What is Global Pharmaceutical Membrane Filtration Market?

The Global Pharmaceutical Membrane Filtration Market is a specialized segment within the broader pharmaceutical industry, focusing on the use of membrane filtration technologies to ensure the purity and safety of pharmaceutical products. Membrane filtration is a critical process used to separate, concentrate, and purify components in pharmaceutical manufacturing. This market encompasses various types of membrane filters, each designed to meet specific filtration needs, such as removing particulates, bacteria, and other contaminants from liquids and gases. The demand for membrane filtration in the pharmaceutical sector is driven by the need for high-quality products, stringent regulatory requirements, and the growing complexity of pharmaceutical formulations. As pharmaceutical companies strive to enhance product quality and comply with regulatory standards, the adoption of advanced membrane filtration technologies is becoming increasingly important. This market is characterized by continuous innovation, with companies investing in research and development to create more efficient and effective filtration solutions. The global pharmaceutical membrane filtration market is poised for growth as the pharmaceutical industry expands and evolves, driven by factors such as increasing drug production, the rise of biologics, and the need for sustainable manufacturing practices.

MCE Membrane Filters, Coated Cellulose Acetate Membrane Filters, Nylon Membrane Filters, PVDF Membrane Filters, Others in the Global Pharmaceutical Membrane Filtration Market:

MCE (Mixed Cellulose Ester) Membrane Filters are widely used in the pharmaceutical industry due to their high flow rates and excellent retention capabilities. These filters are composed of cellulose acetate and cellulose nitrate, providing a uniform pore structure that ensures efficient filtration. MCE filters are particularly effective in microbial analysis and sterility testing, making them indispensable in quality control processes. Their hydrophilic nature allows for easy wetting, which is crucial for consistent filtration performance. Coated Cellulose Acetate Membrane Filters, on the other hand, are known for their low protein binding properties, making them ideal for applications where sample integrity is paramount. These filters are often used in the filtration of biological fluids and cell culture media, where maintaining the biological activity of proteins is essential. Nylon Membrane Filters are another popular choice in the pharmaceutical sector, valued for their chemical compatibility and mechanical strength. These filters are suitable for a wide range of applications, including the filtration of solvents, buffers, and other aqueous solutions. Nylon filters are also resistant to a variety of chemicals, making them versatile for different pharmaceutical processes. PVDF (Polyvinylidene Fluoride) Membrane Filters are renowned for their high thermal stability and chemical resistance, making them suitable for demanding filtration applications. These filters are often used in the filtration of aggressive solvents and high-temperature solutions, where other filter materials might fail. PVDF filters are also hydrophobic, which makes them ideal for air and gas filtration applications. Other types of membrane filters used in the pharmaceutical industry include PTFE (Polytetrafluoroethylene) and PES (Polyethersulfone) filters. PTFE filters are highly resistant to solvents and acids, making them suitable for harsh chemical environments. They are often used in the filtration of corrosive liquids and gases. PES filters, on the other hand, are known for their high flow rates and low protein binding, making them ideal for sterile filtration of biological solutions. Each type of membrane filter offers unique advantages, and the choice of filter depends on the specific requirements of the pharmaceutical application. As the pharmaceutical industry continues to evolve, the demand for specialized membrane filters is expected to grow, driven by the need for efficient and reliable filtration solutions.

Final Product Processing, Raw Material Filtration, Cell Separation, Water Purification, Air Purification in the Global Pharmaceutical Membrane Filtration Market:

The Global Pharmaceutical Membrane Filtration Market plays a crucial role in various stages of pharmaceutical manufacturing, ensuring the purity and safety of products. In Final Product Processing, membrane filtration is used to remove impurities and contaminants from the finished product, ensuring that it meets the required quality standards. This process is essential for maintaining the efficacy and safety of pharmaceutical products, as even trace amounts of contaminants can affect their performance. In Raw Material Filtration, membrane filters are used to purify the raw materials used in drug production. This step is critical for ensuring that the starting materials are free from impurities that could compromise the quality of the final product. Cell Separation is another important application of membrane filtration in the pharmaceutical industry. This process involves the separation of cells from culture media, which is essential for the production of biologics and other cell-based therapies. Membrane filters are used to selectively retain or remove cells, ensuring that the desired cell population is obtained. Water Purification is a vital application of membrane filtration, as water is a key component in pharmaceutical manufacturing. Membrane filters are used to remove particulates, bacteria, and other contaminants from water, ensuring that it meets the stringent quality standards required for pharmaceutical use. Air Purification is also an important aspect of pharmaceutical manufacturing, as airborne contaminants can compromise product quality. Membrane filters are used in air filtration systems to remove particulates and microorganisms from the air, ensuring a clean and controlled manufacturing environment. Each of these applications highlights the importance of membrane filtration in ensuring the quality and safety of pharmaceutical products. As the pharmaceutical industry continues to grow and evolve, the demand for advanced membrane filtration technologies is expected to increase, driven by the need for efficient and reliable filtration solutions.

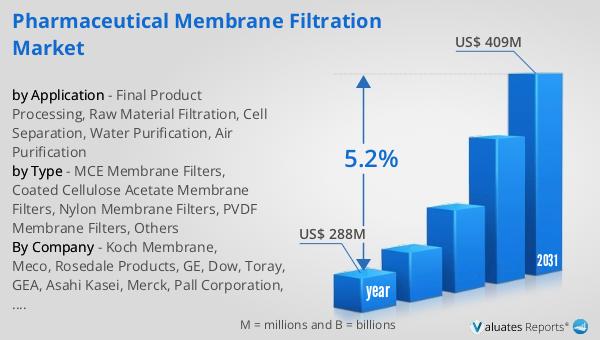

Global Pharmaceutical Membrane Filtration Market Outlook:

In 2024, the global market for Pharmaceutical Membrane Filtration was valued at approximately $288 million. This market is anticipated to expand to a revised size of $409 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.2% over the forecast period. This growth is indicative of the increasing demand for high-quality pharmaceutical products and the critical role that membrane filtration plays in ensuring product purity and safety. In comparison, the broader global pharmaceutical market was valued at $1,475 billion in 2022 and is projected to grow at a CAGR of 5% over the next six years. This growth is driven by factors such as the rising prevalence of chronic diseases, increasing healthcare expenditure, and the development of new and innovative therapies. Meanwhile, the chemical drug market, a significant segment of the pharmaceutical industry, was estimated to grow from $1,005 billion in 2018 to $1,094 billion in 2022. This growth underscores the ongoing demand for chemical-based pharmaceuticals and the importance of membrane filtration in ensuring their quality and safety. As the pharmaceutical industry continues to expand, the role of membrane filtration in maintaining product integrity and compliance with regulatory standards will become increasingly important.

| Report Metric | Details |

| Report Name | Pharmaceutical Membrane Filtration Market |

| Accounted market size in year | US$ 288 million |

| Forecasted market size in 2031 | US$ 409 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Koch Membrane, Meco, Rosedale Products, GE, Dow, Toray, GEA, Asahi Kasei, Merck, Pall Corporation, Sartorius Stedim Biotech Group, Alfa Laval, Graver Technologies, GEA Group, Novasep |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |