What is Global Pneumatic Pinch Valve Market?

The Global Pneumatic Pinch Valve Market is a specialized segment within the broader valve industry, focusing on devices that control the flow of various media through a flexible tube or sleeve. These valves are particularly valued for their ability to handle abrasive, corrosive, and viscous materials without causing damage to the valve itself. The pneumatic pinch valve operates by using compressed air to pinch the sleeve, effectively stopping or regulating the flow of the media. This design minimizes wear and tear, making it ideal for applications where traditional valves might fail. The market for these valves is driven by their versatility and efficiency in handling challenging materials across various industries. As industries continue to seek reliable and low-maintenance solutions for fluid control, the demand for pneumatic pinch valves is expected to grow. Their ability to provide a tight seal and handle a wide range of temperatures and pressures makes them a preferred choice in sectors such as mining, wastewater treatment, and food processing. The global market is characterized by a mix of established players and emerging companies, all striving to innovate and improve the performance and durability of these valves.

Regulating Pinch Valve, Control Pinch Valve, Shut-Off Pinch Valve in the Global Pneumatic Pinch Valve Market:

In the Global Pneumatic Pinch Valve Market, there are several types of pinch valves, each serving distinct functions: regulating pinch valves, control pinch valves, and shut-off pinch valves. Regulating pinch valves are designed to modulate the flow of media with precision. They are often used in applications where maintaining a specific flow rate is crucial, such as in chemical processing or water treatment facilities. These valves can adjust the flow by varying the degree of pinching applied to the sleeve, allowing for fine-tuned control over the media passing through. Control pinch valves, on the other hand, are engineered to manage the flow of media in a more automated manner. They are typically integrated into systems that require real-time adjustments based on feedback from sensors or control systems. This makes them ideal for complex industrial processes where conditions can change rapidly, and precise control is necessary to maintain efficiency and safety. Shut-off pinch valves are primarily used to completely stop the flow of media. They are often employed in emergency situations or maintenance operations where a quick and reliable shut-off is required. The design of these valves ensures a tight seal, preventing leaks and ensuring the safety of the system. Each type of pinch valve offers unique advantages, and their selection depends on the specific requirements of the application. In the global market, manufacturers are continually innovating to enhance the performance and reliability of these valves, addressing the diverse needs of industries ranging from pharmaceuticals to mining. The versatility of pneumatic pinch valves, combined with their ability to handle challenging materials, makes them an essential component in modern industrial processes. As industries evolve and demand more efficient and reliable fluid control solutions, the role of these valves is expected to become even more significant.

Metallurgical Industry, Chemical Industry, Electric Power Industry, Food Industry, Other in the Global Pneumatic Pinch Valve Market:

The Global Pneumatic Pinch Valve Market finds extensive usage across various industries due to its unique design and functionality. In the metallurgical industry, these valves are crucial for handling abrasive slurries and corrosive materials. The ability of pneumatic pinch valves to provide a tight seal and withstand harsh conditions makes them ideal for processes such as ore processing and metal extraction. Their low maintenance requirements and durability are significant advantages in environments where equipment is subjected to extreme wear and tear. In the chemical industry, pneumatic pinch valves are used to control the flow of aggressive chemicals and viscous fluids. Their design minimizes the risk of leaks and contamination, ensuring the safety and integrity of chemical processes. These valves are particularly useful in applications where precise flow control is necessary, such as in the production of pharmaceuticals and specialty chemicals. The electric power industry also benefits from the use of pneumatic pinch valves, particularly in the management of cooling systems and the handling of ash and slurry. Their ability to operate reliably under high temperatures and pressures makes them suitable for power plants and other energy-related facilities. In the food industry, pneumatic pinch valves are employed to handle food products and ingredients, ensuring hygiene and preventing contamination. Their smooth operation and easy cleaning make them ideal for applications where cleanliness is paramount. Additionally, these valves are used in other industries such as wastewater treatment, mining, and pulp and paper, where their ability to handle challenging materials and provide reliable flow control is highly valued. The versatility and efficiency of pneumatic pinch valves make them a preferred choice for industries seeking robust and low-maintenance solutions for fluid control.

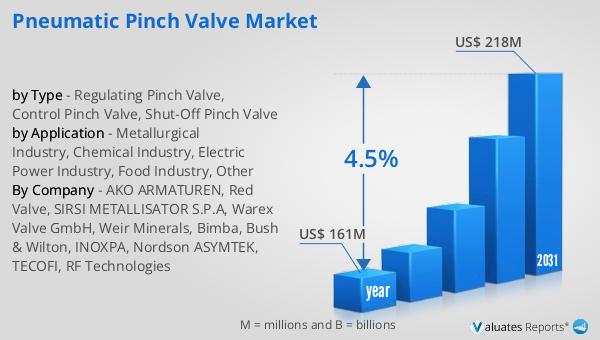

Global Pneumatic Pinch Valve Market Outlook:

The global market for pneumatic pinch valves was valued at approximately $161 million in 2024. It is anticipated to grow steadily, reaching an estimated size of $218 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.5% over the forecast period. The increasing demand for efficient and reliable fluid control solutions across various industries is a key driver of this market expansion. Industries such as mining, chemical processing, and food production are continually seeking advanced technologies to enhance their operations, and pneumatic pinch valves offer a viable solution. Their ability to handle abrasive, corrosive, and viscous materials with minimal maintenance makes them an attractive option for businesses looking to optimize their processes. Additionally, the ongoing trend towards automation and smart manufacturing is expected to further boost the demand for these valves, as they can be easily integrated into automated systems. As the market continues to evolve, manufacturers are focusing on innovation and product development to meet the diverse needs of their customers. This includes improving the durability and performance of pinch valves, as well as expanding their application range. The global pneumatic pinch valve market is poised for significant growth, driven by the increasing need for efficient and reliable fluid control solutions in various industries.

| Report Metric | Details |

| Report Name | Pneumatic Pinch Valve Market |

| Accounted market size in year | US$ 161 million |

| Forecasted market size in 2031 | US$ 218 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AKO ARMATUREN, Red Valve, SIRSI METALLISATOR S.P.A, Warex Valve GmbH, Weir Minerals, Bimba, Bush & Wilton, INOXPA, Nordson ASYMTEK, TECOFI, RF Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |