What is Global Dicing Film Market?

The Global Dicing Film Market is a specialized segment within the broader materials industry, focusing on the production and distribution of films used in the semiconductor manufacturing process. Dicing films are essential in the semiconductor industry as they provide a protective layer during the dicing process, where semiconductor wafers are cut into individual chips. These films ensure that the delicate semiconductor materials are not damaged during cutting, which is crucial for maintaining the integrity and performance of the final electronic components. The market for dicing films is driven by the increasing demand for semiconductors in various applications, including consumer electronics, automotive, and industrial electronics. As technology advances, the need for more precise and efficient dicing processes grows, further fueling the demand for high-quality dicing films. The market is characterized by continuous innovation, with manufacturers striving to develop films that offer better adhesion, thermal resistance, and ease of removal. This dynamic market is poised for growth as the semiconductor industry continues to expand, driven by the proliferation of smart devices, the Internet of Things (IoT), and advancements in artificial intelligence and machine learning technologies.

Non-Conductive Type, Conductive Type in the Global Dicing Film Market:

In the Global Dicing Film Market, two primary types of films are utilized: Non-Conductive Type and Conductive Type. Non-Conductive Dicing Films are primarily used in applications where electrical insulation is crucial. These films are designed to prevent any electrical interference during the dicing process, making them ideal for use in sensitive electronic components where maintaining electrical integrity is paramount. Non-Conductive Films are typically made from materials that do not conduct electricity, such as certain polymers, which provide a stable and reliable barrier during the dicing process. These films are particularly important in the production of semiconductor devices used in consumer electronics, where even minor electrical interference can lead to significant performance issues. On the other hand, Conductive Dicing Films are used in applications where electrical conductivity is required. These films are designed to dissipate static electricity that can accumulate during the dicing process, which is essential in preventing damage to sensitive semiconductor components. Conductive Films are often made from materials that allow for the controlled flow of electricity, such as certain metal-infused polymers. This type of film is crucial in environments where static discharge could lead to defects or failures in the final product. The choice between Non-Conductive and Conductive Dicing Films depends largely on the specific requirements of the semiconductor manufacturing process and the intended application of the final product. Manufacturers must carefully consider factors such as the electrical properties of the film, its adhesion strength, and its thermal resistance when selecting the appropriate type of dicing film for their needs. As the semiconductor industry continues to evolve, the demand for both Non-Conductive and Conductive Dicing Films is expected to grow, driven by the increasing complexity and miniaturization of electronic components. This growth is further supported by ongoing research and development efforts aimed at improving the performance and versatility of dicing films, ensuring they can meet the ever-changing demands of the semiconductor market.

Consumer Electronics, Industrial Electronics, Other in the Global Dicing Film Market:

The Global Dicing Film Market finds extensive usage across various sectors, including Consumer Electronics, Industrial Electronics, and other areas. In the realm of Consumer Electronics, dicing films play a critical role in the production of devices such as smartphones, tablets, and laptops. These films ensure that the delicate semiconductor components within these devices are protected during the manufacturing process, allowing for the production of high-performance, reliable consumer electronics. As consumer demand for more advanced and feature-rich devices continues to grow, the need for high-quality dicing films becomes increasingly important. In Industrial Electronics, dicing films are used in the production of components for a wide range of applications, including automation systems, industrial machinery, and control systems. These films help ensure the precision and reliability of the electronic components used in these applications, which is crucial for maintaining the efficiency and safety of industrial operations. The demand for dicing films in this sector is driven by the increasing adoption of automation and smart technologies in industrial settings, which require highly reliable and durable electronic components. Beyond consumer and industrial electronics, dicing films are also used in other areas such as automotive electronics, medical devices, and telecommunications. In the automotive industry, for example, dicing films are used in the production of electronic components for advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle powertrains. In the medical field, these films are used in the production of components for diagnostic equipment and wearable health devices. The telecommunications sector also relies on dicing films for the production of components used in networking equipment and communication devices. The versatility and reliability of dicing films make them an essential component in the manufacturing processes of various industries, supporting the production of high-quality, high-performance electronic devices.

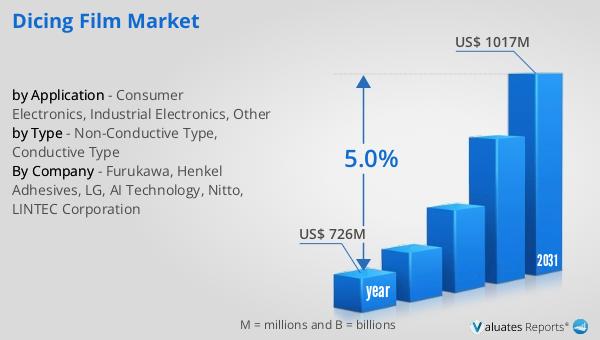

Global Dicing Film Market Outlook:

The outlook for the Global Dicing Film Market indicates a promising trajectory. In 2024, the market was valued at approximately US$ 726 million. Looking ahead, it is anticipated to expand significantly, reaching an estimated size of US$ 1017 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.0% over the forecast period. This upward trend reflects the increasing demand for dicing films driven by the expanding semiconductor industry and the growing need for advanced electronic devices across various sectors. The market's growth is supported by technological advancements and innovations in dicing film materials, which enhance their performance and application range. As industries continue to evolve and adopt more sophisticated technologies, the demand for high-quality dicing films is likely to rise, further propelling market growth. The projected expansion of the Global Dicing Film Market underscores the critical role these films play in the semiconductor manufacturing process and their importance in supporting the production of cutting-edge electronic devices. This positive market outlook highlights the opportunities for manufacturers and suppliers to capitalize on the growing demand for dicing films and to continue innovating to meet the evolving needs of the semiconductor industry.

| Report Metric | Details |

| Report Name | Dicing Film Market |

| Accounted market size in year | US$ 726 million |

| Forecasted market size in 2031 | US$ 1017 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Furukawa, Henkel Adhesives, LG, AI Technology, Nitto, LINTEC Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |