotive environments, including exposure to sunlight, temperature fluctuations, and abrasion. The versatility of pad printing allows for the use of a wide range of inks and substrates, enabling manufacturers to achieve the desired aesthetic and functional properties for their products. The electronics industry also benefits significantly from pad printing, particularly in the production of small and intricate components, such as circuit boards, connectors, and switches. Pad printing's ability to deliver precise and consistent results is essential for maintaining the performance and reliability of electronic devices. The process is also used for branding and labeling consumer electronics, such as smartphones, laptops, and home appliances, where high-quality finishes and detailed designs are important for brand differentiation. In the consumer goods sector, pad printing is widely used for decorating and personalizing products, such as toys, sports equipment, and household items. The ability to print on a variety of materials, including plastics, metals, and glass, makes pad printing a versatile solution for manufacturers looking to enhance the visual appeal and functionality of their products. The demand for customized and unique consumer goods continues to drive innovation in pad printing technology, enabling manufacturers to offer a wider range of design options and finishes. Beyond these industries, pad printing is also used in other sectors, such as aerospace, textiles, and promotional products, where its ability to print on complex shapes and surfaces is highly valued. The Global Pad Printing Equipment Market's adaptability and efficiency make it a vital tool for businesses seeking to enhance their product offerings and meet the evolving demands of their customers. As industries continue to innovate and expand, the role of pad printing in supporting their growth and success is expected to remain significant.

Global Pad Printing Equipment Market Outlook:

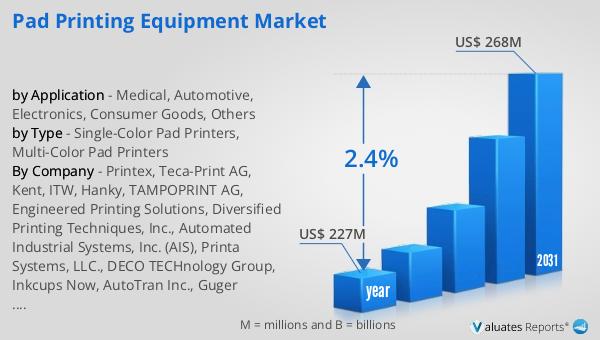

In 2024, the Global Pad Printing Equipment Market was valued at approximately $227 million. By 2031, it is anticipated to grow to a revised size of around $268 million, reflecting a compound annual growth rate (CAGR) of 2.4% over the forecast period. This growth trajectory highlights the steady demand for pad printing equipment across various industries, driven by the need for high-quality, precise, and versatile printing solutions. The market is characterized by a competitive landscape, with the top five pad printing supplies players accounting for about 29% of the total global market. This concentration indicates a significant level of competition among leading manufacturers, who are continuously striving to innovate and enhance their product offerings to capture a larger share of the market. The growth of the Global Pad Printing Equipment Market is supported by technological advancements that improve the efficiency, speed, and environmental sustainability of pad printing processes. As industries such as automotive, electronics, medical, and consumer goods continue to expand and evolve, the demand for reliable and high-performance pad printing equipment is expected to remain strong. The market's steady growth also reflects the increasing importance of customization and branding in today's competitive business environment, where companies seek to differentiate their products and enhance their appeal to consumers. As a result, the Global Pad Printing Equipment Market is poised for continued development, offering new opportunities for manufacturers and end-users alike.

| Report Metric | Details |

| Report Name | Pad Printing Equipment Market |

| Accounted market size in year | US$ 227 million |

| Forecasted market size in 2031 | US$ 268 million |

| CAGR | 2.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Printex, Teca-Print AG, Kent, ITW, Hanky, TAMPOPRINT AG, Engineered Printing Solutions, Diversified Printing Techniques, Inc., Automated Industrial Systems, Inc. (AIS), Printa Systems, LLC., DECO TECHnology Group, Inkcups Now, AutoTran Inc., Guger Industries Co, Ltd., Tampo Ltd, Luen Cheong Printing, Comdec Incorporated, Finecause CO.,LTD., Mascoprint, Howell Print Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |