What is Global Drive Sprockets Market?

The Global Drive Sprockets Market is a crucial segment within the broader mechanical components industry, focusing on the production and distribution of drive sprockets. These are toothed wheels that engage with a chain or track, playing a vital role in the transmission of rotary motion between two shafts where gears are unsuitable. Drive sprockets are essential in various machinery and vehicles, ensuring efficient power transfer and smooth operation. They are commonly used in bicycles, motorcycles, cars, and industrial machinery, where they help in converting rotational motion into linear motion or vice versa. The market for drive sprockets is influenced by factors such as technological advancements, the growth of the automotive and industrial sectors, and the increasing demand for efficient and durable mechanical components. As industries continue to evolve, the need for high-quality drive sprockets that can withstand wear and tear while maintaining performance is paramount. This market is characterized by a diverse range of materials, sizes, and designs to cater to the specific needs of different applications, making it a dynamic and essential part of the global mechanical components landscape.

Steel Material, Aluminum Material, Other in the Global Drive Sprockets Market:

In the Global Drive Sprockets Market, materials play a significant role in determining the performance, durability, and application suitability of the sprockets. Steel is one of the most commonly used materials due to its strength, durability, and resistance to wear and tear. Steel sprockets are ideal for heavy-duty applications where high strength and longevity are required. They are often used in industrial machinery, automotive applications, and other areas where the sprockets are subjected to high stress and harsh conditions. The robustness of steel makes it a preferred choice for applications that demand reliability and long service life. On the other hand, aluminum is another popular material used in the manufacturing of drive sprockets. Aluminum sprockets are known for their lightweight properties, which make them suitable for applications where weight reduction is crucial. They are often used in the automotive and aerospace industries, where reducing the overall weight of the vehicle or machinery can lead to improved performance and fuel efficiency. Aluminum sprockets also offer good resistance to corrosion, making them suitable for use in environments where exposure to moisture or chemicals is a concern. However, they may not be as durable as steel sprockets in high-stress applications. Apart from steel and aluminum, other materials such as plastics and composites are also used in the production of drive sprockets. These materials are typically used in applications where weight, cost, and noise reduction are more critical than strength and durability. Plastic sprockets, for example, are often used in light-duty applications where the load is not as significant, and the operating environment is less demanding. They offer advantages such as low cost, reduced noise, and resistance to corrosion. Composites, on the other hand, can offer a balance between strength and weight, making them suitable for specific applications where traditional materials may not meet the requirements. The choice of material for drive sprockets depends on various factors, including the specific application, environmental conditions, and performance requirements. Manufacturers in the Global Drive Sprockets Market continue to innovate and develop new materials and manufacturing processes to meet the evolving needs of different industries. This focus on material innovation ensures that drive sprockets remain a vital component in the efficient operation of machinery and vehicles across various sectors.

Automotive, Electronics, Aerospace And Defense, Metal Fabrication Industry, Industrial Machinery in the Global Drive Sprockets Market:

The Global Drive Sprockets Market finds extensive usage across several key industries, each with its unique requirements and challenges. In the automotive sector, drive sprockets are integral components in the transmission systems of vehicles. They help in transferring power from the engine to the wheels, ensuring smooth and efficient vehicle operation. The demand for high-performance and durable sprockets in this sector is driven by the need for reliable and efficient power transmission systems that can withstand the rigors of daily use. In the electronics industry, drive sprockets are used in various devices and machinery where precise motion control is required. They are often found in printers, copiers, and other office equipment, where they help in the accurate movement of paper and other materials. The need for precision and reliability in these applications makes drive sprockets an essential component in the electronics sector. The aerospace and defense industries also rely heavily on drive sprockets for various applications. In aerospace, they are used in aircraft systems where weight reduction and reliability are critical. The use of lightweight materials such as aluminum in sprockets helps in reducing the overall weight of the aircraft, leading to improved fuel efficiency and performance. In the defense sector, drive sprockets are used in military vehicles and equipment, where durability and performance under extreme conditions are paramount. The metal fabrication industry utilizes drive sprockets in machinery and equipment used for cutting, shaping, and assembling metal components. The need for precise and efficient motion control in these processes makes drive sprockets a vital component in ensuring the quality and accuracy of the final products. In industrial machinery, drive sprockets are used in a wide range of applications, from conveyor systems to heavy-duty machinery. They play a crucial role in the smooth and efficient operation of these machines, ensuring that they can handle the demands of industrial processes. The versatility and reliability of drive sprockets make them an indispensable component in the industrial sector. Overall, the Global Drive Sprockets Market serves a diverse range of industries, each with its specific needs and challenges. The ability of drive sprockets to provide reliable and efficient power transmission makes them a critical component in the operation of machinery and vehicles across these sectors. As industries continue to evolve and demand more efficient and durable components, the importance of drive sprockets in ensuring the smooth and efficient operation of machinery and vehicles will only continue to grow.

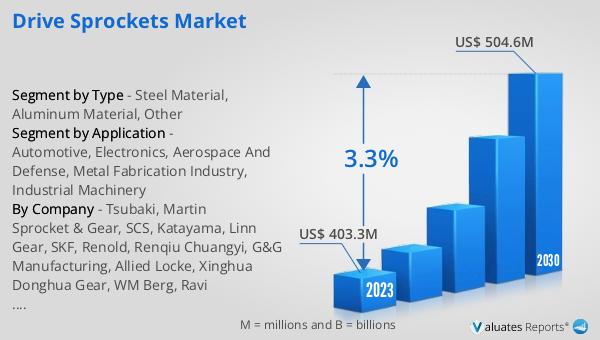

Global Drive Sprockets Market Outlook:

In 2024, the global market for drive sprockets was valued at approximately $428 million. Looking ahead, this market is expected to experience growth, reaching an estimated size of $535 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.3% over the forecast period. The steady increase in market size can be attributed to several factors, including the rising demand for efficient and durable mechanical components across various industries. As sectors such as automotive, aerospace, and industrial machinery continue to expand, the need for high-quality drive sprockets that can withstand wear and tear while maintaining performance becomes increasingly important. Additionally, advancements in materials and manufacturing processes are expected to contribute to the market's growth, as manufacturers strive to develop sprockets that offer improved performance and longevity. The projected growth of the Global Drive Sprockets Market reflects the ongoing demand for reliable and efficient power transmission solutions in a wide range of applications. As industries continue to evolve and seek more efficient and durable components, the importance of drive sprockets in ensuring the smooth and efficient operation of machinery and vehicles will remain a key driver of market growth.

| Report Metric | Details |

| Report Name | Drive Sprockets Market |

| Accounted market size in year | US$ 428 million |

| Forecasted market size in 2031 | US$ 535 million |

| CAGR | 3.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Tsubaki, Martin Sprocket & Gear, SCS, Katayama, Linn Gear, SKF, Renold, Renqiu Chuangyi, G&G Manufacturing, Allied Locke, Xinghua Donghua Gear, WM Berg, Ravi Transmission, Precision Gears, ABL Products, Sit S.p.A, B&B Manufacturing, Van Zeeland, Amec, Maurey |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |