What is Global Rotary Union Market?

The Global Rotary Union Market is a dynamic and essential segment within the industrial equipment sector, focusing on the design, production, and distribution of rotary unions. These devices are crucial for transferring fluids such as water, oil, air, or steam from a stationary source to a rotating component. Rotary unions are used in various industries, including manufacturing, automotive, aerospace, and energy, to ensure efficient and reliable fluid transfer in machinery and equipment. The market is driven by the increasing demand for automation and advanced machinery across industries, which require reliable and efficient fluid transfer solutions. Technological advancements have led to the development of more durable and efficient rotary unions, catering to the specific needs of different industries. The market is characterized by a diverse range of products, including single-channel and multi-channel rotary unions, each designed to meet specific operational requirements. As industries continue to evolve and demand more sophisticated machinery, the Global Rotary Union Market is expected to grow, driven by innovation and the need for efficient fluid transfer solutions. The market's growth is also supported by the expansion of industries such as oil and gas, aerospace, and manufacturing, which rely heavily on rotary unions for their operations.

Single Channel, Multi Channel in the Global Rotary Union Market:

In the Global Rotary Union Market, single-channel and multi-channel rotary unions play pivotal roles, each serving distinct purposes based on the complexity and requirements of the applications they are used in. Single-channel rotary unions are designed to transfer one type of fluid or media at a time. They are typically used in applications where the transfer of a single fluid is required, such as in certain types of manufacturing equipment or machinery that require cooling or lubrication. These rotary unions are simpler in design and are often more cost-effective, making them suitable for applications where the transfer of multiple fluids is not necessary. On the other hand, multi-channel rotary unions are engineered to handle multiple fluids simultaneously. This capability is crucial in complex machinery and equipment where different types of fluids need to be transferred at the same time, such as in advanced manufacturing processes or in industries like aerospace and automotive, where different fluids are used for cooling, lubrication, and hydraulic functions. Multi-channel rotary unions are more complex in design and construction, often incorporating advanced sealing technologies to prevent cross-contamination of fluids and ensure efficient operation. The choice between single-channel and multi-channel rotary unions depends largely on the specific needs of the application, including the types of fluids being transferred, the operating conditions, and the level of complexity required. In industries where precision and efficiency are paramount, such as in semiconductor manufacturing or aerospace, multi-channel rotary unions are often preferred due to their ability to handle multiple fluids with precision and reliability. However, in applications where simplicity and cost-effectiveness are more important, single-channel rotary unions may be the better choice. The Global Rotary Union Market continues to innovate and evolve, with manufacturers developing new designs and technologies to meet the changing needs of industries. This includes the development of rotary unions with enhanced durability, efficiency, and the ability to operate under extreme conditions. As industries continue to demand more from their machinery and equipment, the role of rotary unions, both single-channel and multi-channel, becomes increasingly important. The market is expected to continue growing as industries seek more efficient and reliable solutions for fluid transfer, driven by the need for automation and advanced machinery. The ongoing advancements in technology and the increasing complexity of industrial processes are likely to further drive the demand for both single-channel and multi-channel rotary unions, as they provide the necessary solutions for efficient and reliable fluid transfer in a wide range of applications.

Semiconductor Equipment, Industrial Robot (Robot Arm), Machine Tool, Oil & Gas, Aerospace, Papermaking & Printing Equipment, Metal Processing Equipment, Plastic & Rubber Equipment, Others in the Global Rotary Union Market:

The Global Rotary Union Market finds extensive usage across a variety of industries, each with its unique requirements and challenges. In the semiconductor equipment industry, rotary unions are essential for the precise transfer of cooling fluids, which are critical for maintaining the optimal temperature of semiconductor manufacturing equipment. The high precision and reliability of rotary unions ensure that the delicate processes involved in semiconductor manufacturing are not disrupted by temperature fluctuations. In the realm of industrial robots, particularly robot arms, rotary unions facilitate the transfer of hydraulic fluids and other media necessary for the smooth and efficient operation of robotic systems. These unions enable the robots to perform complex tasks with precision and reliability, which is crucial in automated manufacturing environments. Machine tools also rely heavily on rotary unions for the transfer of cooling and lubrication fluids, which are vital for maintaining the performance and longevity of the tools. In the oil and gas industry, rotary unions are used in drilling equipment and other machinery to transfer various fluids under high pressure and extreme conditions. Their robust design and ability to handle harsh environments make them indispensable in this sector. The aerospace industry utilizes rotary unions in various applications, including in the transfer of hydraulic fluids in aircraft systems. The high reliability and precision of rotary unions are critical in ensuring the safety and efficiency of aerospace operations. In papermaking and printing equipment, rotary unions are used to transfer steam and other fluids necessary for the production processes. Their ability to handle high temperatures and pressures makes them ideal for these applications. Metal processing equipment also benefits from the use of rotary unions, which facilitate the transfer of cooling and lubrication fluids necessary for the efficient operation of machinery. In the plastic and rubber equipment industry, rotary unions are used to transfer heating and cooling fluids, which are essential for maintaining the optimal temperature during the manufacturing processes. Other industries, such as food and beverage, pharmaceuticals, and textiles, also utilize rotary unions for various fluid transfer applications, highlighting the versatility and importance of these devices in modern industrial operations. The Global Rotary Union Market continues to grow as industries seek more efficient and reliable solutions for fluid transfer, driven by the need for automation and advanced machinery. The ongoing advancements in technology and the increasing complexity of industrial processes are likely to further drive the demand for rotary unions, as they provide the necessary solutions for efficient and reliable fluid transfer in a wide range of applications.

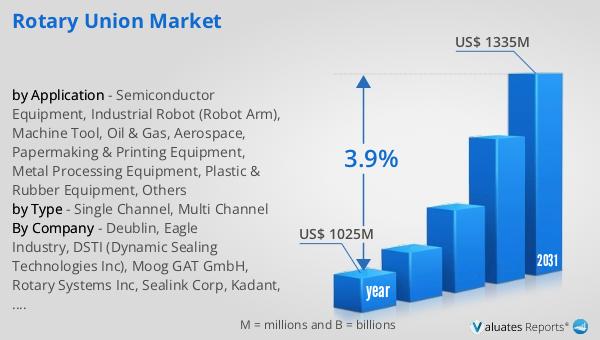

Global Rotary Union Market Outlook:

The global market for rotary unions was valued at approximately $1,025 million in 2024, and it is anticipated to expand to a revised size of around $1,335 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.9% over the forecast period. This steady growth is indicative of the increasing demand for rotary unions across various industries, driven by the need for efficient and reliable fluid transfer solutions. The market's expansion is supported by the ongoing advancements in technology and the increasing complexity of industrial processes, which require more sophisticated and efficient rotary unions. As industries continue to evolve and demand more from their machinery and equipment, the role of rotary unions becomes increasingly important. The market is expected to continue growing as industries seek more efficient and reliable solutions for fluid transfer, driven by the need for automation and advanced machinery. The ongoing advancements in technology and the increasing complexity of industrial processes are likely to further drive the demand for rotary unions, as they provide the necessary solutions for efficient and reliable fluid transfer in a wide range of applications. The market's growth is also supported by the expansion of industries such as oil and gas, aerospace, and manufacturing, which rely heavily on rotary unions for their operations.

| Report Metric | Details |

| Report Name | Rotary Union Market |

| Accounted market size in year | US$ 1025 million |

| Forecasted market size in 2031 | US$ 1335 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Deublin, Eagle Industry, DSTI (Dynamic Sealing Technologies Inc), Moog GAT GmbH, Rotary Systems Inc, Sealink Corp, Kadant, RIX CORPORATION, Rotoflux, Shenzhen Moflon Technology, Showa Giken Industrial, Duff - Norton, NMF Techniek BV, All Prosperity Enterprise Co Ltd, Haag + Zeissler Maschinenelemente GmbH, Christian Maier GmbH & Co. KG, OTT-JAKOB Clamping Technology GmbH, Scott Rotary Seals, Kwang Jin Corporation, SAEHAN, KJF Co., Ltd, Johnson- Fluiten, Korea Precision ENG Co., Ltd, Jiangsu Tengxuan Technology, Rotary Foremost, Rototech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |