What is Global Electric Vacuum Furnace Market?

The Global Electric Vacuum Furnace Market is a specialized segment within the broader industrial furnace industry, focusing on furnaces that operate under vacuum conditions to process materials. These furnaces are essential in industries where high precision and purity are required, such as aerospace, automotive, and electronics. The vacuum environment minimizes contamination and oxidation, allowing for the production of high-quality materials. Electric vacuum furnaces are used for various applications, including heat treatment, brazing, sintering, and annealing. They are designed to handle a wide range of materials, including metals, ceramics, and composites. The market is driven by the increasing demand for advanced materials and the need for efficient and environmentally friendly manufacturing processes. Technological advancements and the growing emphasis on energy efficiency are also contributing to the market's growth. As industries continue to evolve and demand more sophisticated materials, the Global Electric Vacuum Furnace Market is expected to expand, offering new opportunities for innovation and development. The market's growth is supported by the continuous advancements in furnace technology, which enhance performance, reduce energy consumption, and improve the quality of the end products.

Electromagnetic Heat Source, Resistance Heat Source, Arc Heat Source in the Global Electric Vacuum Furnace Market:

In the Global Electric Vacuum Furnace Market, various heat sources are employed to achieve the desired thermal processing conditions. One of the primary heat sources is the Electromagnetic Heat Source, which utilizes electromagnetic fields to generate heat within the furnace. This method is highly efficient and allows for precise temperature control, making it ideal for applications requiring uniform heating. Electromagnetic heating is particularly beneficial in processes where rapid heating and cooling cycles are necessary, as it can quickly adjust to the required temperatures. Another common heat source is the Resistance Heat Source, which relies on electrical resistance to produce heat. This method involves passing an electric current through resistive elements, which then generate heat due to their resistance. Resistance heating is known for its simplicity and reliability, making it a popular choice for many industrial applications. It provides consistent and controllable heat, which is crucial for processes that demand high precision and repeatability. The Arc Heat Source is another significant method used in electric vacuum furnaces. This technique involves creating an electric arc between electrodes, which generates intense heat. Arc heating is particularly useful for processes that require extremely high temperatures, such as melting and refining metals. It is also advantageous for its ability to rapidly reach and maintain high temperatures, making it suitable for applications that demand quick thermal processing. Each of these heat sources offers unique advantages and is selected based on the specific requirements of the application. The choice of heat source can significantly impact the efficiency, quality, and cost-effectiveness of the thermal processing operation. As the Global Electric Vacuum Furnace Market continues to grow, the development and optimization of these heat sources remain a critical focus for manufacturers and researchers. Innovations in heat source technology are expected to enhance the performance and capabilities of electric vacuum furnaces, enabling them to meet the evolving demands of various industries.

Metallurgical Industry, Chemical Industry, Other in the Global Electric Vacuum Furnace Market:

The Global Electric Vacuum Furnace Market finds extensive usage across several industries, each with its unique requirements and applications. In the Metallurgical Industry, electric vacuum furnaces are crucial for processes such as heat treatment, sintering, and brazing of metals. These furnaces provide a controlled environment that minimizes oxidation and contamination, ensuring the production of high-quality metal components. The ability to precisely control temperature and atmosphere makes electric vacuum furnaces ideal for processing advanced alloys and high-performance materials used in aerospace, automotive, and defense applications. In the Chemical Industry, electric vacuum furnaces are used for processes that require high purity and controlled environments, such as the production of specialty chemicals and materials. The vacuum conditions help prevent unwanted reactions and contamination, ensuring the integrity and quality of the final products. These furnaces are also employed in the development of new chemical compounds and materials, where precise thermal processing is essential. Beyond the metallurgical and chemical industries, electric vacuum furnaces are utilized in various other sectors, including electronics, energy, and medical device manufacturing. In the electronics industry, they are used for processes like annealing and diffusion, which are critical for the production of semiconductors and other electronic components. The energy sector employs electric vacuum furnaces for the development and processing of materials used in renewable energy technologies, such as solar panels and fuel cells. In the medical field, these furnaces are used for the production of high-purity materials and components for medical devices and implants. The versatility and precision of electric vacuum furnaces make them indispensable tools across these diverse industries, driving their demand and adoption in the global market.

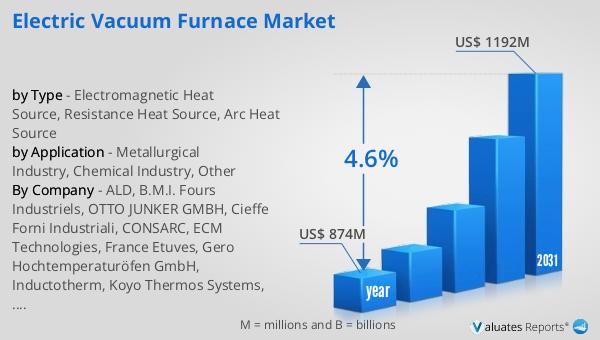

Global Electric Vacuum Furnace Market Outlook:

The global market for Electric Vacuum Furnace was valued at approximately $874 million in 2024, with projections indicating a growth to around $1,192 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.6% over the forecast period. This upward trend is indicative of the increasing demand for electric vacuum furnaces across various industries, driven by the need for advanced materials and efficient manufacturing processes. The market's expansion is supported by technological advancements that enhance the performance and capabilities of these furnaces, making them more efficient and environmentally friendly. As industries continue to evolve and require more sophisticated materials, the demand for electric vacuum furnaces is expected to rise, offering new opportunities for innovation and development. The market's growth is also fueled by the continuous advancements in furnace technology, which improve energy efficiency and reduce operational costs. These factors, combined with the growing emphasis on sustainability and environmental responsibility, are expected to drive the market's expansion in the coming years. The increasing adoption of electric vacuum furnaces in emerging markets and the development of new applications are also contributing to the market's growth, making it a dynamic and evolving sector with significant potential for future development.

| Report Metric | Details |

| Report Name | Electric Vacuum Furnace Market |

| Accounted market size in year | US$ 874 million |

| Forecasted market size in 2031 | US$ 1192 million |

| CAGR | 4.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ALD, B.M.I. Fours Industriels, OTTO JUNKER GMBH, Cieffe Forni Industriali, CONSARC, ECM Technologies, France Etuves, Gero Hochtemperaturöfen GmbH, Inductotherm, Koyo Thermos Systems, Materials Research Furnaces, Memmert, Nabertherm, PINK GmbH Thermosysteme |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |