What is Global Waterjet Cutting Equipment Market?

The Global Waterjet Cutting Equipment Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries by providing precise and efficient cutting solutions. Waterjet cutting technology uses a high-pressure stream of water, often mixed with abrasive materials, to cut through a wide range of materials, including metals, glass, stone, and composites. This method is highly valued for its ability to produce clean cuts without generating heat, which can alter the properties of the material being cut. The market for waterjet cutting equipment is driven by the increasing demand for precision cutting in industries such as automotive, aerospace, and construction. Additionally, the growing emphasis on sustainability and reducing material waste has further propelled the adoption of waterjet cutting technology. As industries continue to seek innovative solutions to enhance productivity and reduce operational costs, the Global Waterjet Cutting Equipment Market is expected to witness significant growth, offering advanced cutting solutions that cater to diverse industrial needs.

3D Waterjet Cutting, Micro Waterjet Cutting, Robotic Waterjet in the Global Waterjet Cutting Equipment Market:

3D Waterjet Cutting, Micro Waterjet Cutting, and Robotic Waterjet Cutting are three specialized segments within the Global Waterjet Cutting Equipment Market, each offering unique advantages and applications. 3D Waterjet Cutting is a sophisticated technique that allows for the cutting of complex shapes and contours in three dimensions. This capability is particularly beneficial in industries such as aerospace and automotive, where precision and intricate designs are paramount. By utilizing advanced software and multi-axis cutting heads, 3D waterjet cutting can produce parts with high accuracy and minimal material waste, making it an ideal choice for manufacturers seeking to optimize their production processes. On the other hand, Micro Waterjet Cutting is a specialized form of waterjet cutting that focuses on achieving extremely fine and precise cuts. This technique is essential for industries that require intricate detailing, such as electronics and medical device manufacturing. Micro waterjet cutting can achieve tolerances as tight as a few microns, allowing for the production of small, delicate components with exceptional precision. The ability to cut without generating heat also ensures that the material properties remain unchanged, which is crucial for maintaining the integrity of sensitive materials. Robotic Waterjet Cutting combines the flexibility and precision of waterjet technology with the automation and efficiency of robotics. This integration allows for the automation of complex cutting tasks, reducing the need for manual intervention and increasing production efficiency. Robotic waterjet cutting is widely used in industries such as automotive and aerospace, where large volumes of parts need to be cut with consistent quality and precision. The use of robots also enables manufacturers to achieve higher throughput and reduce labor costs, making it a cost-effective solution for high-volume production environments. Overall, these specialized waterjet cutting techniques offer significant advantages in terms of precision, efficiency, and versatility, catering to the diverse needs of various industries and driving the growth of the Global Waterjet Cutting Equipment Market.

General Metal Fabrication, Construction, Heavy Metal Fabrication, Shipbuilding & Offshore, Automotive, Others in the Global Waterjet Cutting Equipment Market:

The Global Waterjet Cutting Equipment Market finds extensive applications across various industries, including General Metal Fabrication, Construction, Heavy Metal Fabrication, Shipbuilding & Offshore, Automotive, and others. In General Metal Fabrication, waterjet cutting is highly valued for its ability to cut a wide range of metals with precision and minimal material waste. This capability is essential for fabricators who need to produce parts with tight tolerances and high-quality finishes. The versatility of waterjet cutting also allows fabricators to work with different materials, including stainless steel, aluminum, and titanium, making it a preferred choice for custom metal fabrication projects. In the Construction industry, waterjet cutting is used for cutting materials such as stone, glass, and concrete. The ability to cut without generating heat or dust makes waterjet cutting an ideal solution for construction projects that require precise cuts and minimal environmental impact. This technology is particularly useful for creating intricate designs in architectural elements, such as facades and decorative panels. Heavy Metal Fabrication benefits from waterjet cutting's ability to handle thick and dense materials with ease. This capability is crucial for industries that require the fabrication of large and heavy components, such as mining and heavy machinery manufacturing. Waterjet cutting provides a cost-effective and efficient solution for cutting thick metal plates and reducing material waste. In the Shipbuilding & Offshore industry, waterjet cutting is used for cutting metal plates and other materials used in the construction of ships and offshore structures. The precision and efficiency of waterjet cutting help shipbuilders achieve high-quality cuts and reduce production time, which is essential for meeting tight project deadlines. The Automotive industry is one of the largest users of waterjet cutting technology, with applications ranging from cutting interior components to trimming metal and composite parts. The ability to produce precise cuts without affecting the material properties is crucial for automotive manufacturers who need to maintain the structural integrity and performance of their components. Additionally, waterjet cutting's versatility allows manufacturers to work with a variety of materials, including metals, plastics, and composites, making it an ideal solution for automotive production. Other industries, such as aerospace, electronics, and medical device manufacturing, also benefit from the precision and versatility of waterjet cutting technology. The ability to achieve intricate cuts and maintain material integrity is essential for producing high-quality components in these industries. Overall, the Global Waterjet Cutting Equipment Market plays a vital role in enhancing the efficiency and productivity of various industries by providing advanced cutting solutions that cater to their specific needs.

Global Waterjet Cutting Equipment Market Outlook:

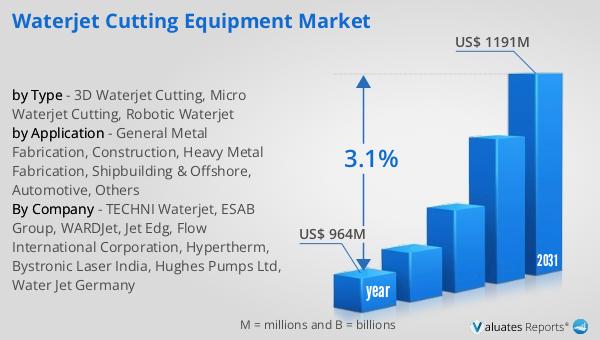

The global market for Waterjet Cutting Equipment was valued at approximately $964 million in 2024, and it is anticipated to grow to a revised size of around $1,191 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.1% over the forecast period. North America stands out as the largest market, holding a share exceeding 30%, which underscores the region's significant demand and adoption of waterjet cutting technology. This demand is driven by the region's robust industrial base and the need for precise and efficient cutting solutions across various sectors. The automotive industry emerges as the most prominent application area for waterjet cutting equipment, accounting for over 36% of the market share. This substantial share highlights the critical role that waterjet cutting plays in automotive manufacturing, where precision and material integrity are paramount. The technology's ability to cut a wide range of materials without generating heat or altering material properties makes it an ideal choice for automotive manufacturers seeking to enhance production efficiency and product quality. As industries continue to evolve and seek innovative solutions to meet their cutting needs, the Global Waterjet Cutting Equipment Market is poised for steady growth, driven by advancements in technology and increasing demand across diverse applications.

| Report Metric | Details |

| Report Name | Waterjet Cutting Equipment Market |

| Accounted market size in year | US$ 964 million |

| Forecasted market size in 2031 | US$ 1191 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TECHNI Waterjet, ESAB Group, WARDJet, Jet Edg, Flow International Corporation, Hypertherm, Bystronic Laser India, Hughes Pumps Ltd, Water Jet Germany |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |