What is Global FRP Cooling Tower Market?

The Global FRP Cooling Tower Market refers to the worldwide industry focused on the production, distribution, and utilization of cooling towers made from Fiber Reinforced Plastic (FRP). These cooling towers are essential components in various industrial processes, providing a means to remove excess heat from systems by cooling water through evaporation. FRP cooling towers are favored for their durability, corrosion resistance, and lightweight properties, making them suitable for a wide range of applications. The market encompasses a variety of cooling tower designs, including round and square configurations, each tailored to specific operational needs. As industries continue to expand and modernize, the demand for efficient and reliable cooling solutions like FRP cooling towers is expected to grow. This market is driven by the need for energy-efficient cooling systems, advancements in FRP technology, and the increasing industrialization across the globe. The Global FRP Cooling Tower Market is a dynamic and evolving sector, reflecting broader trends in industrial development and environmental sustainability.

FRP Round Cooling Tower, FRP Square Cooling Tower in the Global FRP Cooling Tower Market:

FRP Round Cooling Towers and FRP Square Cooling Towers are two primary types of cooling towers within the Global FRP Cooling Tower Market, each offering unique benefits and applications. FRP Round Cooling Towers are typically characterized by their circular design, which allows for uniform air distribution and efficient cooling performance. These towers are often used in smaller installations or where space is limited, as their compact design can fit into tighter spaces. The round shape also facilitates easy maintenance and cleaning, as there are no corners where debris can accumulate. Additionally, the aerodynamic design of round towers can enhance airflow, improving overall cooling efficiency. On the other hand, FRP Square Cooling Towers are designed with a rectangular or square footprint, providing a larger surface area for heat exchange. This design is particularly advantageous in larger industrial settings where higher cooling capacities are required. Square cooling towers can be more easily scaled to meet the demands of large-scale operations, making them a popular choice in industries such as power generation and petrochemicals. The modular nature of square towers allows for easy expansion and customization, enabling operators to tailor the cooling system to their specific needs. Both round and square FRP cooling towers benefit from the inherent advantages of FRP materials, including resistance to corrosion, lightweight construction, and long service life. These properties make FRP cooling towers a cost-effective and reliable choice for industries seeking to optimize their cooling processes. The choice between round and square designs often depends on factors such as available space, cooling requirements, and budget considerations. As the Global FRP Cooling Tower Market continues to evolve, manufacturers are innovating to enhance the performance and efficiency of both round and square cooling tower designs. This includes the integration of advanced materials, improved airflow dynamics, and enhanced water distribution systems. By leveraging these innovations, industries can achieve greater energy efficiency, reduced operational costs, and improved environmental sustainability. The ongoing development of FRP cooling tower technology underscores the importance of these systems in supporting industrial growth and environmental stewardship.

Refinery, Chemical Plant, Petrochemical Plant, Thermal Power Station, Other in the Global FRP Cooling Tower Market:

The Global FRP Cooling Tower Market finds extensive usage across various industrial sectors, including refineries, chemical plants, petrochemical plants, thermal power stations, and other industries. In refineries, FRP cooling towers play a crucial role in maintaining optimal temperatures for various processes, such as distillation and cracking. The ability of FRP cooling towers to withstand harsh chemical environments and resist corrosion makes them ideal for refinery applications, where exposure to aggressive chemicals is common. In chemical plants, cooling towers are essential for dissipating heat generated during chemical reactions and maintaining safe operating conditions. The lightweight and durable nature of FRP cooling towers ensures they can handle the demanding conditions of chemical processing, providing reliable and efficient cooling solutions. Petrochemical plants also rely heavily on FRP cooling towers to manage the heat generated during the production of petrochemical products. The versatility and adaptability of FRP cooling towers make them suitable for a wide range of petrochemical processes, from polymer production to refining. In thermal power stations, cooling towers are critical for condensing steam and maintaining efficient power generation. FRP cooling towers offer the advantage of reduced maintenance requirements and long service life, making them a cost-effective choice for power plants seeking to optimize their cooling systems. Beyond these specific industries, FRP cooling towers are also used in various other applications, such as HVAC systems, food and beverage processing, and manufacturing. The adaptability of FRP cooling towers to different operational requirements and environmental conditions underscores their importance in supporting industrial efficiency and sustainability. As industries continue to prioritize energy efficiency and environmental responsibility, the demand for FRP cooling towers is expected to grow, driving further innovation and development in the Global FRP Cooling Tower Market.

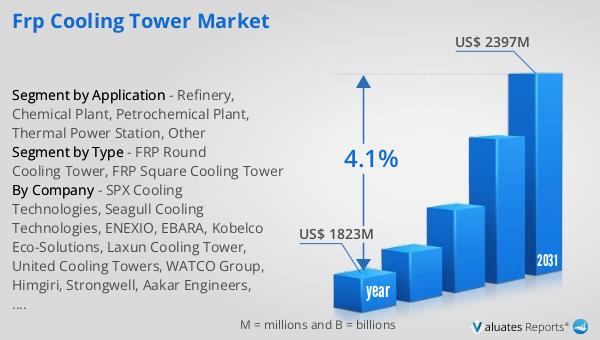

Global FRP Cooling Tower Market Outlook:

The global market for FRP Cooling Towers was valued at $1,823 million in 2024 and is anticipated to expand to a revised size of $2,397 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.1% over the forecast period. This growth trajectory highlights the increasing demand for FRP cooling towers across various industries, driven by the need for efficient and sustainable cooling solutions. The market's expansion is supported by advancements in FRP technology, which enhance the performance and durability of cooling towers, making them more attractive to industrial users. As industries continue to modernize and prioritize energy efficiency, the adoption of FRP cooling towers is expected to rise, contributing to the market's growth. The projected increase in market size underscores the importance of FRP cooling towers in supporting industrial processes and environmental sustainability. With their ability to provide reliable and efficient cooling solutions, FRP cooling towers are poised to play a critical role in the future of industrial cooling.

| Report Metric | Details |

| Report Name | FRP Cooling Tower Market |

| Accounted market size in year | US$ 1823 million |

| Forecasted market size in 2031 | US$ 2397 million |

| CAGR | 4.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SPX Cooling Technologies, Seagull Cooling Technologies, ENEXIO, EBARA, Kobelco Eco-Solutions, Laxun Cooling Tower, United Cooling Towers, WATCO Group, Himgiri, Strongwell, Aakar Engineers, CASE Group, MK Cooling Systems, TIANMA, Artech Cooling Towers, FLUCON, Perfect Cooling Towers, Wetbulb Cooling Towers |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |