What is Global Double-Acting Pneumatic Cylinder Market?

The Global Double-Acting Pneumatic Cylinder Market is a significant segment within the broader pneumatic systems industry, which plays a crucial role in various industrial applications. Double-acting pneumatic cylinders are devices that use compressed air to produce a force in a reciprocating linear motion. Unlike single-acting cylinders, which use air pressure to move in one direction and a spring to return, double-acting cylinders use air pressure to move in both directions. This feature makes them highly efficient and versatile for applications requiring precise control and consistent force. The market for these cylinders is driven by their widespread use in automation, manufacturing, and other industrial processes where reliability and efficiency are paramount. As industries continue to automate and seek energy-efficient solutions, the demand for double-acting pneumatic cylinders is expected to grow. These cylinders are integral in sectors such as automotive, aerospace, and material handling, where they contribute to the smooth operation of machinery and equipment. The global market is characterized by technological advancements, increasing adoption of automation, and a focus on energy efficiency, which are key factors influencing its growth trajectory.

Rotary Pneumatic Cylinder, Semi-Rotary Pneumatic Cylinder in the Global Double-Acting Pneumatic Cylinder Market:

Rotary pneumatic cylinders and semi-rotary pneumatic cylinders are specialized types of actuators within the Global Double-Acting Pneumatic Cylinder Market, each serving unique functions in various industrial applications. Rotary pneumatic cylinders are designed to convert compressed air energy into rotary motion, making them ideal for applications requiring rotational movement. These cylinders are commonly used in machinery that requires precise angular positioning, such as in the automation of assembly lines, packaging machines, and material handling systems. They offer advantages like high torque output, compact design, and the ability to operate in harsh environments, which makes them suitable for industries like automotive and manufacturing. On the other hand, semi-rotary pneumatic cylinders provide limited angular movement, typically less than 360 degrees. They are used in applications where a full rotation is not necessary, such as in clamping, indexing, and positioning tasks. These cylinders are valued for their ability to deliver controlled and repeatable motion, which is essential in processes like welding, cutting, and assembly. Both rotary and semi-rotary pneumatic cylinders are integral to the automation of industrial processes, contributing to increased efficiency, precision, and safety. The demand for these cylinders is driven by the need for reliable and efficient motion control solutions in various sectors, including automotive, aerospace, and electronics. As industries continue to embrace automation and seek energy-efficient solutions, the market for rotary and semi-rotary pneumatic cylinders is expected to grow. Technological advancements, such as the integration of sensors and smart technologies, are further enhancing the capabilities of these cylinders, making them more adaptable to the evolving needs of modern industries. The global market for these cylinders is characterized by a focus on innovation, quality, and performance, with manufacturers striving to meet the diverse requirements of their customers. As a result, the market is witnessing increased competition, with companies investing in research and development to introduce new and improved products. The growing emphasis on sustainability and energy efficiency is also influencing the market, as industries seek to reduce their carbon footprint and operational costs. Overall, the Global Double-Acting Pneumatic Cylinder Market, including rotary and semi-rotary pneumatic cylinders, is poised for growth, driven by the increasing adoption of automation and the need for efficient motion control solutions in various industrial applications.

Printing, Robot, Automatic Control, Other in the Global Double-Acting Pneumatic Cylinder Market:

The Global Double-Acting Pneumatic Cylinder Market finds extensive usage in various areas, including printing, robotics, automatic control, and other industrial applications. In the printing industry, double-acting pneumatic cylinders are used to control the movement of printing plates, rollers, and other components, ensuring precise and consistent printing quality. They provide the necessary force and motion control required for high-speed printing operations, contributing to increased productivity and efficiency. In robotics, these cylinders are used to actuate robotic arms and grippers, enabling precise and controlled movement. They play a crucial role in tasks such as pick-and-place operations, assembly, and material handling, where accuracy and repeatability are essential. The use of double-acting pneumatic cylinders in robotics enhances the performance and reliability of robotic systems, making them indispensable in modern manufacturing processes. In automatic control systems, these cylinders are used to regulate the movement of various components, such as valves, dampers, and actuators. They provide the necessary force and motion control required for precise and efficient operation, contributing to improved system performance and energy efficiency. The versatility and reliability of double-acting pneumatic cylinders make them suitable for a wide range of automatic control applications, from HVAC systems to industrial automation. In addition to these areas, double-acting pneumatic cylinders are used in various other industrial applications, such as material handling, packaging, and assembly. They provide the necessary force and motion control required for efficient and reliable operation, contributing to increased productivity and reduced downtime. The demand for these cylinders is driven by the need for efficient and reliable motion control solutions in various industries, including automotive, aerospace, and electronics. As industries continue to embrace automation and seek energy-efficient solutions, the market for double-acting pneumatic cylinders is expected to grow. Technological advancements, such as the integration of sensors and smart technologies, are further enhancing the capabilities of these cylinders, making them more adaptable to the evolving needs of modern industries. Overall, the Global Double-Acting Pneumatic Cylinder Market is poised for growth, driven by the increasing adoption of automation and the need for efficient motion control solutions in various industrial applications.

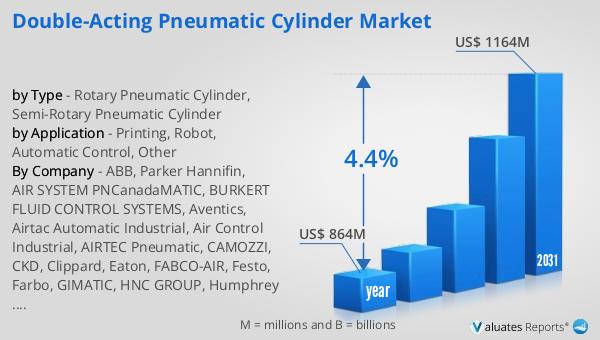

Global Double-Acting Pneumatic Cylinder Market Outlook:

The global market for double-acting pneumatic cylinders was valued at approximately $864 million in 2024. This valuation reflects the significant demand and widespread application of these cylinders across various industries. As industries continue to evolve and seek more efficient and reliable motion control solutions, the market for double-acting pneumatic cylinders is projected to grow. By 2031, the market is expected to reach a revised size of around $1,164 million, indicating a steady growth trajectory. This growth is driven by a compound annual growth rate (CAGR) of 4.4% during the forecast period. The increasing adoption of automation, technological advancements, and the focus on energy efficiency are key factors contributing to this growth. As industries continue to automate and seek energy-efficient solutions, the demand for double-acting pneumatic cylinders is expected to grow. These cylinders are integral in sectors such as automotive, aerospace, and material handling, where they contribute to the smooth operation of machinery and equipment. The global market is characterized by technological advancements, increasing adoption of automation, and a focus on energy efficiency, which are key factors influencing its growth trajectory. The market is witnessing increased competition, with companies investing in research and development to introduce new and improved products. The growing emphasis on sustainability and energy efficiency is also influencing the market, as industries seek to reduce their carbon footprint and operational costs. Overall, the Global Double-Acting Pneumatic Cylinder Market is poised for growth, driven by the increasing adoption of automation and the need for efficient motion control solutions in various industrial applications.

| Report Metric | Details |

| Report Name | Double-Acting Pneumatic Cylinder Market |

| Accounted market size in year | US$ 864 million |

| Forecasted market size in 2031 | US$ 1164 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABB, Parker Hannifin, AIR SYSTEM PNCanadaMATIC, BURKERT FLUID CONTROL SYSTEMS, Aventics, Airtac Automatic Industrial, Air Control Industrial, AIRTEC Pneumatic, CAMOZZI, CKD, Clippard, Eaton, FABCO-AIR, Festo, Farbo, GIMATIC, HNC GROUP, Humphrey Products, Ningbo Pneumission Pneumatic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |