What is Global Instrumentation Valves Market?

The Global Instrumentation Valves Market is a crucial segment within the broader industrial valves industry, focusing on the production and distribution of valves used in various instrumentation systems. These valves are essential components in controlling and regulating the flow of liquids and gases in numerous industrial applications. They are designed to withstand high pressure and temperature conditions, ensuring the safe and efficient operation of complex systems. The market encompasses a wide range of valve types, including ball valves, needle valves, check valves, manifold valves, and ultraclean valves, each serving specific functions and applications. The demand for instrumentation valves is driven by their critical role in industries such as oil and gas, healthcare, chemicals, and energy, where precise control and reliability are paramount. As industries continue to expand and modernize, the need for advanced instrumentation valves that offer enhanced performance and durability is expected to grow. This market is characterized by technological advancements, with manufacturers focusing on developing innovative solutions to meet the evolving needs of various sectors. Overall, the Global Instrumentation Valves Market plays a vital role in ensuring the smooth operation of industrial processes worldwide.

Ball Valves, Needle Valves, Check Valves, Manifold Valves, Ultraclean Valves, Others in the Global Instrumentation Valves Market:

Ball valves are a type of instrumentation valve that uses a spherical disc to control the flow of fluids. They are known for their durability and ability to provide a tight seal, making them ideal for applications where leakage prevention is critical. Ball valves are commonly used in industries such as oil and gas, chemical processing, and water treatment. Needle valves, on the other hand, are designed for precise flow control. They feature a slender, tapered point at the end of a valve stem, which allows for fine adjustments to the flow rate. This makes needle valves suitable for applications requiring accurate flow regulation, such as in laboratory settings and instrumentation systems. Check valves are another important type of instrumentation valve, designed to allow fluid to flow in one direction only. They prevent backflow, ensuring that the system operates efficiently and safely. Check valves are widely used in various industries, including oil and gas, water treatment, and chemical processing. Manifold valves are used to connect multiple valves in a single unit, allowing for the control of multiple flow paths. They are commonly used in applications where space is limited, and multiple flow paths need to be managed simultaneously. Ultraclean valves are designed for use in environments where contamination must be minimized, such as in semiconductor manufacturing and pharmaceutical production. These valves are constructed from materials that resist corrosion and contamination, ensuring the purity of the process fluids. Other types of instrumentation valves include diaphragm valves, which use a flexible diaphragm to control flow, and pinch valves, which use a pinching mechanism to regulate flow. Each type of valve offers unique advantages and is suited to specific applications, making the Global Instrumentation Valves Market a diverse and dynamic industry.

Oil & Gas, Healthcare, Chemicals, Pulp & Paper, Food & Beverages, Semiconductor, Energy & Power, Others in the Global Instrumentation Valves Market:

The Global Instrumentation Valves Market finds extensive usage across a variety of industries, each with its unique requirements and challenges. In the oil and gas sector, instrumentation valves are critical for controlling the flow of crude oil, natural gas, and other fluids throughout the extraction, refining, and distribution processes. These valves must withstand harsh environmental conditions and high pressures, ensuring the safe and efficient operation of oil and gas facilities. In the healthcare industry, instrumentation valves are used in medical devices and equipment, where precise control of fluids and gases is essential for patient safety and effective treatment. Valves in this sector must meet stringent regulatory standards and are often designed for easy sterilization and maintenance. The chemical industry relies on instrumentation valves to manage the flow of various chemicals and compounds, often under extreme temperature and pressure conditions. These valves must be resistant to corrosion and chemical attack, ensuring the integrity of the process and the safety of personnel. In the pulp and paper industry, instrumentation valves are used to control the flow of water, chemicals, and pulp during the manufacturing process. These valves must be durable and reliable, as they operate in challenging environments with abrasive materials. The food and beverage industry uses instrumentation valves to manage the flow of ingredients and products, ensuring hygiene and quality throughout the production process. Valves in this sector must comply with strict food safety regulations and are often designed for easy cleaning and maintenance. In the semiconductor industry, ultraclean valves are essential for maintaining the purity of process gases and liquids, preventing contamination of sensitive electronic components. The energy and power sector relies on instrumentation valves to control the flow of steam, water, and other fluids in power generation and distribution systems. These valves must be robust and reliable, capable of withstanding high pressures and temperatures. Other industries, such as water treatment and pharmaceuticals, also depend on instrumentation valves for precise flow control and system integrity. Overall, the Global Instrumentation Valves Market plays a vital role in ensuring the efficient and safe operation of a wide range of industrial processes.

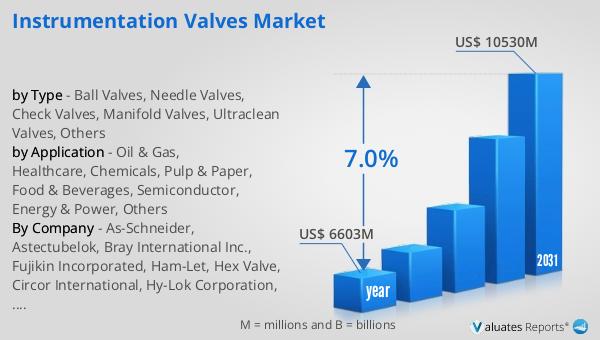

Global Instrumentation Valves Market Outlook:

In 2024, the global market for instrumentation valves was valued at approximately $6,603 million. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach an estimated value of $10,530 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 7.0% throughout the forecast period. The increasing demand for instrumentation valves across various industries, including oil and gas, healthcare, chemicals, and energy, is a key driver of this market expansion. As industries continue to modernize and adopt advanced technologies, the need for reliable and efficient flow control solutions becomes increasingly important. Instrumentation valves play a crucial role in ensuring the safe and efficient operation of complex systems, making them indispensable components in many industrial applications. The market's growth is also supported by ongoing technological advancements, with manufacturers focusing on developing innovative valve solutions that offer enhanced performance and durability. As a result, the Global Instrumentation Valves Market is poised for continued expansion, driven by the increasing demand for high-quality valves that meet the evolving needs of various industries.

| Report Metric | Details |

| Report Name | Instrumentation Valves Market |

| Accounted market size in year | US$ 6603 million |

| Forecasted market size in 2031 | US$ 10530 million |

| CAGR | 7.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | As-Schneider, Astectubelok, Bray International Inc., Fujikin Incorporated, Ham-Let, Hex Valve, Circor International, Hy-Lok Corporation, Oliver Valves, Parker Hannifin, Safelok, SSP Fittings, Swagelok, Braeco, Dwyer Instruments, Fitok, Tylok International |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |