What is Global Food Dosing Pump Market?

The Global Food Dosing Pump Market is a specialized segment within the broader industrial equipment sector, focusing on the precise delivery of food ingredients and additives. These pumps are essential in ensuring that the right amount of a substance is added to food products during manufacturing, which is crucial for maintaining quality, taste, and safety standards. The market encompasses a variety of pump types, each designed to handle different viscosities and types of food substances, from liquids to semi-solids. The demand for food dosing pumps is driven by the increasing need for automation in food processing, which helps in reducing human error and enhancing efficiency. Additionally, the growing emphasis on food safety and hygiene has led to the adoption of advanced dosing technologies that minimize contamination risks. As the global food industry continues to expand, the food dosing pump market is expected to grow, driven by innovations in pump technology and the increasing complexity of food products that require precise ingredient dosing. This market is characterized by a diverse range of players, from large multinational corporations to specialized local manufacturers, all competing to provide the most efficient and reliable dosing solutions.

Electric Food Dosing Pump, Pneumatic Food Dosing Pump in the Global Food Dosing Pump Market:

Electric Food Dosing Pumps and Pneumatic Food Dosing Pumps are two primary types of pumps used in the Global Food Dosing Pump Market, each with distinct features and applications. Electric food dosing pumps are powered by electricity and are known for their precision and control. They are often used in applications where exact dosing is critical, such as in the production of beverages, sauces, and other liquid-based food products. These pumps can be programmed to deliver specific amounts of ingredients, ensuring consistency and reducing waste. Electric pumps are also favored for their ability to handle a wide range of viscosities, making them versatile tools in food processing. On the other hand, pneumatic food dosing pumps operate using compressed air and are typically used in environments where electricity might pose a risk, such as in explosive atmospheres or where water and electricity could create hazards. Pneumatic pumps are valued for their simplicity and durability, often requiring less maintenance than their electric counterparts. They are particularly useful in applications involving thicker substances or where a robust, reliable pump is needed to handle challenging conditions. Both types of pumps play a crucial role in the food industry, helping manufacturers maintain high standards of quality and efficiency. The choice between electric and pneumatic pumps often depends on the specific requirements of the production process, including the type of food product, the production environment, and the desired level of automation. As technology advances, both electric and pneumatic food dosing pumps are becoming more sophisticated, with features such as remote monitoring and control, which further enhance their utility in modern food processing facilities. The ongoing development of these pumps is driven by the need for greater precision, efficiency, and safety in food manufacturing, reflecting broader trends in the industry towards automation and digitalization. As a result, manufacturers are continually innovating to meet the evolving demands of the food industry, ensuring that their pumps can handle the complexities of modern food production while maintaining the highest standards of quality and safety.

Drinks, Dairy Products, Other in the Global Food Dosing Pump Market:

The Global Food Dosing Pump Market finds extensive usage in various areas, including drinks, dairy products, and other food categories, each with unique requirements and challenges. In the drinks sector, dosing pumps are essential for adding precise amounts of flavorings, colorings, and preservatives to beverages. This precision is crucial for maintaining the consistency and taste of the final product, which is vital for brand reputation and consumer satisfaction. Dosing pumps in this sector must handle a wide range of liquid viscosities and ensure that ingredients are mixed uniformly. In the dairy industry, dosing pumps are used to add cultures, enzymes, and other additives to products like cheese, yogurt, and milk. The accuracy of dosing is critical in dairy processing, as even slight variations can affect the texture, taste, and shelf life of the products. Dosing pumps help maintain the delicate balance required in dairy production, ensuring that products meet stringent quality standards. Beyond drinks and dairy, dosing pumps are used in a variety of other food applications, such as in the production of sauces, dressings, and baked goods. In these areas, pumps must be capable of handling thicker substances and ensuring that ingredients are evenly distributed throughout the product. The versatility of dosing pumps makes them indispensable in food manufacturing, where they contribute to efficiency, consistency, and quality control. As the food industry continues to evolve, the demand for advanced dosing solutions is expected to grow, driven by the need for greater precision and automation in food processing. This growth is supported by technological advancements that enable pumps to handle increasingly complex formulations and production processes. Overall, the Global Food Dosing Pump Market plays a vital role in ensuring that food products are produced to the highest standards, meeting consumer expectations and regulatory requirements.

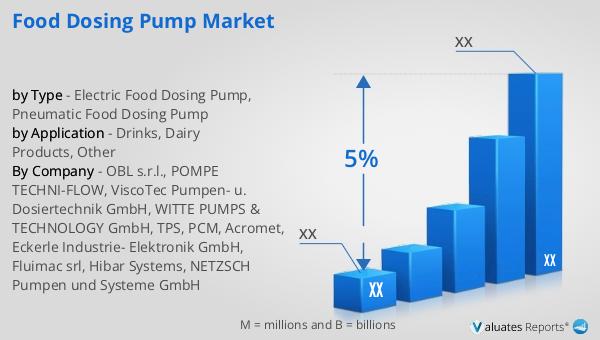

Global Food Dosing Pump Market Outlook:

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, with projections indicating a steady growth rate of 5% annually over the next six years. This growth reflects the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, the rise of chronic diseases, and advancements in medical technology. In contrast, the chemical drug market, a significant subset of the pharmaceutical industry, has shown a more modest growth trajectory. It was estimated to grow from 1,005 billion USD in 2018 to 1,094 billion USD by 2022. This indicates a slower growth rate compared to the broader pharmaceutical market, possibly due to the increasing focus on biologics and personalized medicine, which are gaining traction as alternatives to traditional chemical drugs. The dynamics within these markets highlight the evolving landscape of the pharmaceutical industry, where innovation and adaptation are key to meeting the changing needs of healthcare providers and patients. As the industry continues to evolve, companies are investing in research and development to create more effective and targeted therapies, which are expected to drive future growth and transformation in the market.

| Report Metric | Details |

| Report Name | Food Dosing Pump Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | OBL s.r.l., POMPE TECHNI-FLOW, ViscoTec Pumpen- u. Dosiertechnik GmbH, WITTE PUMPS & TECHNOLOGY GmbH, TPS, PCM, Acromet, Eckerle Industrie- Elektronik GmbH, Fluimac srl, Hibar Systems, NETZSCH Pumpen und Systeme GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |