What is Global Medium Voltage Motor Control Center Market?

The Global Medium Voltage Motor Control Center (MCC) Market is a crucial segment within the broader electrical equipment industry, focusing on the management and control of electric motors that operate at medium voltage levels, typically ranging from 1 kV to 15 kV. These MCCs are essential for industries that rely heavily on motor-driven processes, such as manufacturing, oil and gas, mining, and utilities. They provide a centralized system to control and protect motors, ensuring efficient operation and reducing downtime. The market is driven by the increasing demand for energy-efficient solutions and the need to upgrade aging infrastructure in developed regions. Additionally, the rapid industrialization and urbanization in emerging economies are contributing to the growth of this market. The integration of advanced technologies, such as IoT and automation, into MCCs is also enhancing their functionality, making them more intelligent and capable of predictive maintenance. This evolution is helping industries to optimize their operations, reduce energy consumption, and improve safety standards. As industries continue to seek ways to enhance operational efficiency and sustainability, the demand for medium voltage MCCs is expected to grow steadily.

Intelligent medium voltage MCC, Conventional medium voltage MCC in the Global Medium Voltage Motor Control Center Market:

Intelligent Medium Voltage Motor Control Centers (MCCs) represent a significant advancement over conventional MCCs, offering enhanced capabilities through the integration of digital technologies. These intelligent systems are equipped with advanced communication protocols, sensors, and software that enable real-time monitoring and control of motor operations. This allows for predictive maintenance, reducing the likelihood of unexpected failures and minimizing downtime. Intelligent MCCs can communicate with other systems within a facility, providing valuable data that can be used to optimize energy consumption and improve overall operational efficiency. They are particularly beneficial in industries where uptime is critical, such as oil and gas, mining, and manufacturing. On the other hand, conventional medium voltage MCCs, while still widely used, lack the advanced features of their intelligent counterparts. They primarily focus on basic motor control and protection functions, such as starting, stopping, and overload protection. These systems are typically more cost-effective and simpler to operate, making them suitable for applications where advanced monitoring and control are not required. However, as industries increasingly prioritize efficiency and reliability, the shift towards intelligent MCCs is becoming more pronounced. The integration of IoT and automation technologies into MCCs is transforming the way industries manage their motor-driven processes. Intelligent MCCs offer several advantages over conventional systems, including improved diagnostics, remote monitoring, and enhanced safety features. They can detect anomalies in motor performance and alert operators to potential issues before they lead to costly downtime. This proactive approach to maintenance not only extends the lifespan of motors but also reduces operational costs. Furthermore, intelligent MCCs can be integrated with energy management systems, allowing industries to optimize their energy usage and reduce their carbon footprint. This is particularly important in today's environmentally conscious world, where sustainability is a key consideration for many businesses. Despite the benefits of intelligent MCCs, conventional systems still have a place in the market. They are often preferred in applications where simplicity and cost-effectiveness are more important than advanced features. For example, in smaller facilities or less critical applications, conventional MCCs can provide reliable motor control without the need for complex monitoring and control capabilities. However, as technology continues to evolve and the cost of intelligent systems decreases, it is likely that the adoption of intelligent MCCs will continue to grow. In conclusion, the Global Medium Voltage Motor Control Center Market is witnessing a shift towards more advanced, intelligent systems that offer enhanced capabilities and improved efficiency. While conventional MCCs remain relevant in certain applications, the benefits of intelligent systems are driving their adoption across a wide range of industries. As businesses strive to improve operational efficiency and reduce costs, the demand for intelligent MCCs is expected to increase, shaping the future of the market.

Oil, Chemical, Mining, Other in the Global Medium Voltage Motor Control Center Market:

The Global Medium Voltage Motor Control Center Market plays a vital role in various industries, including oil, chemical, mining, and others, by providing essential motor control and protection solutions. In the oil industry, MCCs are crucial for managing the numerous motors used in drilling, pumping, and refining processes. These systems ensure that motors operate efficiently and safely, reducing the risk of costly downtime and enhancing overall productivity. The harsh environments often encountered in oil extraction and processing require robust and reliable MCCs that can withstand extreme conditions. Intelligent MCCs, with their advanced monitoring and diagnostic capabilities, are particularly beneficial in this sector, allowing operators to detect and address potential issues before they escalate. In the chemical industry, MCCs are used to control motors that drive various processes, such as mixing, heating, and cooling. The precise control offered by these systems is essential for maintaining product quality and consistency. Intelligent MCCs provide real-time data on motor performance, enabling operators to optimize processes and reduce energy consumption. This is especially important in the chemical industry, where energy costs can be a significant portion of operational expenses. The ability to monitor and control motors remotely also enhances safety by reducing the need for personnel to be present in hazardous areas. The mining industry relies heavily on MCCs to manage the motors used in extraction, crushing, and material handling processes. The demanding nature of mining operations requires MCCs that can deliver reliable performance under challenging conditions. Intelligent MCCs offer several advantages in this sector, including improved diagnostics and predictive maintenance capabilities. By identifying potential issues before they lead to equipment failure, these systems help to minimize downtime and maximize productivity. Additionally, the integration of MCCs with other mining equipment allows for more efficient coordination of operations, further enhancing productivity. Beyond these industries, MCCs are used in a variety of other applications, such as water treatment, power generation, and manufacturing. In each of these areas, MCCs provide essential motor control and protection functions, ensuring that operations run smoothly and efficiently. The adoption of intelligent MCCs is growing across all sectors, driven by the need for improved efficiency, reliability, and safety. As industries continue to evolve and embrace digital transformation, the role of MCCs in optimizing motor-driven processes is becoming increasingly important. In conclusion, the Global Medium Voltage Motor Control Center Market is integral to the efficient operation of various industries. By providing essential motor control and protection solutions, MCCs help to enhance productivity, reduce costs, and improve safety. The shift towards intelligent MCCs is transforming the way industries manage their motor-driven processes, offering significant benefits in terms of efficiency, reliability, and sustainability. As industries continue to seek ways to optimize their operations, the demand for advanced MCC solutions is expected to grow, driving the evolution of the market.

Global Medium Voltage Motor Control Center Market Outlook:

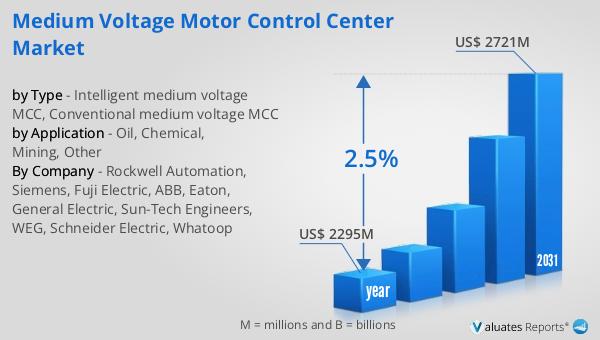

The global market for Medium Voltage Motor Control Centers was valued at approximately $2,295 million in 2024. It is anticipated to expand to a revised size of around $2,721 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.5% over the forecast period. This growth trajectory underscores the increasing demand for efficient and reliable motor control solutions across various industries. The market's expansion is driven by several factors, including the need to upgrade aging infrastructure, the push for energy-efficient solutions, and the rapid industrialization in emerging economies. As industries continue to evolve and embrace digital transformation, the role of medium voltage MCCs in optimizing motor-driven processes is becoming increasingly important. The integration of advanced technologies, such as IoT and automation, into MCCs is enhancing their functionality, making them more intelligent and capable of predictive maintenance. This evolution is helping industries to optimize their operations, reduce energy consumption, and improve safety standards. As businesses strive to improve operational efficiency and reduce costs, the demand for medium voltage MCCs is expected to grow steadily, shaping the future of the market.

| Report Metric | Details |

| Report Name | Medium Voltage Motor Control Center Market |

| Accounted market size in year | US$ 2295 million |

| Forecasted market size in 2031 | US$ 2721 million |

| CAGR | 2.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Rockwell Automation, Siemens, Fuji Electric, ABB, Eaton, General Electric, Sun-Tech Engineers, WEG, Schneider Electric, Whatoop |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |